A method for sulfonated alkali lignin-based polyvinyl formal sponge for adsorbing antibiotics in sewage

A polyvinyl formal, lignin-based technology, applied in adsorption water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of complex reaction process, large wood consumption, long synthesis time, etc. The preparation method and operation process are simple, the adsorption effect is improved, and the synthesis time is short.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A kind of preparation method of lignin-based polyvinyl formal sponge adsorbent

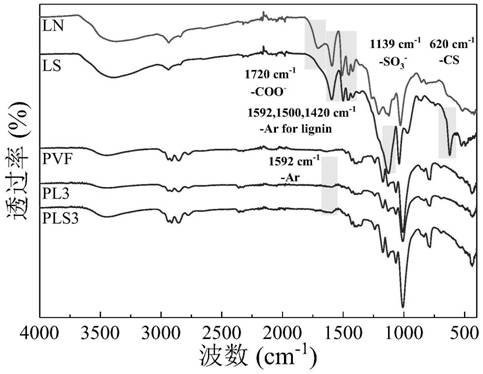

[0050] (1) Alkali lignin (LN) was obtained from papermaking wastewater by dissolving 10 g of alkali lignin in 50 mL of a 3.0 wt% NaOH aqueous solution. The mixture was stirred at 70°C for 30 minutes so that basification occurred. 3 ml of formaldehyde was added to the mixture and stirred for 1 hour, then 2 g of sodium sulfite was added at 95°C and stirred for 3 hours. The product sulfonated alkali lignin was precipitated in ethanol and dried.

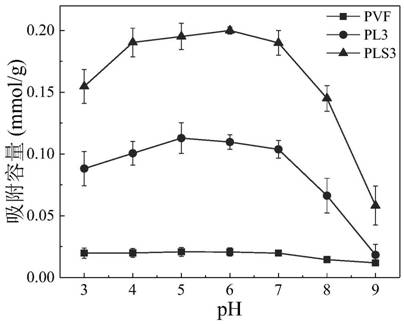

[0051] (2) 0.4 g of alkali lignin or 0.4 g of sulfonated alkali lignin and 4 g of polyvinyl alcohol were dissolved together in 36 ml of water at 95°C, respectively. Add 4g of formaldehyde, 10g (50wt%) sulfuric acid and 2.25g of Triton X-100 to 30g of the mixed solution, and stir at a high speed of 1000 rpm for 10 minutes, then pour the mixed solution into a mold, at 50°C Sponge samples were obtained by drying for 3 hours. Then, the sponge is washe...

Embodiment 2

[0053] A kind of preparation method of lignin-based polyvinyl formal sponge adsorbent

[0054] (1) Alkali lignin (LN) was obtained from papermaking wastewater by dissolving 10 g of alkali lignin in 50 mL of a 3.0 wt% NaOH aqueous solution. The mixture was stirred at 70°C for 30 minutes so that basification occurred. 3 ml of formaldehyde was added to the mixture and stirred for 1 hour, then 2 g of sodium sulfite was added at 95°C and stirred for 3 hours. The product sulfonated alkali lignin was precipitated in ethanol and dried.

[0055] (2) 1.2 g of alkali lignin or 1.2 g of sulfonated alkali lignin and 4 g of polyvinyl alcohol were dissolved together in 36 ml of water at 95°C, respectively. Add 4g of formaldehyde, 10g (50wt%) of sulfuric acid and 2.25g of Triton X-100 to 30g of the mixed solution, and stir at a high speed of 1300 rpm for 10 minutes, then pour the mixed solution into a mold, at 55°C Sponge samples were obtained by drying for 3 hours. Then, the sponge is wa...

Embodiment 3

[0060] A kind of preparation method of lignin-based polyvinyl formal sponge adsorbent

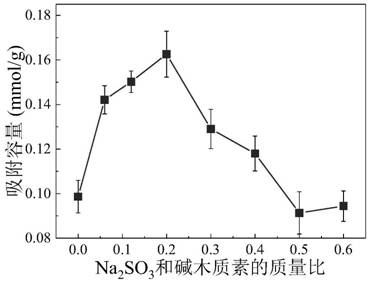

[0061] (1) Alkali lignin (LN) was obtained from papermaking wastewater by dissolving a certain amount of alkali lignin in 50 mL of a 3.0 wt% NaOH aqueous solution. The mixture was stirred at 70°C for 30 minutes so that basification occurred. 3 ml of formaldehyde was added to the mixture and stirred for 1 hour, then a certain amount of sodium sulfite was added at 95°C and stirred for 3 hours. The product sulfonated alkali lignin was precipitated in ethanol and dried.

[0062] (2) 1.2 g of alkali lignin or 1.2 g of sulfonated alkali lignin and 4 g of polyvinyl alcohol were dissolved together in 36 ml of water at 95°C, respectively. Add formaldehyde, (50wt%) sulfuric acid and Triton X-100 to 30 g of the mixed solution, stir at 1300 rpm for 10 minutes, pour the mixed solution into a mold, and dry at 55°C for 3 hours to obtain a sponge sample. The sponge is then washed with water and dried. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com