Impurity removing equipment for main food materials of sauced meat

A technology for stewed meat and staple food, which is applied in the field of impurity removal equipment, can solve the problems of low impurity removal rate, energy waste, and low practical performance, and achieve the effect of improving the impurity removal rate, improving the washing effect, and improving the practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

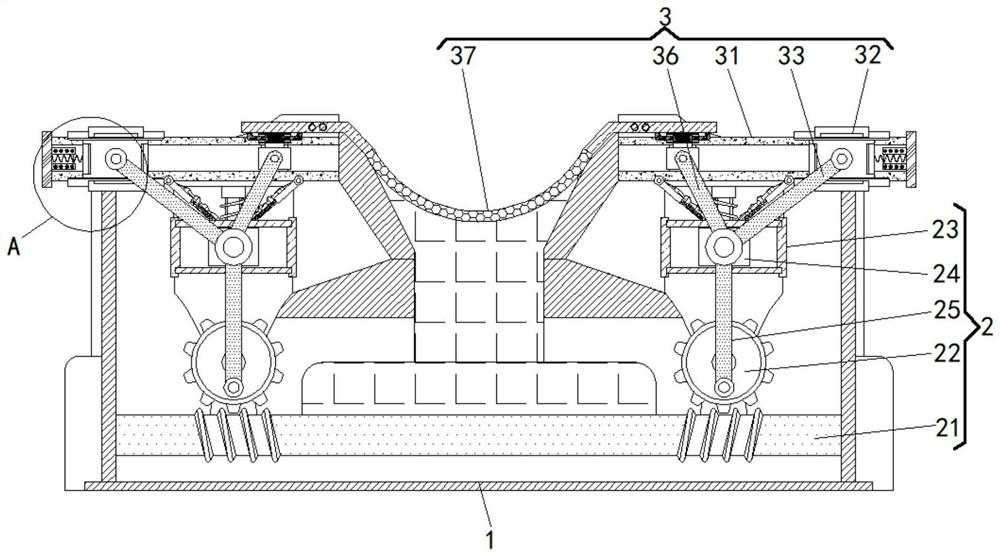

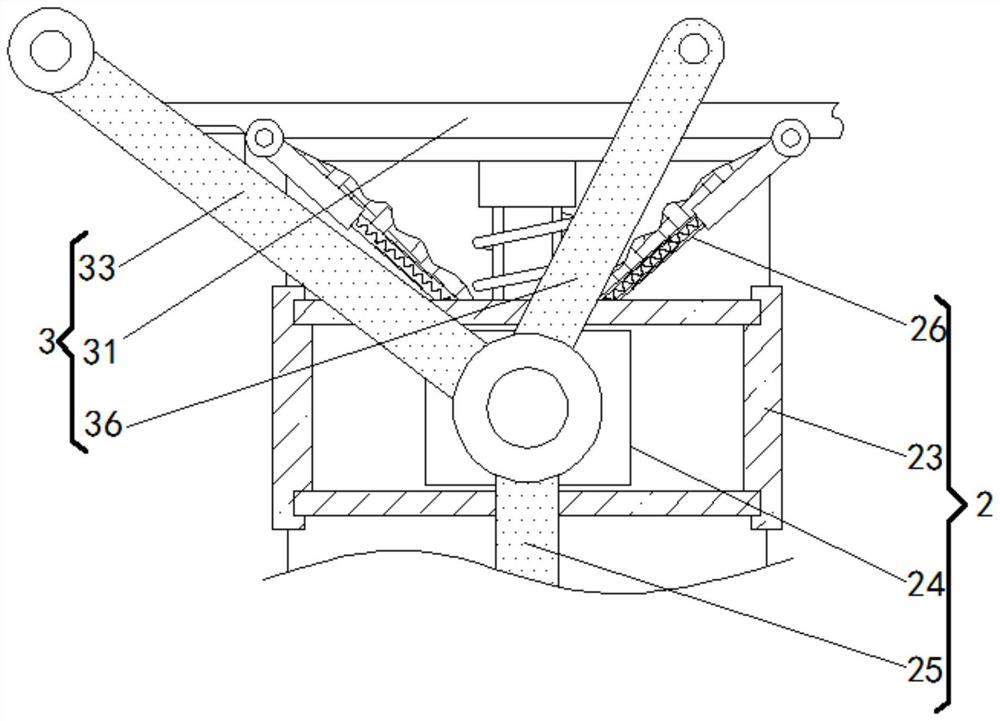

[0022] see figure 1 and 2 , a kind of impurity removal equipment for the main ingredient of stewed meat in sauce, comprising a housing 1, a flushing mechanism 2 is movably connected to the left and right sides of the inner cavity of the housing 1, and a screening mechanism 3 is movably connected to the top of the housing 1 The flushing mechanism 2 includes a worm 21, a rotating gear 22, a protective frame 23, a slider 24, a pole 25, and a telescopic rod 26. The bottom of the inner cavity of the housing 1 is connected to the worm 21 in rotation, and the worm 21 at the bottom of the inner cavity of the housing 1 The upper end of the upper end of the housing 1 is rotatably connected with a symmetrical rotating gear 22, and a protective frame 23 is slidably connected above the inner cavity of the housing 1 rotating gear 22, and the inner cavity of the protective frame 23 is slidably connected with a slider 24, between the slider 24 and the rotating gear 22. A strut 25 is movably ...

Embodiment 2

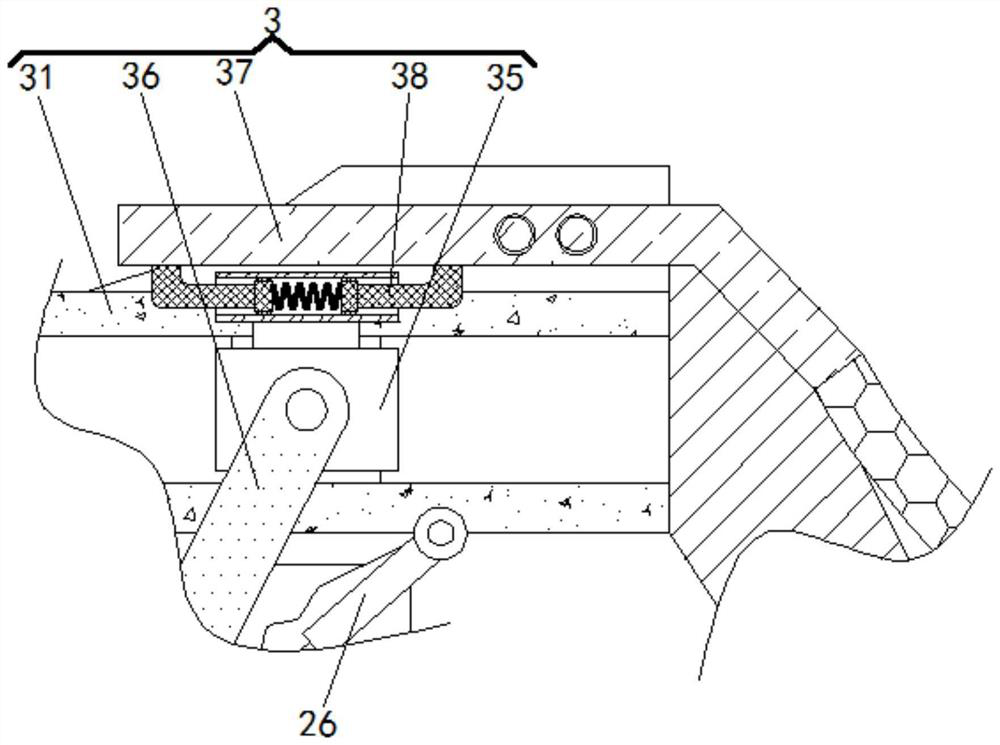

[0024] see Figure 1-4 , a kind of impurity removal equipment for the main ingredient of stewed meat in sauce, comprising a housing 1, a flushing mechanism 2 is movably connected to the left and right sides of the inner cavity of the housing 1, and a screening mechanism 3 is movably connected to the top of the housing 1 The screening mechanism 3 includes a movable frame 31, an elastic magnetic block 32, a connecting rod 33, a winding ring 34, a movable block 35, a push rod 36, a filter plate 37, a vibrating rod 38, and the number of the movable frame 31 is designed to be two and One end of the side wall away from the filter plate 37 is fixedly connected with an eddy current plate, so that when the winding ring 34 is supplied with alternating current, the induced electromotive force caused by the rapidly changing magnetic field can cause eddy current heating on the eddy current plate, and the movable frame 31 The inner cavity is slidably connected with an elastic magnetic block...

Embodiment 3

[0026] see Figure 1-4 , a kind of impurity removal equipment used for main ingredients of stewed meat in sauce, comprising a housing 1, the left side and the right side of the inner cavity of the housing 1 are movably connected with a flushing mechanism 2, and the flushing mechanism 2 includes a worm 21, a rotating gear 22, a protective Frame 23, slider 24, pole 25, telescopic rod 26, the bottom of the inner cavity of the housing 1 is rotatably connected with a worm 21, and the upper end of the worm 21 at the bottom of the inner cavity of the housing 1 is rotatably connected with a symmetrical rotating gear 22. The top of the inner cavity rotating gear 22 of 1 is slidably connected with a protective frame 23, and the inner cavity of the protective frame 23 is slidably connected with a slider 24, and a strut 25 is movably connected between the slider 24 and the rotating gear 22, and the upper end of the protective frame 23 The movable hinge has a symmetrical telescopic rod 26,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com