Large-current transmission connector structure based on spring

A connector and high-current technology, which is applied in the direction of connection, fixed/insulated contact components, circuits, etc., can solve the problems of difficult seal design for current transmission, small installation space, and large plugging force, etc., to solve the problem of large current transmission in a small space Difficult problems, strong overcurrent capability, and the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred mechanism and motion implementation of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

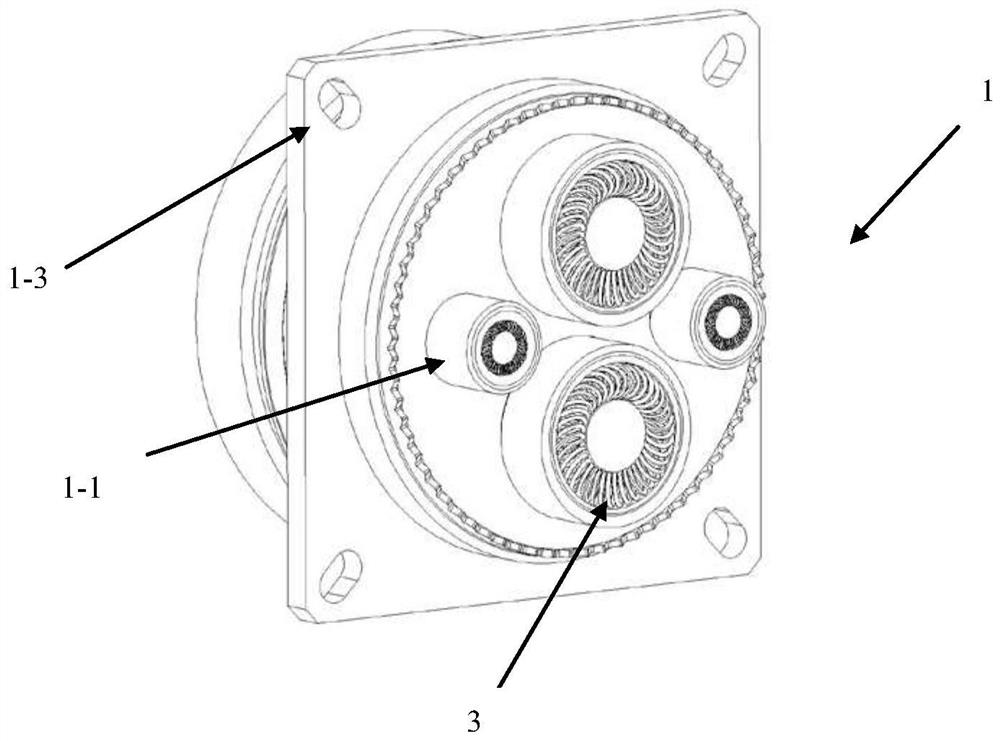

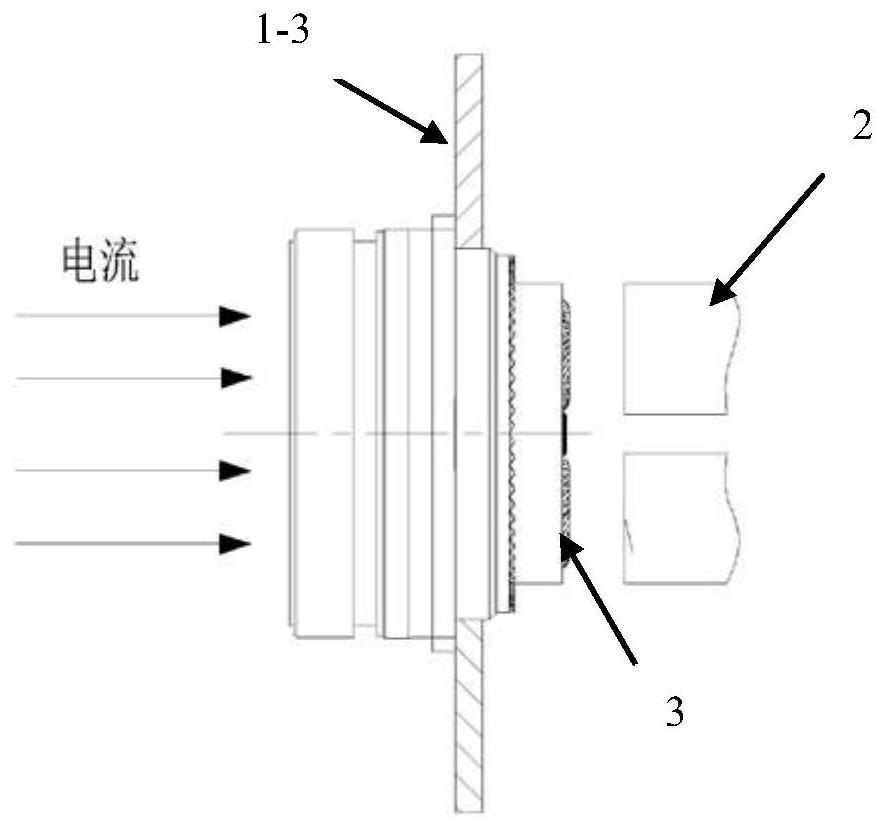

[0025] Such as Figure 1-6 As shown, it is a connector structure based on a spring-based large current transmission, the large current transmission connector, which includes a circular connector, including a connector plug end 1, and a connector tail end 2, the connector plug. The end 1 and the connector tail end 2 are mounted on the power supply device and the power supply device, and the connectors here can be another connector, or may be directly powered equipment.

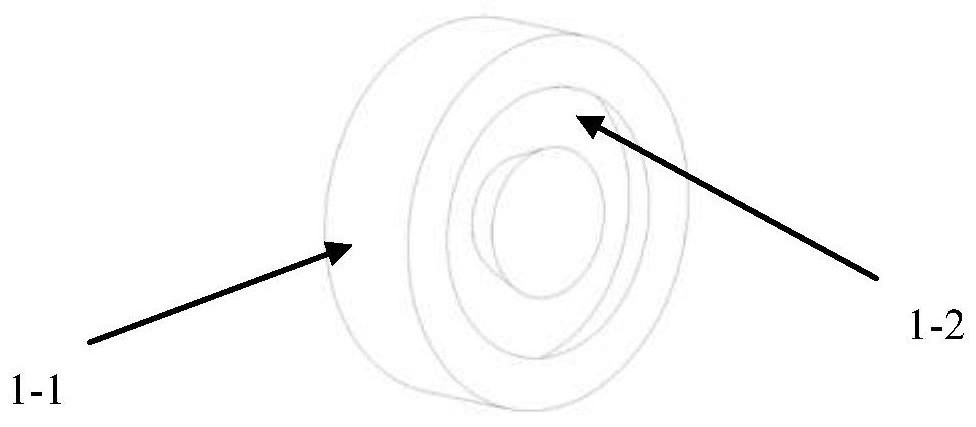

[0026] A plurality of terminals 1-1 are provided on the end face of the connector plug end 1, and an end surface of the terminal 1-1 is provided with an annular dovetail groove 1-2, and a ring-shaped coil spring is provided in the swallout tank 1-2. 3, the helical cross section of the annular coil spring 3 is an elliptical shape, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com