Fibrous cellulose composite resin and method for producing same

A composite resin and cellulose technology, which is applied in plant fiber, fiber treatment, textiles and papermaking, etc., can solve the problem of fracture strain resin cracking or gaps, and achieve the effect of suppressing the reduction of fracture strain

Pending Publication Date: 2022-03-18

DAIO PAPER CORP

View PDF8 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Reduction in breaking strain can lead

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

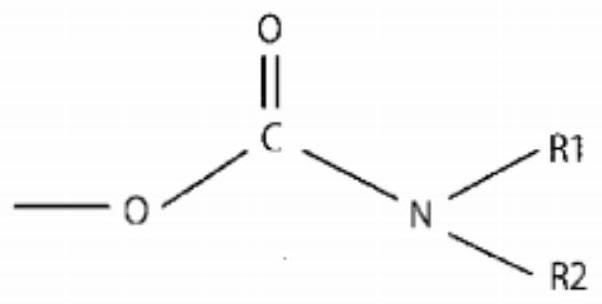

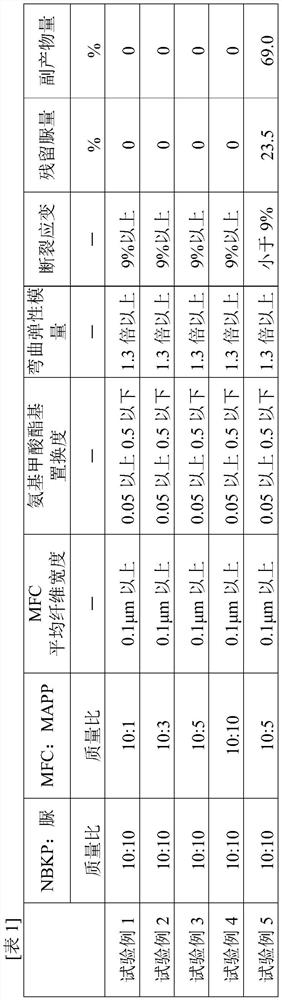

Provided are: a fibrous cellulose composite resin having high strength; and a method for producing the fibrous cellulose composite resin. The fibrous cellulose composite resin contains microfiber cellulose in which hydroxyl groups are replaced by urethane groups and washed, the microfiber cellulose is split to have an average fiber width of 0.1 [mu] m or more, and the average fiber width is 0.1 [mu] m or more per 100 parts by mass of the urethane-modified cellulose, a resin, and an acid-modified resin. And the amount of by-products is 10% or less. In addition, the production method comprises: a step in which a cellulose raw material and urea are heat-treated to obtain a urethane-modified cellulose; a step for cleaning the urethane-modified cellulose; a step for splitting the urethane-modified cellulose to obtain a dispersion of urethane-modified microfibrous cellulose having an average fiber width of 0.1 [mu] m or more; a step for mixing the dispersion liquid with an acid-modified resin to obtain a substance containing urethane-modified microfiber cellulose; and a step in which the resin is kneaded with the substance containing the urethane-modified microfiber cellulose to obtain a composite resin.

Description

Technical field [0001] The present invention relates to a fibrous cellulose composite resin and a method of producing thereof. Background technique [0002] In recent years, fine fibers such as cellulose nanofibers, microfibroblasts (microfibrillary cellulose) have received interest in the use of resin reinforcing materials. However, the fine fibers are hydrophilic, relative to it, and the resin is hydrophobic, and thus the fine fibers are used as a resin reinforcing material, and the dispersibility of the fine fibers has a problem. Thus, the inventors have proposed a solution of a hydroxyl group having a fine fiber using a urethane (see Patent Document 1). According to this scheme, the dispersibility of fine fibers is increased, so that the enhancement effect of the resin is improved. However, various studies are still continuing, such as whether the reduction in breaking strains can be suppressed. The reduction in breaking strain can cause rupture or gap of the resin. [0003] ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L1/08C08L23/26C08L23/12C08B15/06D06M13/432D06M101/06

CPCC08L1/08C08B15/06D06M13/432D06M2101/06C08L23/26C08L23/12C08J5/045C08J2300/105C08L101/08C08L23/14C08L2205/16C08L51/06C08L1/02C08L101/00C08J3/005C08J2323/12C08J2401/08C08J2423/26C08L2205/025C08L2205/03D21C1/08

Inventor 松末一紘今井贵章落合优

Owner DAIO PAPER CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com