Clean room capable of being quickly assembled

A clean room, fast technology, applied in the field of clean room, can solve the problems such as cumbersome assembly of clean room, and achieve the effect of good environmental foundation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

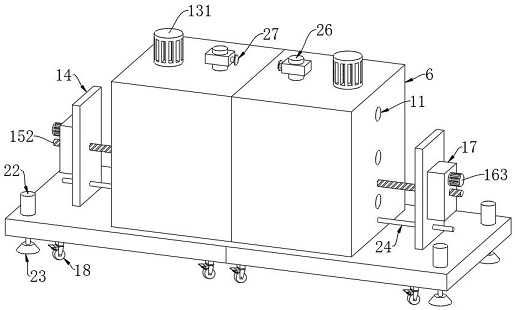

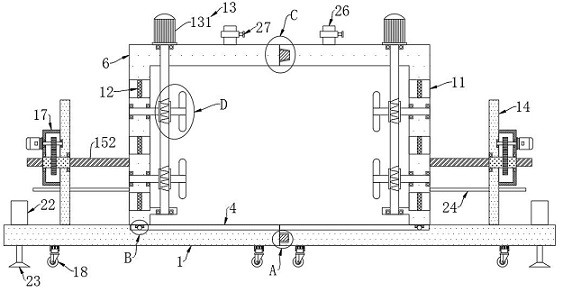

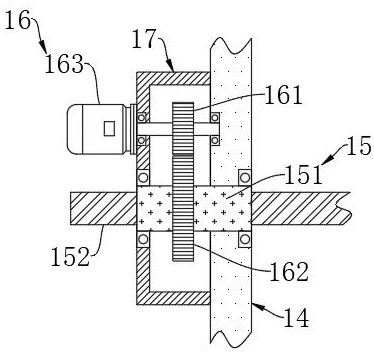

[0029] Such as Figure 1-8 As shown, a clean room that can be quickly assembled includes two bases 1, and a plurality of universal wheels 18 are fixedly connected to the base 1, and the universal wheels 18 can be self-locking. The setting of the universal wheels 18 is convenient for users The mobile base 1 is fixedly connected with a support block 19 on the universal wheel 18, and the support block 19 is slidably connected with a hollow slider 20, and a plurality of buffer springs 21 are fixedly connected between the support block 19 and the hollow slider 20, and the hollow slide One end of the block 20 away from the universal wheel 18 is fixedly connected to the base 1 , and the cooperation of the hollow slider 20 and the buffer spring 21 can utilize the deformation of the buffer spring 21 to buffer the vibration generated during the movement of the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com