Digital jet printing machine for finished clothes

A printing machine and clothing technology, applied in printing, typewriters, etc., can solve problems such as ink cartridge outlet blockage, disconnection, cumbersome cleaning of ink cartridge outlet, etc., to reduce the possibility of disconnection or ink out, and reduce The effect of the probability of color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

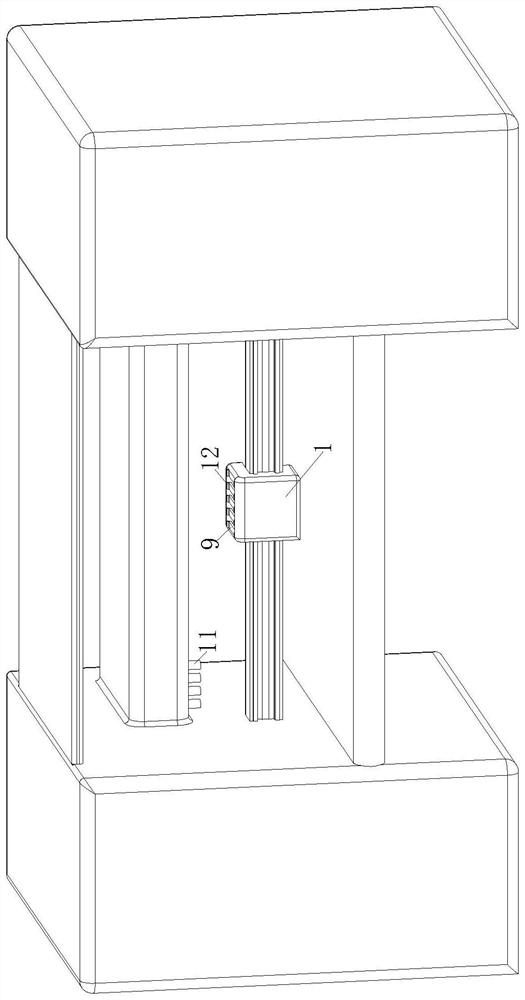

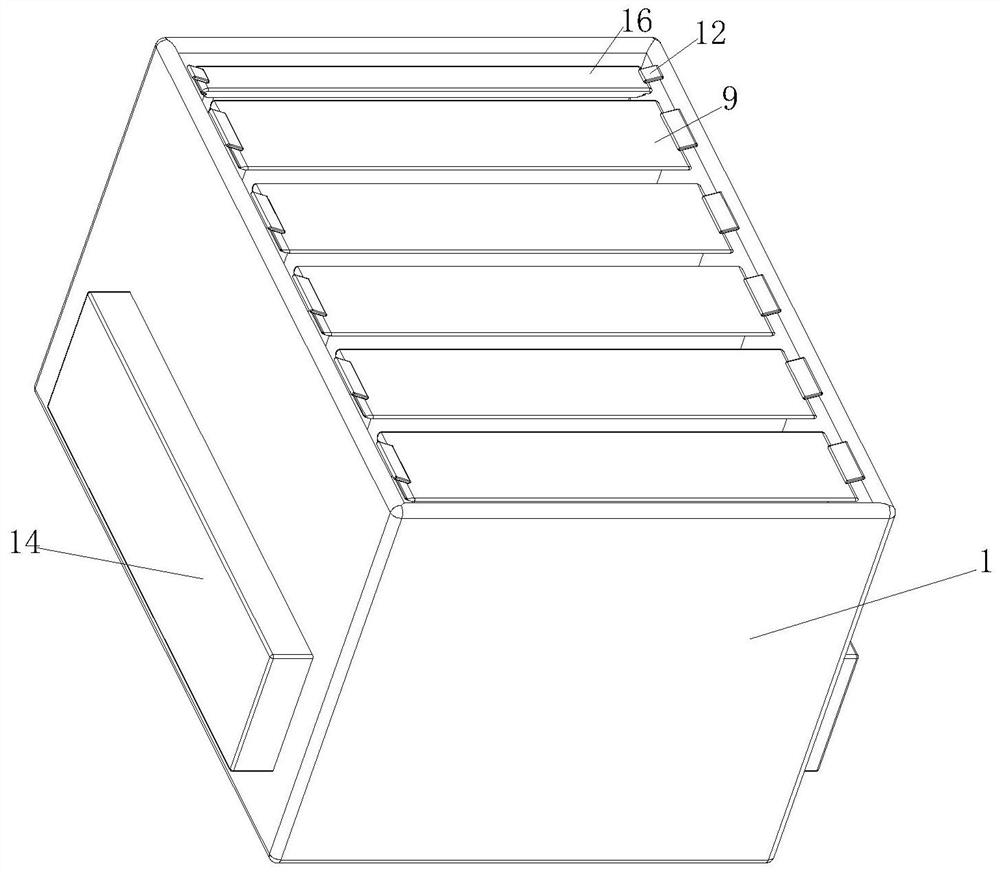

[0040] As a specific embodiment of the present invention, the top inner wall of the ink cartridge 1 is hingedly connected to the movable baffle 12;

[0041] The inner side of the bottom of the second engaging block 58 is provided with a light sensor 54; the inside of the first engaging block 57 is provided with an electric heating element 55; the electric heating element 55 is controlled by the light sensor 54;

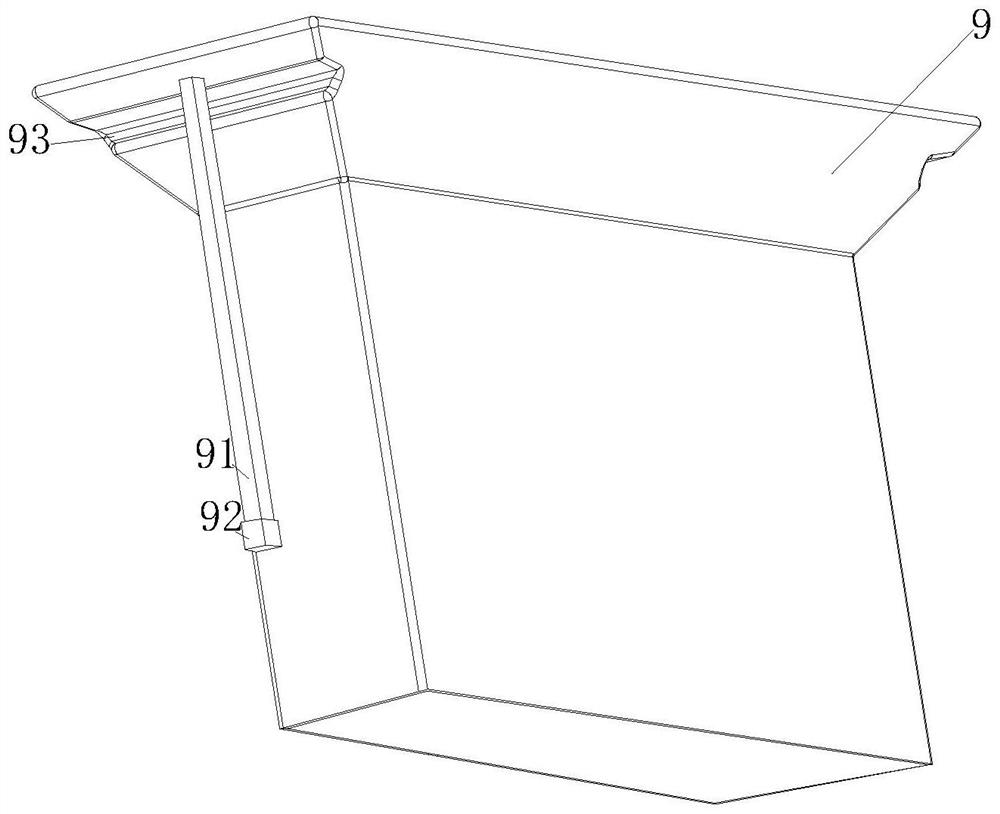

[0042] The support shaft 4 is provided with a memory metal 41 inside; the memory metal 41 is fixedly connected to the top of the No. 1 engaging block 57, and the memory metal 41 is provided with a No. 2 liquid hole 42, and the memory metal 41 is in the initial state. No. liquid through hole 42 is closed, opens when being heated back to the original state.

[0043] When the ink bag 9 is out of ink and needs to be replaced, when the ink liquid in the ink bag 9 is lower than the light sensor 54 in the second engagement block 58, the light sensor 54 will give signals to eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com