High-elastic wave wrinkled fabric and weaving process thereof

A technology of elastic wrinkle and fabric, which is applied in the direction of textiles, papermaking, textiles, fabrics, etc. It can solve the problems of poor comfort and air permeability, no large concave-convex effect, general hand feeling, etc., achieve fluffy and soft hand feeling, and prevent edge detachment , unique wavy appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation: Sectional warping, the tension of the tension sheet is 7, 8, 9, and the maximum tension is 3300N to draw the shaft.

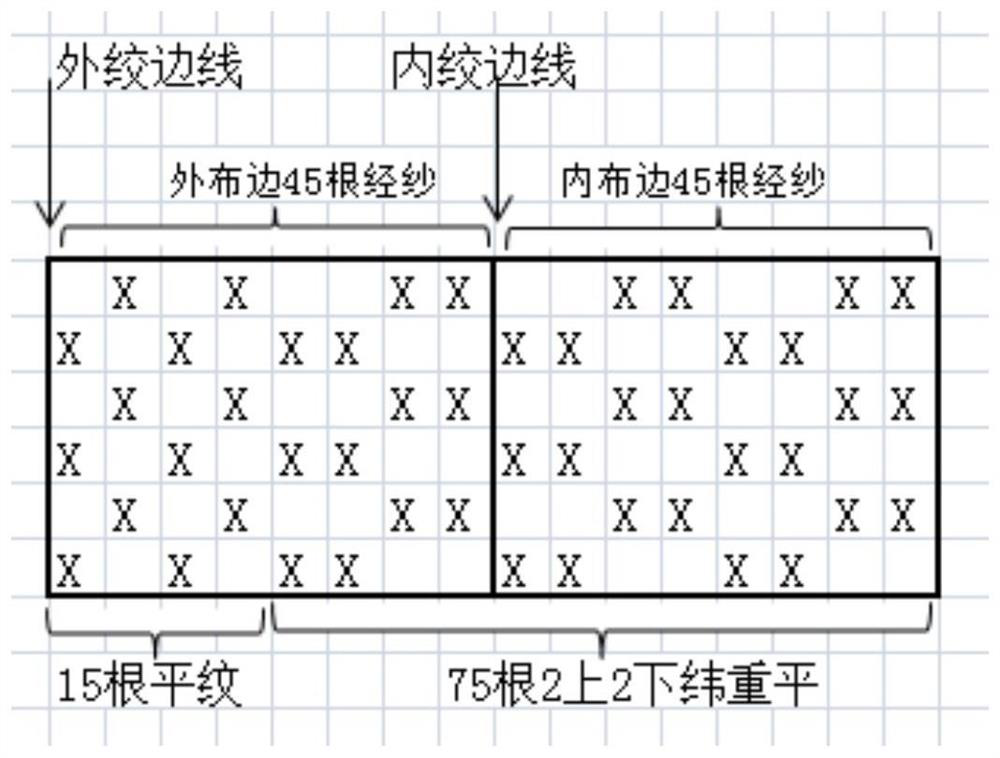

[0035] Yarn selection: 32 / 2C pure cotton yarn and 32S / 2C covered 40D spandex core-spun yarn are used for the warp yarn; 21S / C pure cotton yarn and 32S / 2C covered 40D spandex core-spun yarn are used for the weft yarn; the upper warp yarn and the lower layer The warp yarns are arranged in a ratio of 198:4 between the pure cotton yarn group and the spandex core-spun yarn group; the upper layer weft yarn and the lower layer weft yarn are arranged in a ratio of 119:3 according to the pure cotton yarn group and the spandex core-spun yarn group; The number of spandex core-spun yarns in the spandex core-spun yarn group at the edge is 8, and the weft yarn is 6;

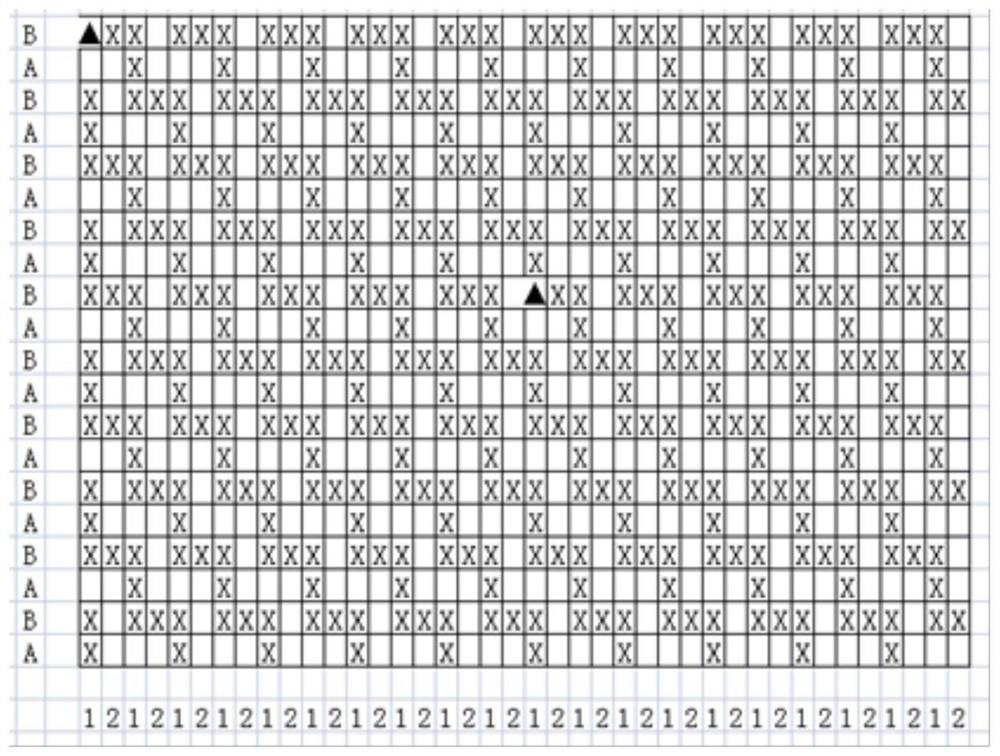

[0036] Weaving: Divide the warp yarn and weft yarn into upper and lower layers respectively, arrange the pure cotton yarn and spandex core-spun yarn according to the above rules respectively...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap