Large-size variable-curvature aluminum alloy wallboard preloading equipment and forming method

An aluminum alloy and preloading technology, which is applied in the field of preloading equipment and forming of large-scale variable curvature aluminum alloy siding, can solve problems such as cracks and breakage of siding ribs, and influence of siding performance, and achieve large forming force, Reliable molding and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] This embodiment provides a method for forming a large-size variable-curvature aluminum alloy panel, which includes the following steps:

[0067] 1. First mill the aluminum alloy wall panel with the size of 5000×3000×6mm into the required shape of the ribbed wall panel, and the milling depth is 2mm;

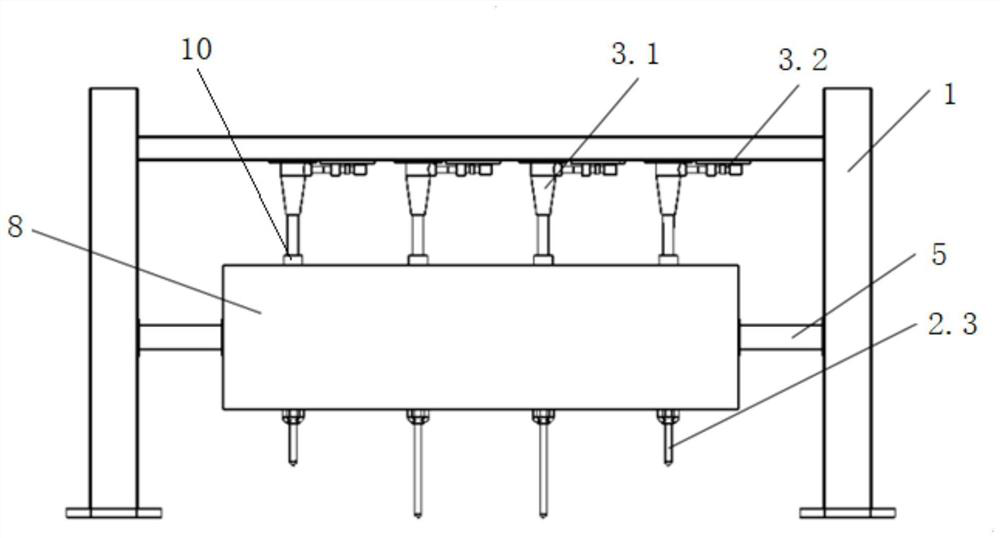

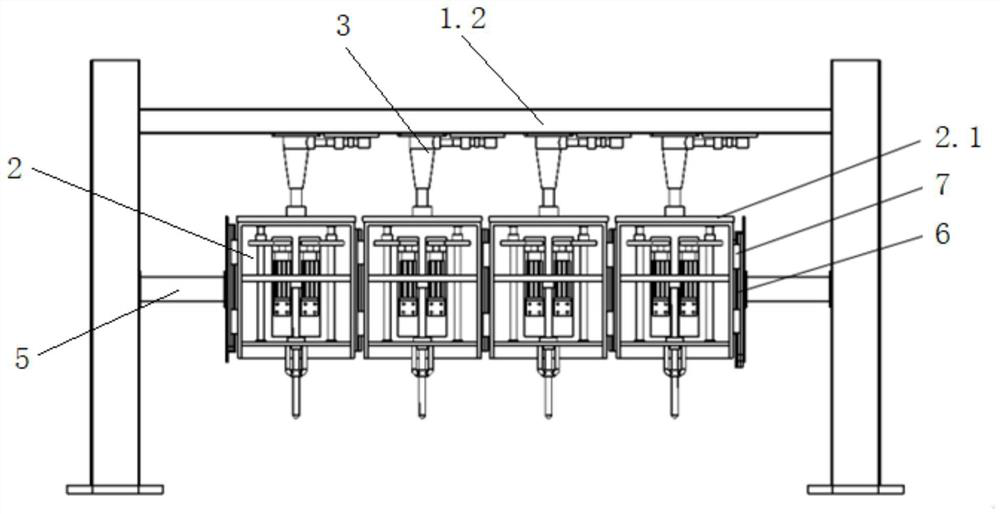

[0068] 2. Lift the mold to the bottom of the gantry with a crane and complete the positioning of the mold. Put the ribbed wallboard after milling into the mold for positioning, set sealant around the mold, and lay air-permeable air on the upper surface of the wallboard. felt, vacuum bag, silicone;

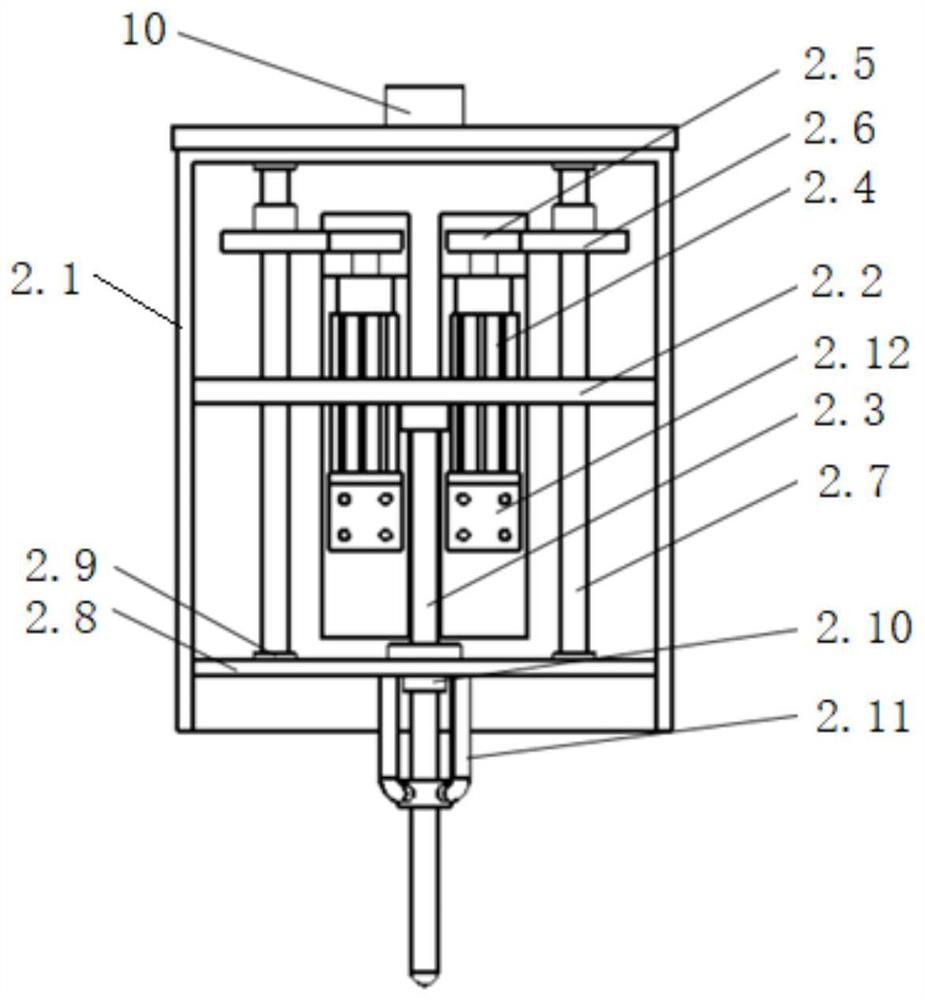

[0069]3. Because the hanging height between the wall plate and the mold is too high, the pushing distance of the push rod of the loading box is limited, so it is necessary to use a jack for part of the pushing; firstly, adjust the jack at the upper end of the loading box so that the push rod 2.3 of each loading box is formed to be in line with the mold The curvature of the surf...

Embodiment 2

[0072] This embodiment provides a method for forming a large-size variable-curvature aluminum alloy panel, which includes the following steps:

[0073] 1. First mill the aluminum alloy wall panel with the size of 4000×2500×5mm into the required shape of the ribbed wall panel, and the milling depth is 2mm;

[0074] 2. Lift the mold to the bottom of the gantry with a crane and complete the positioning of the mold. Put the ribbed wallboard after milling into the mold for positioning, set sealant around the mold, and lay air-permeable air on the upper surface of the wallboard. felt, vacuum bag, silicone;

[0075] 3. The panel forming requirement is a multi-curvature panel with a small curvature. Since the push rod of the loading box meets the maximum hanging height, the push rod on the loading box can be directly used for preloading. Firstly, the motor in each loading box is driven , so that the push rods 2.3 of each loading box form a curvature similar to that of the mold surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com