Mixing device provided with closed sterilization assembly and used for food additive production and implementation method of mixing device

A technology of food additives and mixing devices, applied in the direction of mixing methods, mixers with rotating stirring devices, chemical instruments and methods, etc., can solve the problems of reduced sterilization effect, uneven mixing, incomplete sterilization of food additive raw materials, etc. problems, to achieve the effect of improving the sterilization effect, facilitating disinfection and mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0054] Another technical solution proposed by the present invention: providing an implementation method of a mixing device provided with a closed sterilization assembly for the production of food additives, comprising the following steps:

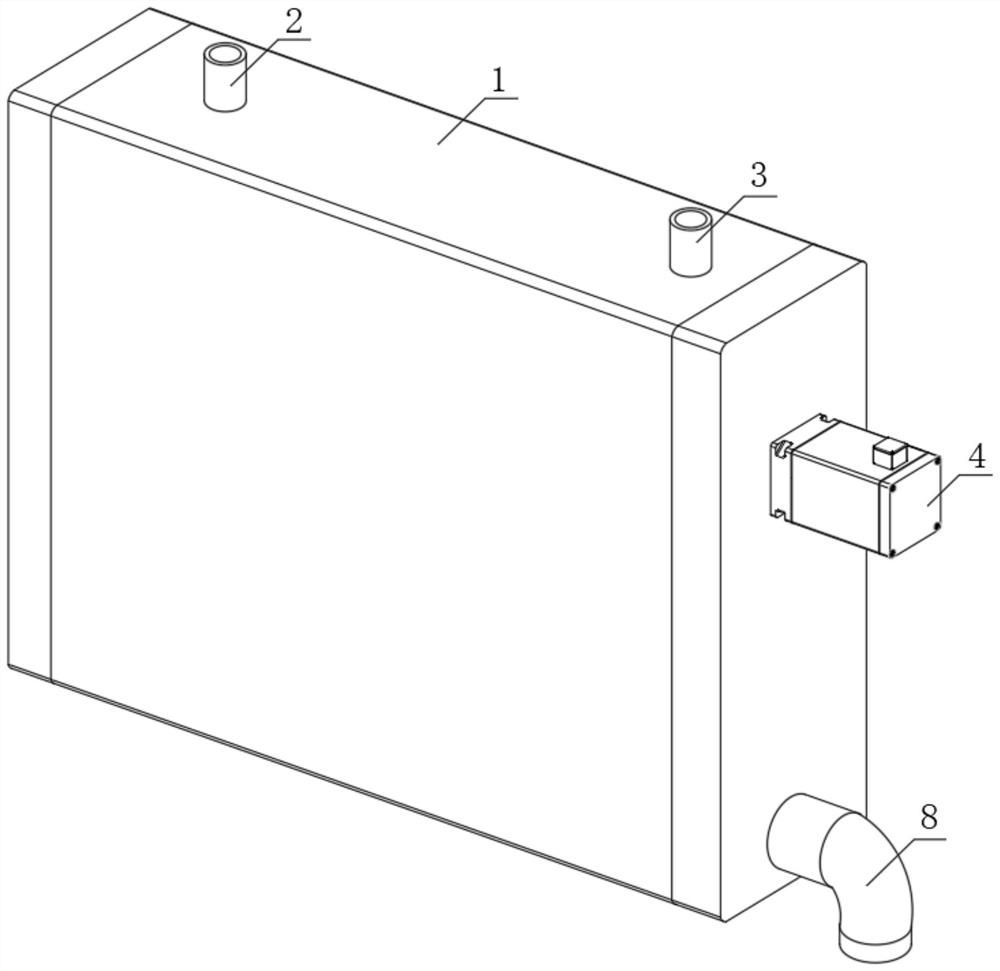

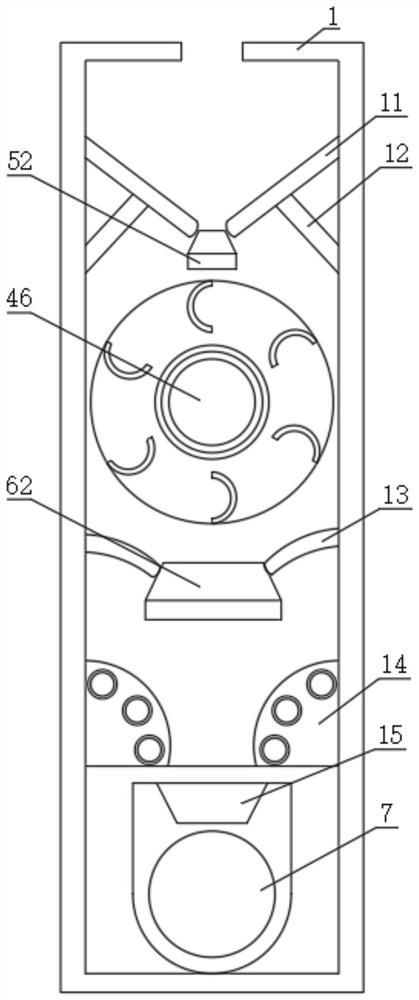

[0055] Step 1: Inject different food additive raw materials into the upper end of the conical material guide 11, and open the material guide port sealing mechanism 5 under the gravity of the food additive raw materials until the stirring and disinfection mechanism 4 is covered by two-thirds , at this moment, the discharge port blocking mechanism 6 is still in a closed state;

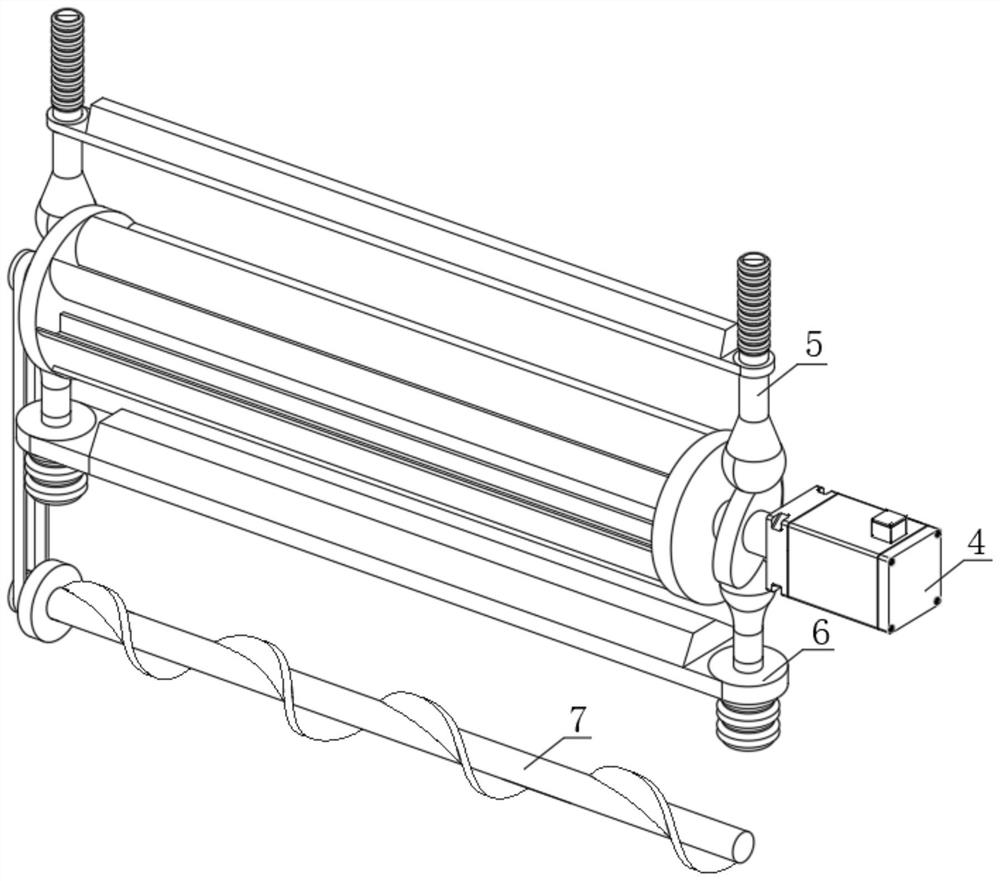

[0056] Step 2: When the tapered ends of the first cam 43 and the second cam 49 are away from the material guide drive head 511, under the reset action of the first return spring 513, the material guide drive head 511 moves upwards, and the conical guide material The outlet of piece 11 is opened, and the material flows out;

[0057] Step 3: The servo motor 41 starts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com