Vacuum brazing process of an aluminum plate-fin oil-water composite cooler

A composite cooling and brazing process technology, applied in the field of brazing process and vacuum brazing process, can solve the problems of less than 20% of the first-time yield, lack of in-depth influence rules, late start and other problems, and achieve good microstructure and welding seam. quality, improve the quality of brazing, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A vacuum brazing process for an aluminum plate-fin oil and water composite cooler includes the following steps:

[0026] (1) Fin molding, parts cleaning, and parts assembly molding;

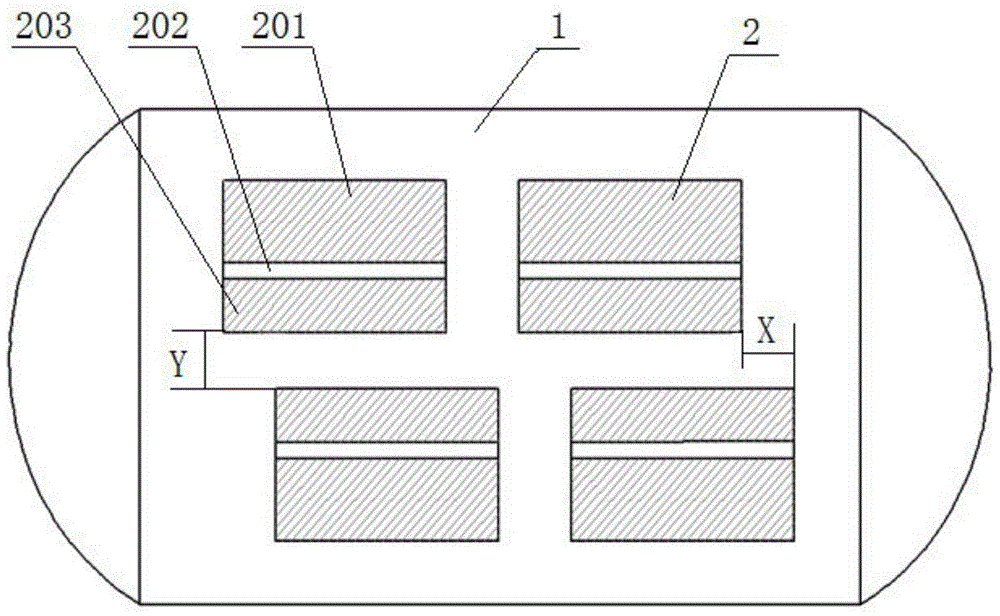

[0027] (2) Core placement: such as figure 1 As shown, since the cooler core 2 is divided into an oil cavity 201 and a water cavity 203, and the thickness structure of the oil cavity 201 and the water cavity 203 is quite different, there is an intermediate channel 202 between the oil cavity 201 and the water cavity 203 It is difficult to maintain the uniform temperature of the cooler core 2 during brazing. In order to improve the brazing uniformity of the cooler core 2, it needs to be staggered in the furnace cavity 1. The dislocation distance of the product end surface is X, X is not Less than 150mm, the distance between the windward surfaces of the two rows of product water chambers is Y, and Y is not less than 50mm;

[0028] In the core placement step, the dislocation distance X of the end fac...

experiment example 1

[0044] Taking the production of 5 batches of 800 sets of oil and water composite coolers as an example, the specific test content and data are as follows.

[0045] Experiment content: clean the cooler, dry it in a constant temperature and humidity drying room after cleaning, and then assemble and calibrate to ensure that the height of each part is within the tolerance range, the cleanliness of the parts meets the requirements, and the matching gap between the parts is 0.1 Within mm, the cooler core 2 is placed in the furnace cavity 1 according to the placement method described in the embodiment, and vacuum brazing is carried out according to the process parameters shown in Table 1, and the air tightness test and blasting are carried out after brazing. Test detection and fatigue strength detection, the test results are shown in Table 2, Table 3, and Table 4.

[0046] Table 1 Brazing conditions

[0047] Temperature section Temperature rise / fall time Holding time Vacuum degree / Pa ...

experiment example 2

[0058] Taking the production of 5 batches of 800 sets of oil and water composite coolers as an example, the specific test content and data are as follows.

[0059] The content of the experiment is the same as that of Test Example 1. Vacuum brazing is performed according to the process parameters shown in Table 5. After brazing, air tightness test detection, blasting test detection and fatigue strength detection are performed. The test results are shown in Table 6, Table 7, and Table 8. Show.

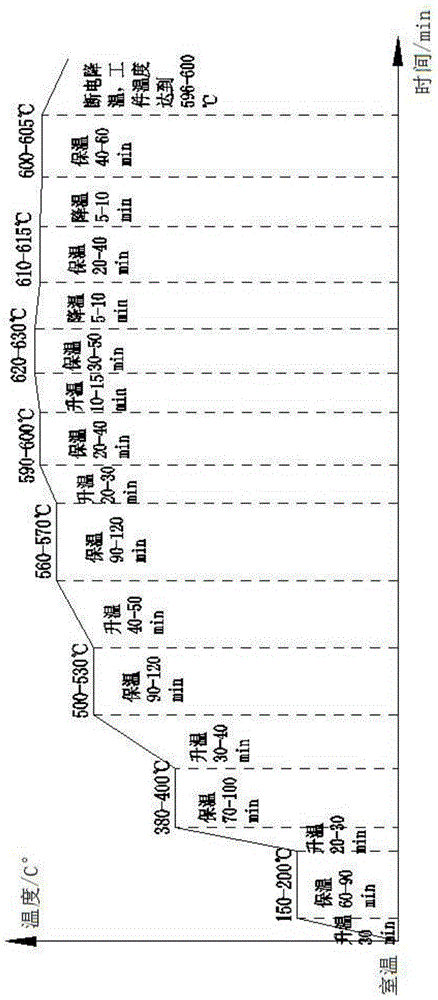

[0060] Table 5 Brazing conditions

[0061] Temperature section Temperature rise / fall time Holding time Vacuum degree / Pa 150-200℃ 30min 80-90min(4.0-4.5)×10 -2

380-400℃ 40min 90-100min(7.0-8.0)×10 -3

500-530℃ 50min 90-100min(4.0-5.0)×10 -3

560-570℃ 20min 110-120min(2.0-3.0)×10 -3

590-600℃ 15min 30-40min(1.0-2.0)×10 -3

620-630℃ 10min 35-45min(0.9-1.0)×10 -3

610-615℃ 5min 30-40min2.0×10 -3

600-605℃ 5min 40-50min1.5×10 -3

[0062] The test results are as follows:

[0063] Table 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bursting strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com