Extrusion granulator capable of rapidly changing die

A granulator, fast technology, applied in the direction of mold extrusion granulation, solid separation, filtration, etc., to achieve the effect of shortening the mold change time and improving the continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

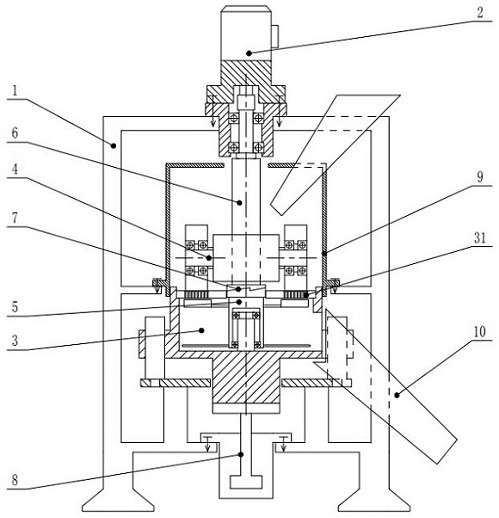

[0032] as attached figure 1 As shown, a kind of quick die-changing extrusion granulator according to Embodiment 1 of the present invention is mainly composed of a frame 1, a reduction motor 2, a die device 3, a pressure roller device 4, a die half shaft 5, and a pressure roller half shaft 6. Main shaft clutch 7, granulation top pressure device 8, extruding bin cover 9 and discharge chute 10; the compression molding device 3 is connected and installed on the frame 1; the compression molding half shaft 5 is connected to Installed in the press mold device 3, the press roller half shaft 6 is installed in the press roller device 4, and the main shaft clutch 7 is respectively connected and installed above the press die half shaft 5 and the press roller The bottom of the half shaft 6; the pressure roller device 4 is connected and installed above the die device 3 through the main shaft clutch 7; the granulation pressing device 8 is connected to the machine below the die device 3 on t...

Embodiment 2

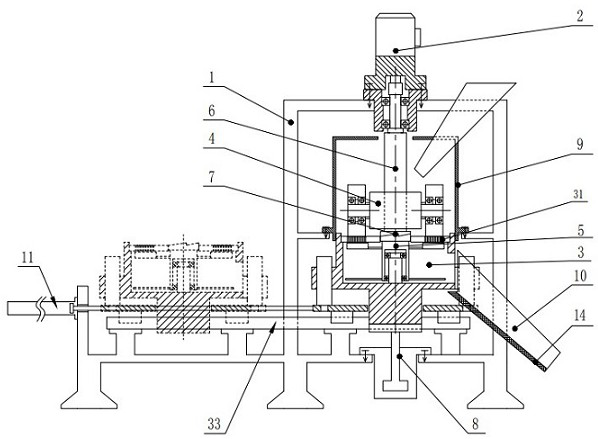

[0035] see figure 2 As shown, the quick die change extrusion granulator of the second embodiment of the present invention is similar to the first embodiment, the only difference is:

[0036] In order to increase the operating space for changing the die 31, facilitate the operation, and make it easier to replace the die 31, a die change push device 11 is provided; the die change push device 11 is connected and installed under the frame 1 Between the frame 1 and the die device 3, when the die 31 needs to be replaced, the granulation pressing device 8 retracts, and the half shaft 5 of the die and the pressure roller The half shaft 6 is separated vertically at the main shaft clutch 7, and the die changing push device 11 retracts to push the die die device 3 away from the pressure roller device 4 along the sliding track 33 below it. Below, maintenance operators or manipulators can easily and conveniently take and install the die 31 without hindrance. The said mold changing pushi...

Embodiment 3

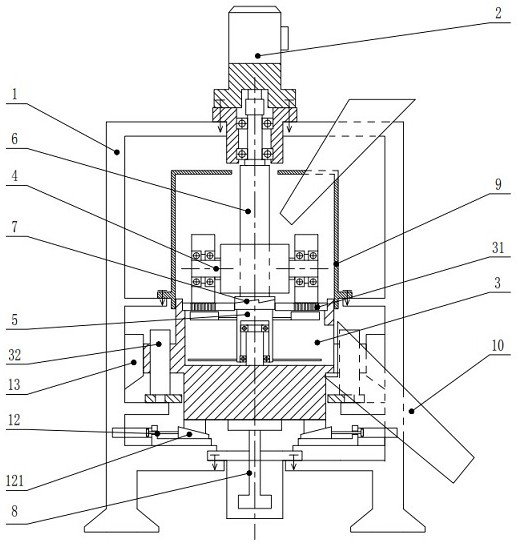

[0039] see image 3 As shown, the quick die change extrusion granulator of the third embodiment of the present invention is similar to the first embodiment, the only difference is:

[0040] In order to realize that the driving mechanism of the granulation pressing device 8 can be closed when the equipment is running, or the driving force of the granulation pressing device 8 can be reduced to achieve a more energy-saving effect, an auxiliary device 12 for increasing the pressing is provided; The pressing auxiliary device 12 is connected and installed between the press molding device 3 and the lower side of the frame 1 . When the equipment is in operation, after the granulation pressing device 8 lifts up the molding device 3, the pressing pad 121 of the auxiliary pressing device 12 is pushed into the bottom of the molding device 3 and Between the frame 1, all or part of the gravity of the die device 3 and the pressure of the press roller device 4 are directly transmitted to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com