Fabricated green building hoisting system based on BIM (Building Information Modeling) and use method thereof

A green building and prefabricated technology, which is applied in construction, building structure, and processing of building materials, etc., can solve problems such as falling wall panels and adverse effects on the personal safety of operators, so as to facilitate hoisting, reduce adverse effects, and The effect of small drop probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

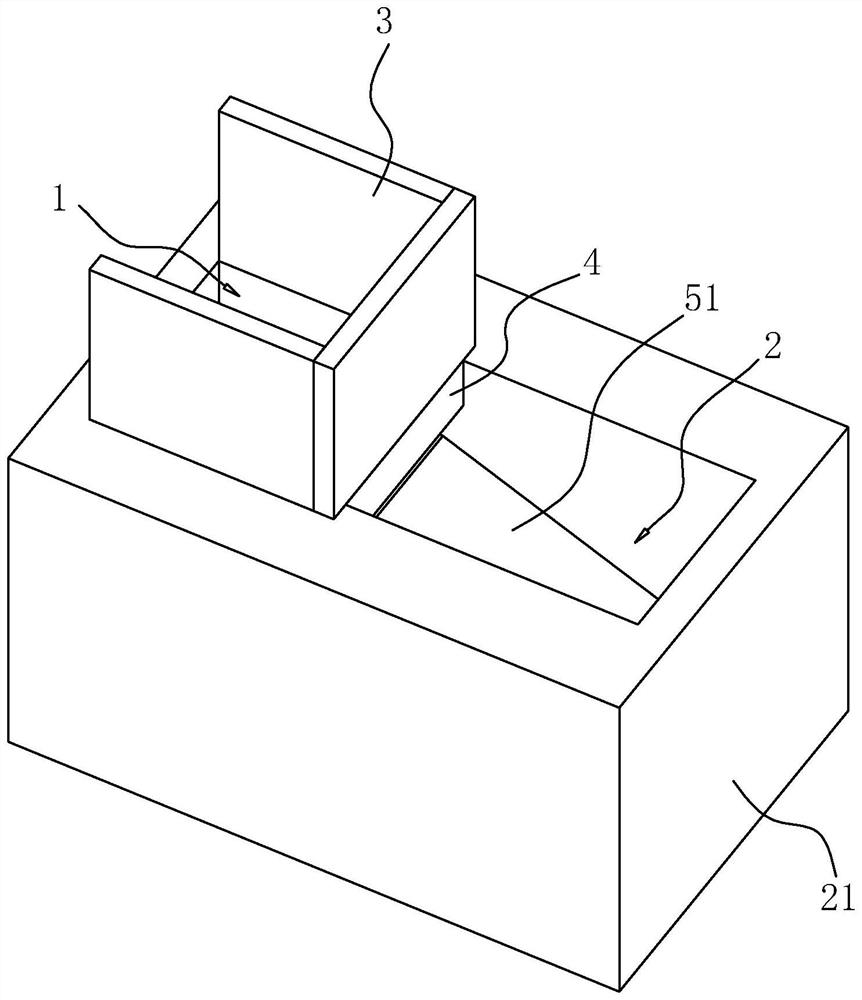

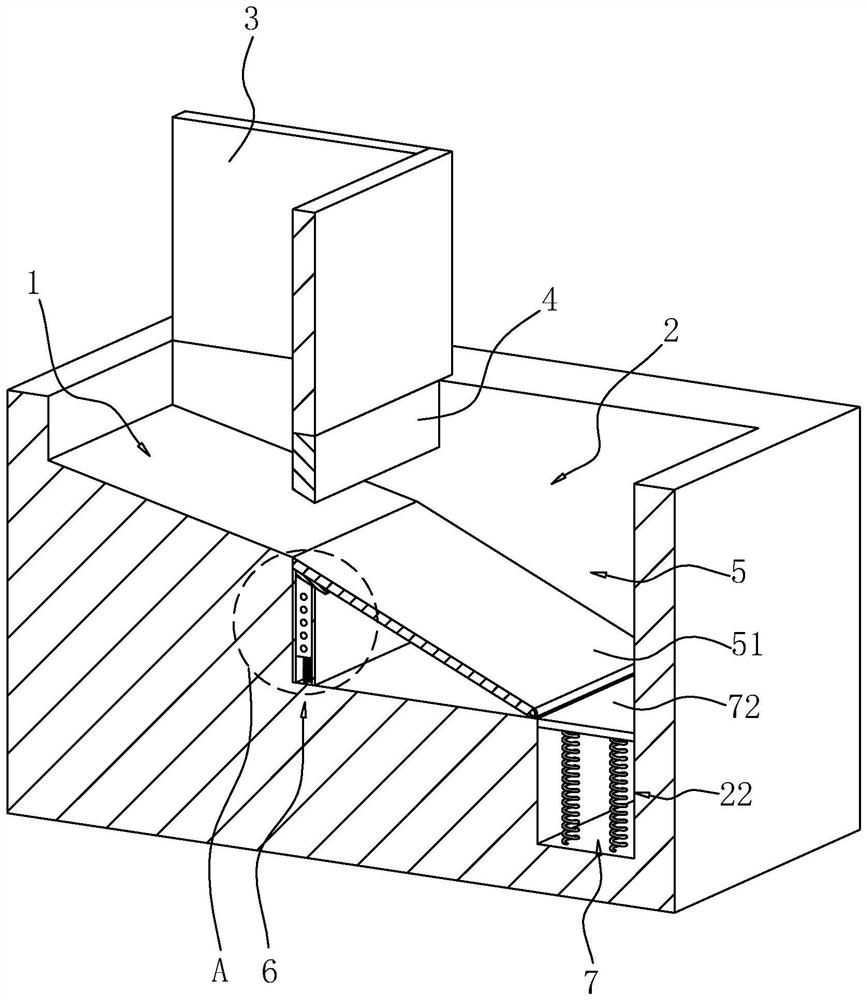

[0042] The following is attached Figure 1-5 The application is described in further detail.

[0043] The embodiment of the present application discloses a BIM-based prefabricated green building hoisting system. refer to figure 1 , The hoisting system includes an unloading cavity 1 and a transfer cavity 2 opened on the ground, the unloading cavity 1 communicates with the transfer cavity 2, and the depth of the transfer cavity 2 is greater than the depth of the unloading cavity 1. A feed bin 3 is fixedly connected to the bottom surface, the feed bin 3 is located above the lower material chamber 1, and the side of the feed bin 3 away from the transfer chamber 2 is open. The bottom wall of the unloading cavity 1 is inclined, and the side of the unloading cavity 1 away from the transfer cavity 2 is higher than the side of the unloading cavity 1 close to the transfer cavity 2 .

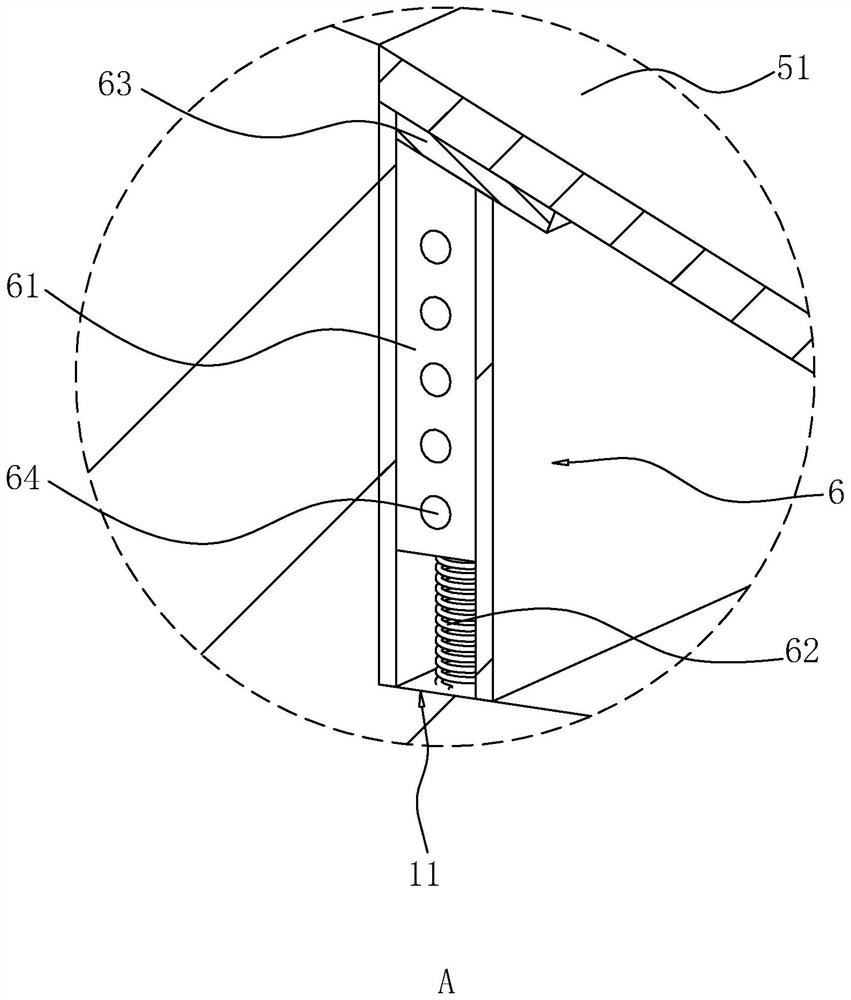

[0044] refer to figure 1 and figure 2 A baffle plate 4 is fixedly connected to the bottom surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com