Siphon type fluid specific heat capacity measuring method

A measurement method and specific heat capacity technology, applied in the fields of fluid mechanics and thermals, which can solve problems such as large amount of calculation, complex calculation, and excessive operation of equipment, and achieve the effects of sufficient heat exchange between cold and hot fluids, clear physical principles, and simple data processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described.

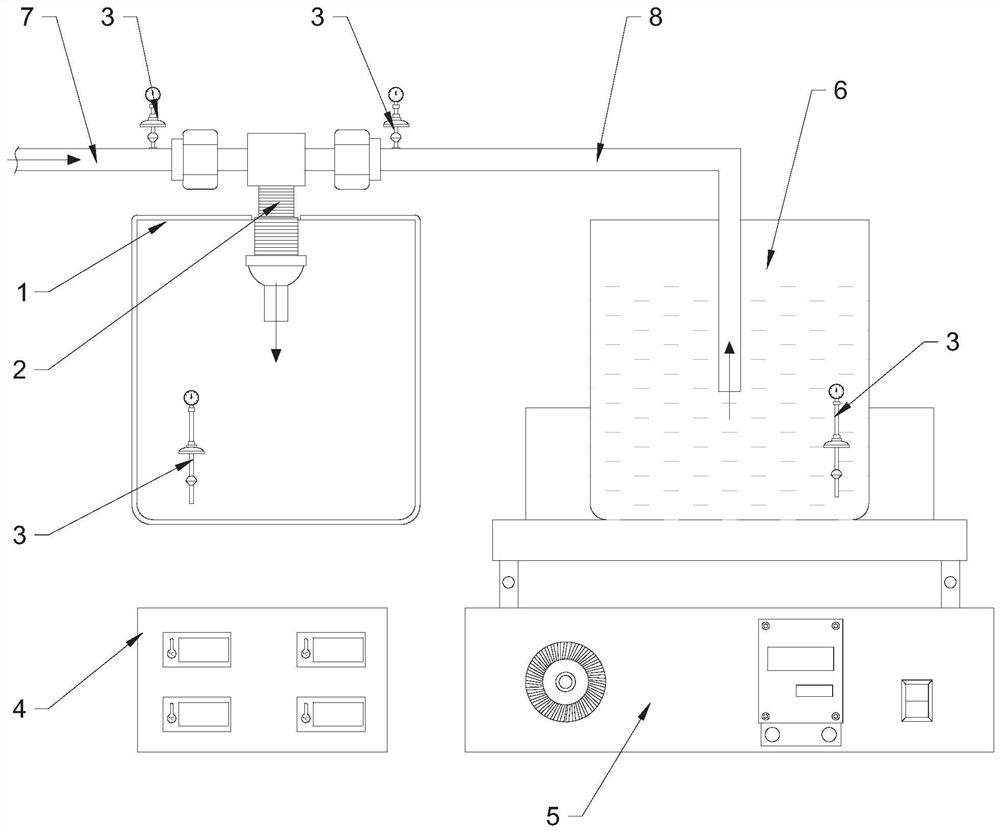

[0024] like figure 1 As shown, a siphon fluid specific heat capacity measurement method, the method utilizes the siphon effect to realize the rapid and full mixing of the working fluid and the fluid to be tested, and measures the temperature of the working fluid, the fluid to be tested, and the mixed fluid, and the temperature of the fluid to be tested and the mixed fluid. The quality of the fluid, according to the first law of thermodynamics, realizes the accurate determination of the specific heat capacity of the fluid to be measured. In the present invention, the working fluid and the fluid to be measured are gas, liquid, solution and other fluids.

[0025] The device used in the method of the present invention includes a mixing container 1 for containing the mixed fluid, a fluid container 6 for containing the fluid to be tested, and an atomizing nozzle 2 . The mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com