Demand response-oriented charging pile load intelligent regulation and control method and system

A demand response, charging pile technology, applied in power network operating system integration, AC network voltage adjustment, information technology support systems, etc., can solve problems such as adjusting charging pile feeders, solve overload problems, improve load balance, control high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

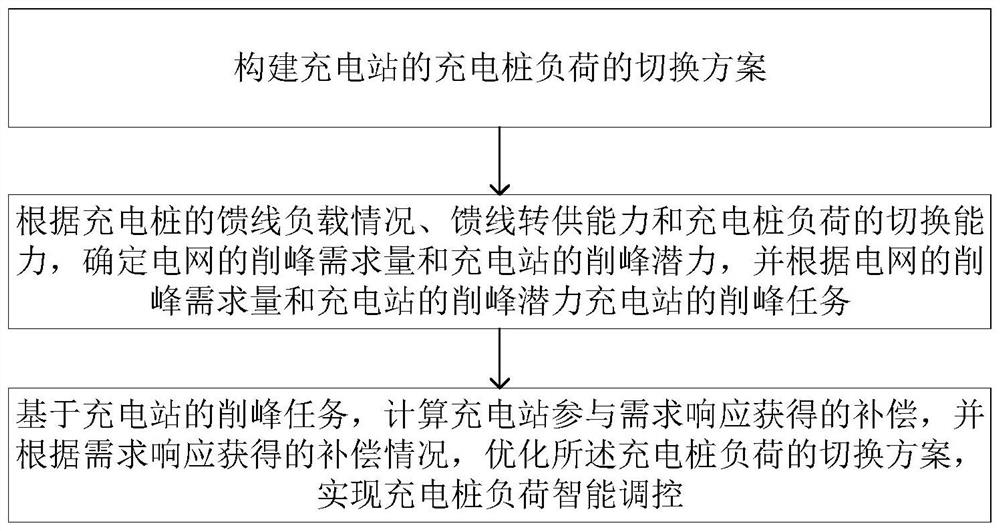

[0074] This embodiment proposes a demand response-oriented intelligent load control method for charging piles, including the following steps:

[0075] S1: Construct the switching scheme of the charging pile load of the charging station. The switching scheme of the charging pile load of the charging station is specifically as follows:

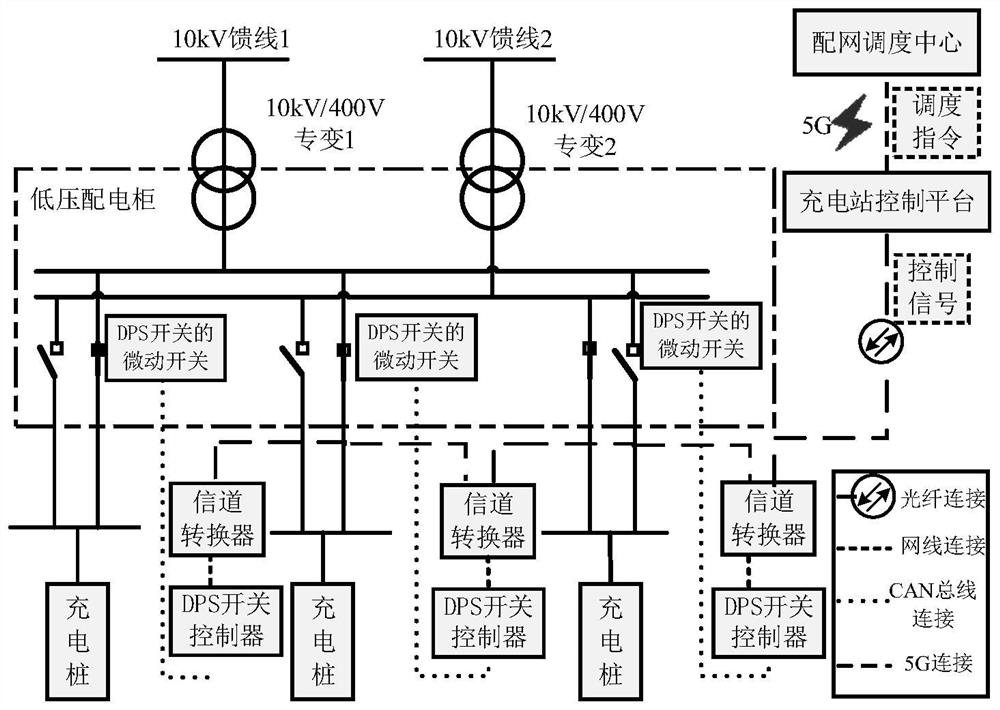

[0076] Each charging pile in the charging station is respectively connected with at least two DPS switches, and each of the DPS switches is respectively connected to a different special transformer, and the different special transformers are respectively connected to different feeders;

[0077] Under normal operation, the charging pile of the charging station is divided into two parts, respectively connected to two feeders; for a charging pile, the feeder connected under normal operation is called the common feeder of the charging pile, and the other feeders are called the charging pile. Under normal operation, for a charging pile, the DPS swit...

Embodiment 2

[0085] This embodiment proposes a demand response-oriented intelligent load control method for charging piles, including the following steps:

[0086] S1: Construct the switching scheme of the charging pile load of the charging station.

[0087] S2: Determine the peak-shaving demand of the grid and the peak-shaving potential of the charging station according to the load of the feeder of the charging pile, the transfer capacity of the feeder and the switching capacity of the charging pile Peak potential determines the peak shaving task of the charging station:

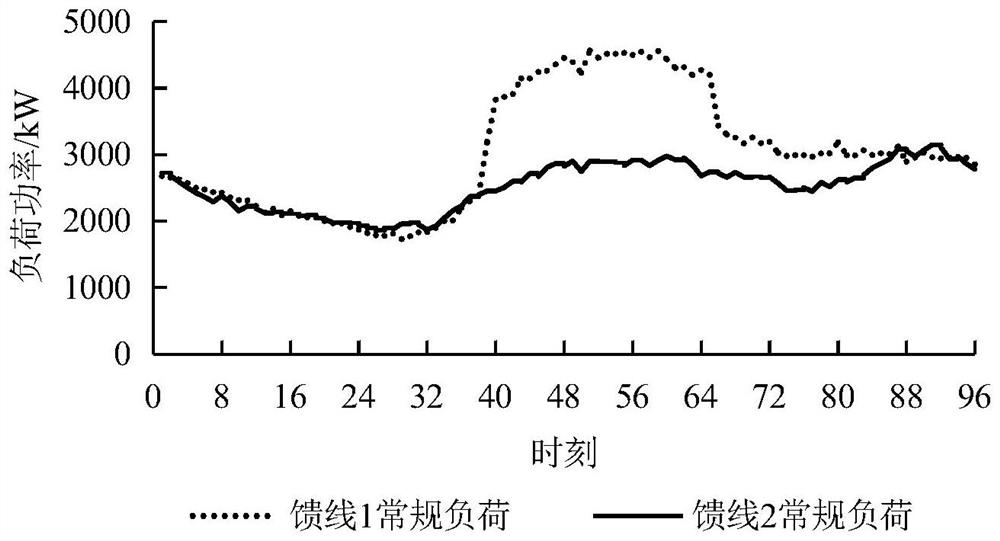

[0088] S2.1: The distribution network dispatching center determines the peak-shaving demand of the power grid according to the total load and load rate of the feeder connected to the charging station. During the peak-shaving period, the feeder that requires peak-shaving is recorded as the feeder that needs to be transferred, and the feeder that does not require peak-shaving is recorded as the feeder that can be transfe...

Embodiment 3

[0131] This embodiment also proposes a demand-response-oriented intelligent charging pile load evaluation method, which is applied to the demand-response-oriented charging pile load intelligent control method proposed in the above-mentioned embodiment 2, specifically including:

[0132] Calculate the peak-shaving effect of the feeder according to the peak-shaving rate of the feeder of the charging pile in the charging station, and evaluate the current charging pile load according to the peak-shaving effect of the feeder, wherein:

[0133] Define the reduction degree of the maximum load rate of the feeder after optimization relative to the maximum load rate of the feeder before optimization as the peak clipping rate of the feeder, then the peak clipping rate η of the feeder needs to be transferred wf The calculation formula of is as follows:

[0134]

[0135] Among them, λ wm_q Indicates the maximum load rate of the feeder before optimization, λ wm_h Indicates the maximum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com