Spin welding device for preventing middle part of tower crane base section from drooping during welding

A technology of spin welding and base joints, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding efficiency, sagging deformation of base joints, and inconvenient welding, so as to improve welding quality, prevent welding dead ends, The effect of preventing sagging deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

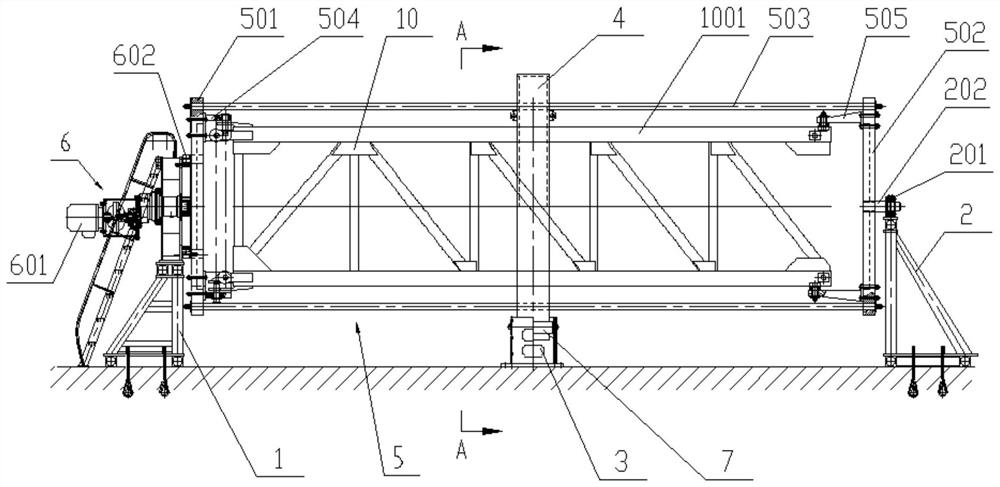

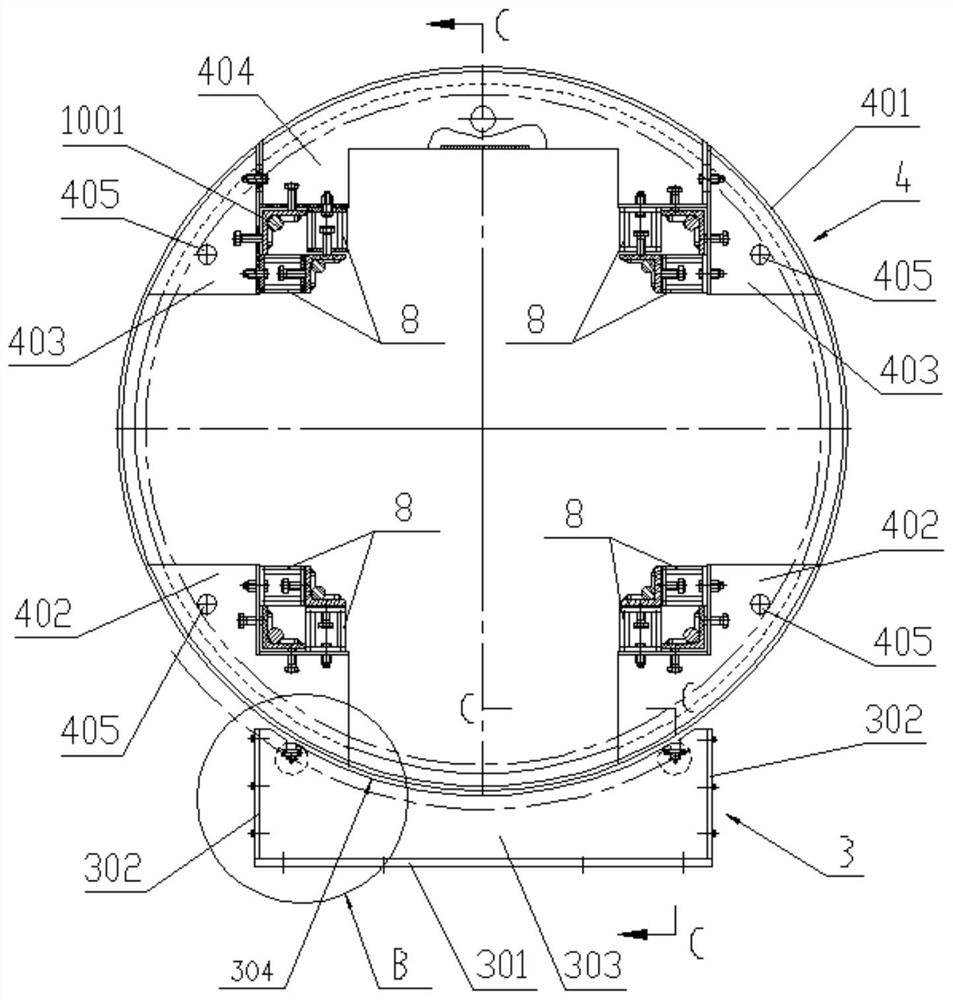

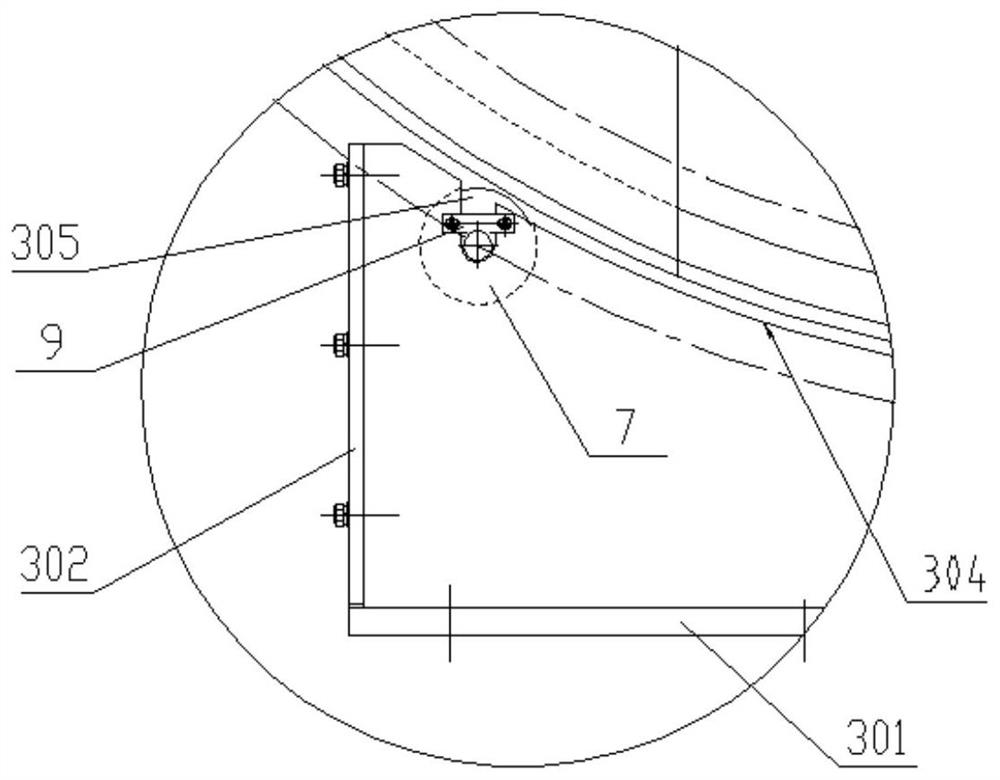

[0026] see Figure 1-Figure 5 , a rotary welding device that prevents the middle part from sagging when the base section of the tower crane is welded. The side is fixed on the ground, and the driving mechanism 6 is fixedly installed on the left support 1. The middle support includes a support seat 3 and a support drum 4. The support seat 3 is fixed on the ground and is located in the middle position between the left support 1 and the right support 2. The support The base 3 is fixedly equipped with two freely rotatable rollers 7, the supporting roller 4 is placed on the roller 7 and the outer circle of the supporting roller 4 is in rolling contact with the roller 7, the rotating frame 5 passes through the supporting roller 4 and It is radially fixed with the support drum 4, and can drive the support drum 4 to rotate simultaneously when the rotating frame 5 rotates. The left end of the rotating frame 5 is fixedly connected with the driving mechanism 6, and the right end is rotat...

Embodiment 2

[0038] This embodiment is basically the same as Embodiment 1, except that the support plate 303 is provided with three waist-shaped grooves 305 for installing the roller 7 along the arc surface 304, such as Image 6 As shown, at the two ends and the bottom of the arc surface 304 respectively, the supporting seat 3 is fixedly equipped with three freely rotatable rollers 7, which further strengthen the bearing capacity of the supporting drum 4 and the base joint 10, and ensure the reliability of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com