Quick connector and working method thereof

A fast and end-to-end technology, applied in the direction of mechanical equipment, couplings, etc., can solve problems such as spending a lot of time and energy, connection deviation, etc., and achieve the effect of simple operation and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

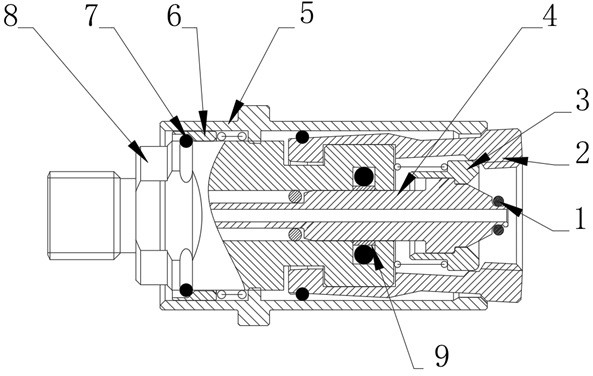

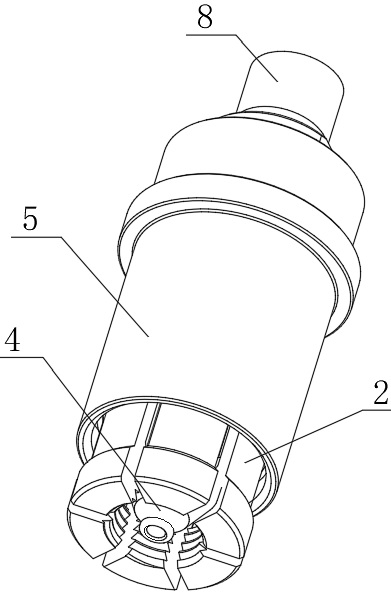

[0058] refer to Figure 1-8 As shown, the present invention provides a quick connector, the quick connector includes:

[0059] Quick connection housing 5, the quick connection housing 5 is cylindrical;

[0060] A joint 8, the joint 8 is located inside the quick-connect housing 5, and is inserted into the quick-connect valve core 4 at its front end;

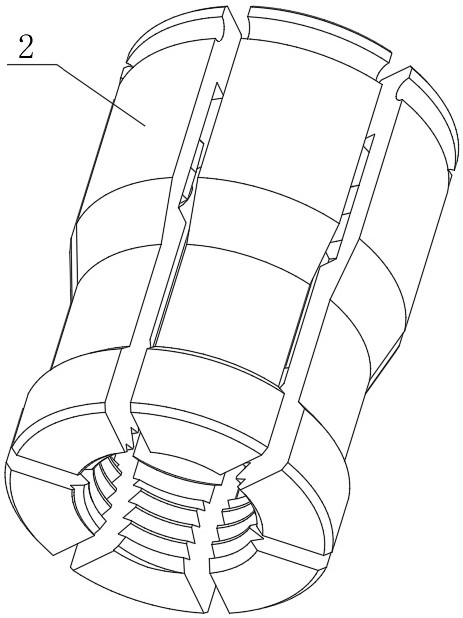

[0061] The sextant 2, the sextant 2 is sleeved at the end of the joint 8, and the sextant 2 is wrapped around the outside of the quick-connect valve core 4, the sextant 2 is squeezed inward when it is closed, and forming a threaded groove; and

[0062]The pressing sleeve 3 is sleeved on the outside of the quick-connect valve core 4 and fits with the inside of the sextant 2 .

[0063] refer to figure 1 As shown, the compression sleeve 3 and the joint 8 are connected by a spring.

[0064] refer to figure 1 As shown, the inner wall of the quick-connect housing 5 is provided with a retaining ring, and the retaining ring is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com