Differential fatigue durability rack spectrum compilation method and system, terminal and storage medium

A technology of durable platform and differential, which is applied in the direction of instruments, special data processing applications, electrical digital data processing, etc. It can solve the problems of unfavorable light weight, failure to achieve the purpose of pre-verification, and excessive load spectrum, etc., to achieve road coverage The effects of comprehensive types and accurate load input strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

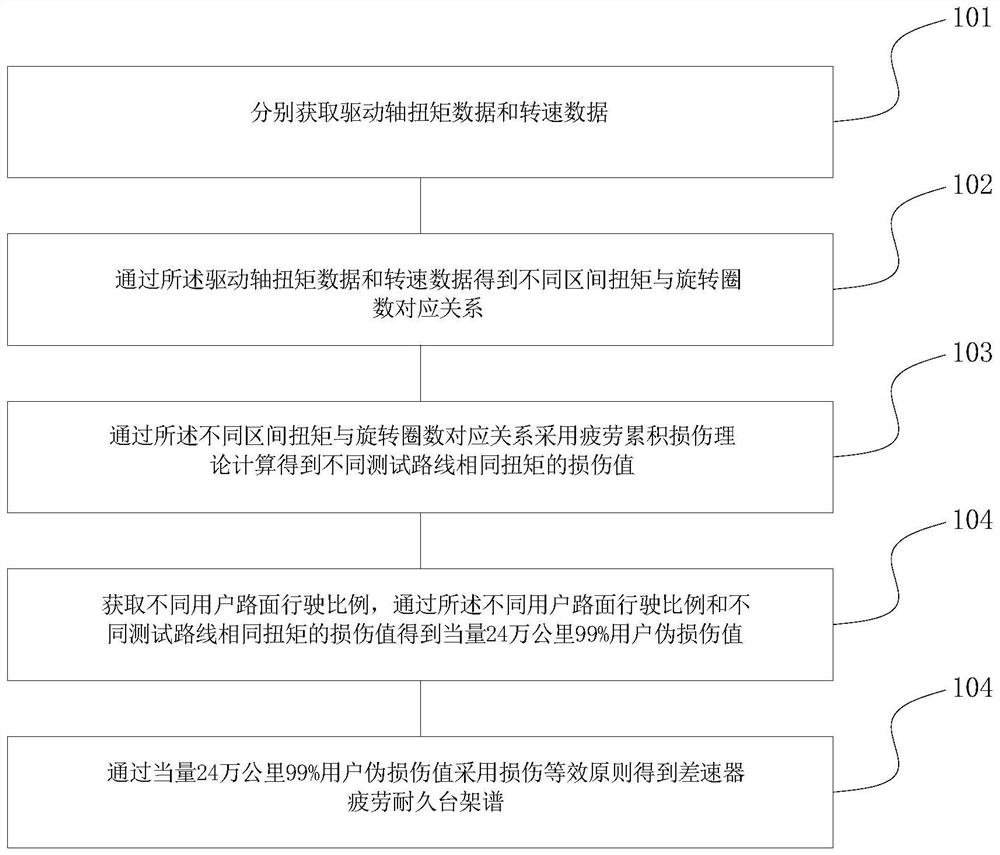

[0059] figure 1 It is a flow chart of a method for formulating a differential fatigue endurance bench spectrum according to an exemplary embodiment. The method is used in a terminal, and the method includes the following steps:

[0060] Step 101, acquiring drive shaft torque data and rotational speed data respectively;

[0061] Step 102, obtain the corresponding relationship between the torque in different intervals and the number of rotations through the torque data and rotational speed data of the drive shaft;

[0062] Step 103: Calculate the damage value of the same torque in different test routes through the corresponding relationship between the torque in different intervals and the number of rotations by using the theory of fatigue cumulative damage;

[0063] Step 104, obtain the road driving ratio of different users, and obtain the pseudo damage value of 99% users equivalent to 240,000 kilometers through the road driving ratio of different users and the damage value of...

Embodiment 2

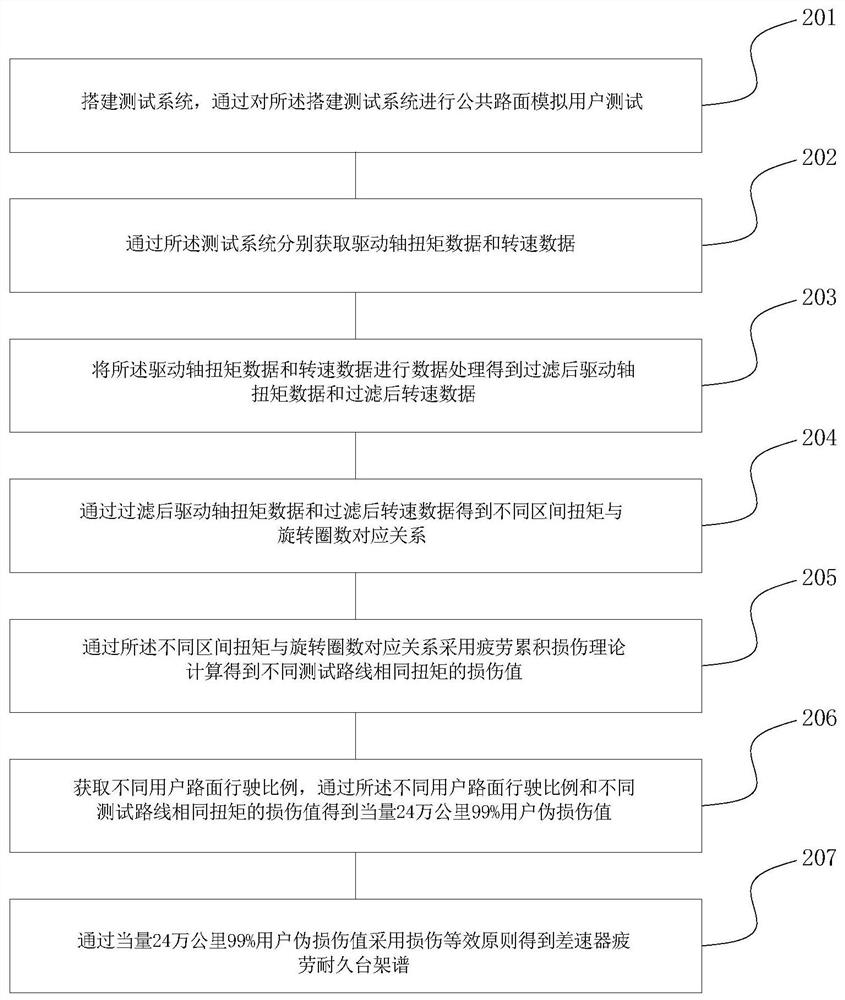

[0082] figure 2 It is a flow chart of a method for formulating a differential fatigue endurance bench spectrum according to an exemplary embodiment. The method is used in a terminal, and the method includes the following steps:

[0083] Step 201, building a test system, and performing a public road simulation user test on the built test system;

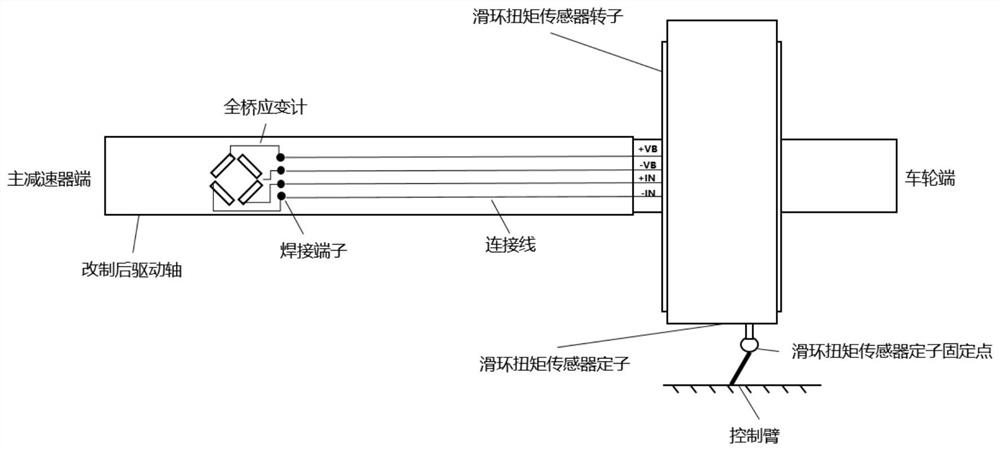

[0084] According to the direct size and installation position of the slip ring torque sensor installation hole, the diameter of the drive shaft near the wheel end is reduced to form a clearance fit with the slip ring torque sensor installation hole, and the middle gap is fixed with two-in-one adhesive to make the slip ring torque sensor The rotor is integral with the drive shaft and rotates together.

[0085] Install the strain gauge on the unmodified part of the drive shaft. Choose a full-bridge strain gauge for the strain gauge. Polish the surface of the installation position to make it smooth. Use special CN glue to stick the str...

Embodiment 3

[0132] In an exemplary embodiment, there is also provided a differential fatigue durability bench spectrum compilation system, such as Image 6 shown, including:

[0133] An acquisition module 310, configured to acquire drive shaft torque data and rotational speed data respectively;

[0134] The calculation module 320 is used to obtain the corresponding relationship between torque and the number of rotations in different intervals through the drive shaft torque data and rotational speed data;

[0135] The statistical module 330 is used to calculate the damage value of the same torque in different test routes by using the fatigue cumulative damage theory through the corresponding relationship between the torque in different intervals and the number of rotations;

[0136] The calculation module 340 is used to obtain the road driving ratio of different users, and obtain the pseudo damage value of 99% users equivalent to 240,000 kilometers through the road driving ratio of differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com