Sealing element impregnation fixing mechanism and impregnation system

A technology for fixing mechanisms and seals, applied in coatings, devices for coating liquids on the surface, etc., can solve problems such as difficult dipping, low density, and easy bonding of seals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

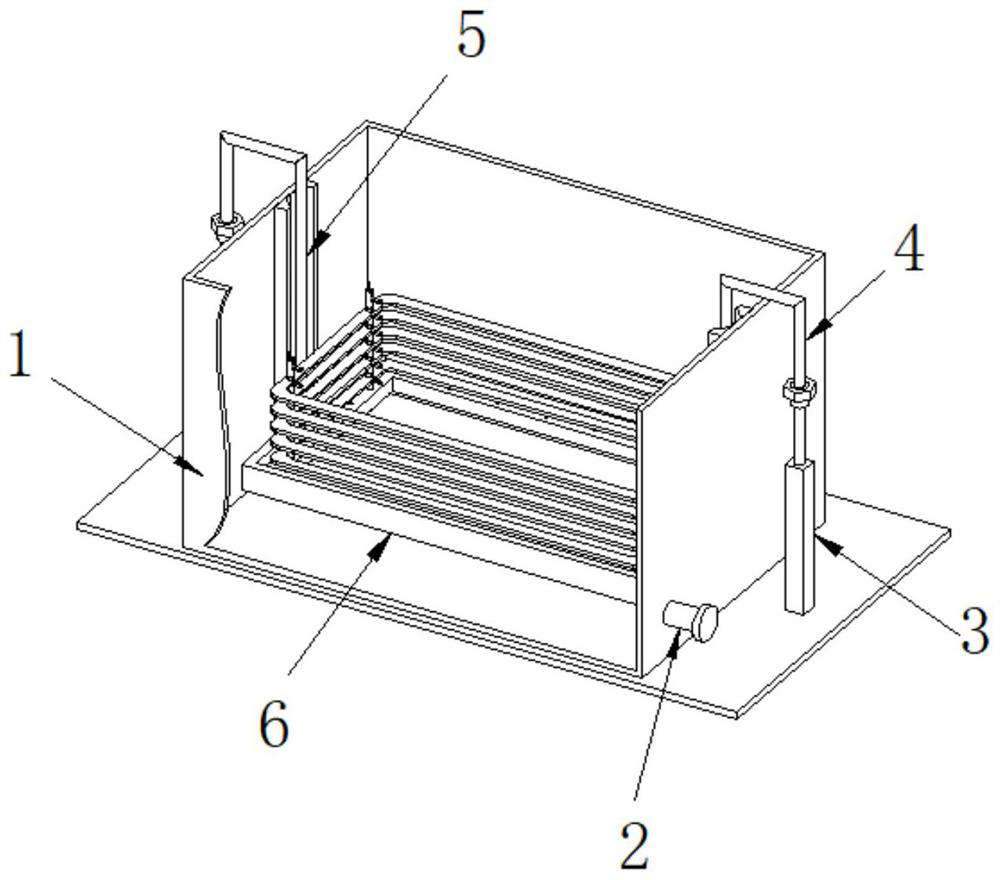

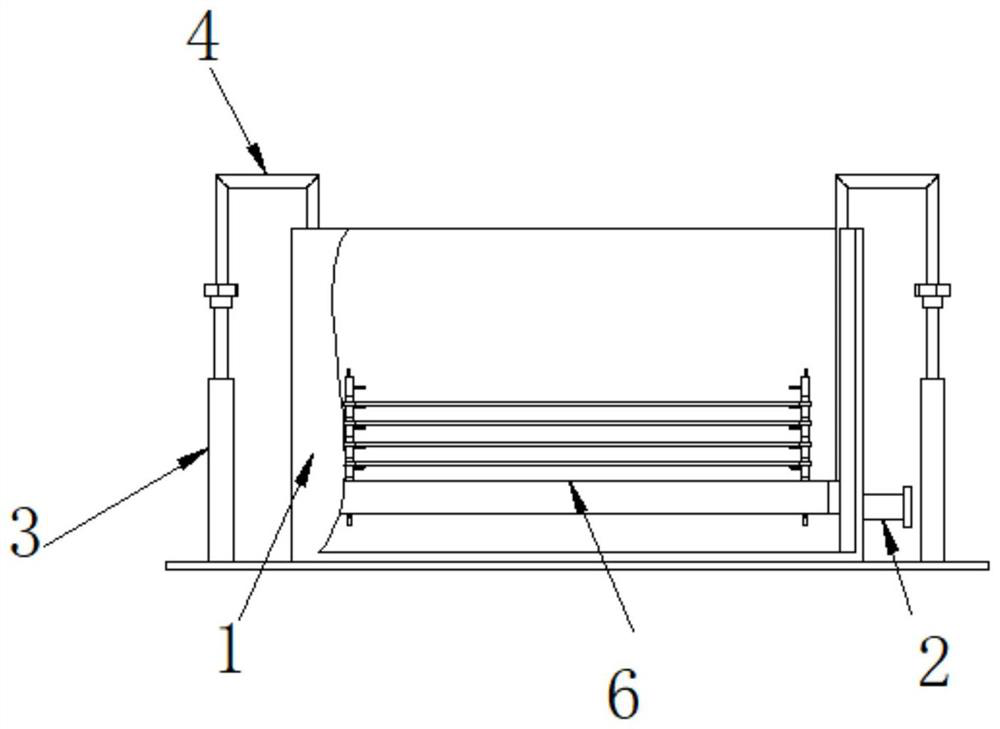

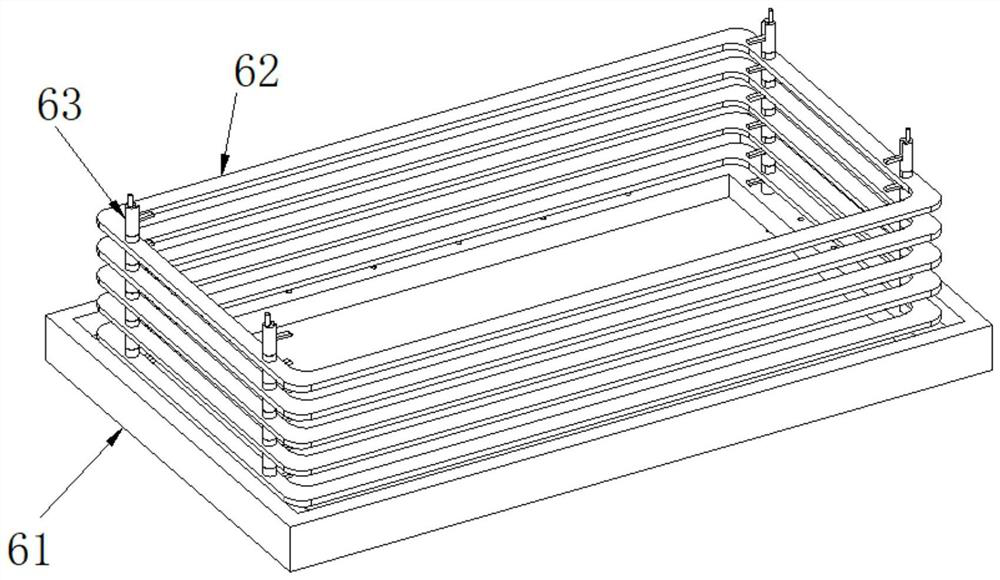

[0028] Such as Figure 1-6 As shown: the present invention provides a sealing member dipping fixing mechanism, the sealing member dipping fixing mechanism includes a base 61 and a plurality of positioning post assemblies arranged on the base 61; the positioning post assembly includes A plurality of positioning posts 63 spliced sequentially from top to bottom; a slot 66 is formed on the surface of the positioning post 63, and a support plate 67 is hinged in the slot 66, so that the support plate 67 can rotate to the Inside the slot 66 ; the positioning column 63 passes through the hole of the seal 62 , so that the seal 62 is located between two adjacent suppor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com