Grinding clamp suitable for turbine multi-connected guide vane part assembly

A technology of parts and fixtures, which is applied in the direction of grinding workpiece supports, etc., can solve problems such as easy deformation, and achieve the effects of easy processing, enhanced clamping rigidity, and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

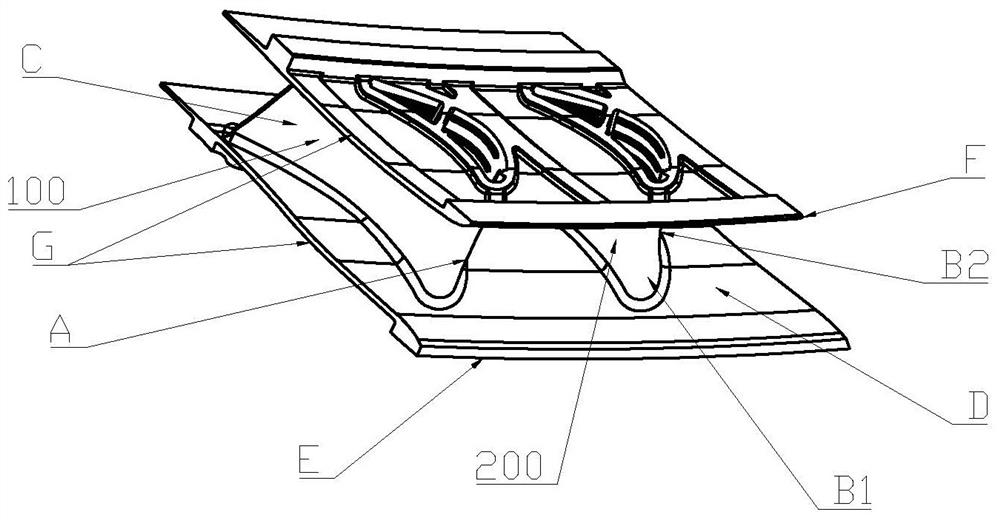

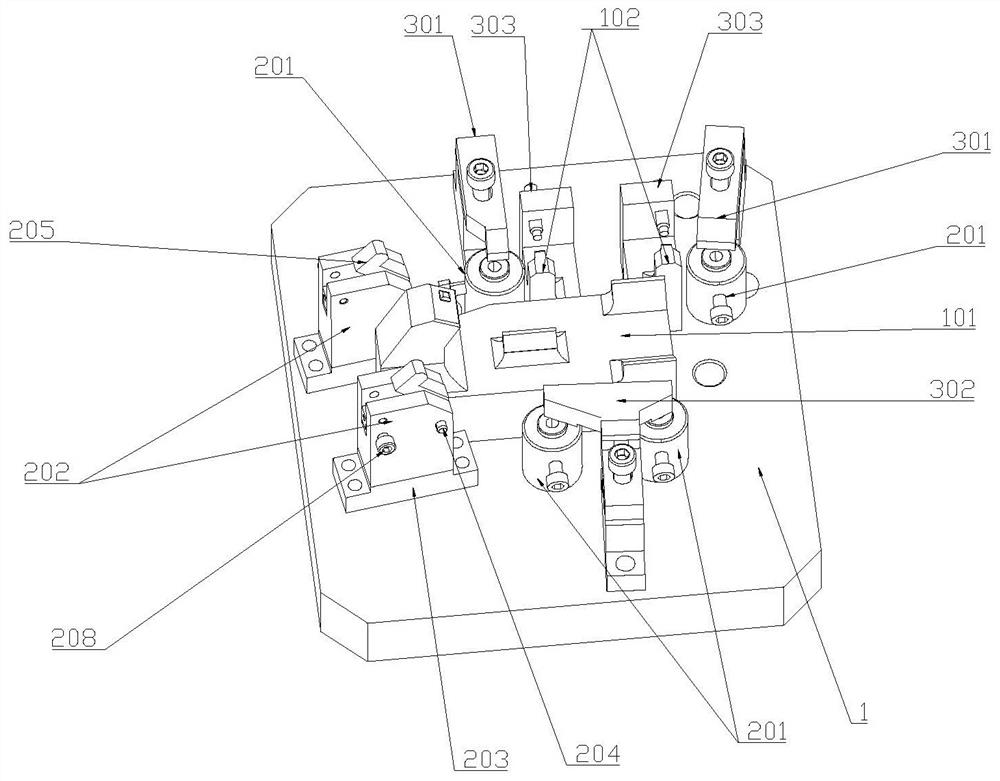

[0026] Such as figure 1 , figure 2 Shown is a grinding jig adapted to the assembly of multiple guide vanes of a turbine, which includes a mounting base plate 1 on which a positioning mechanism, a supporting mechanism and a pressing mechanism are installed.

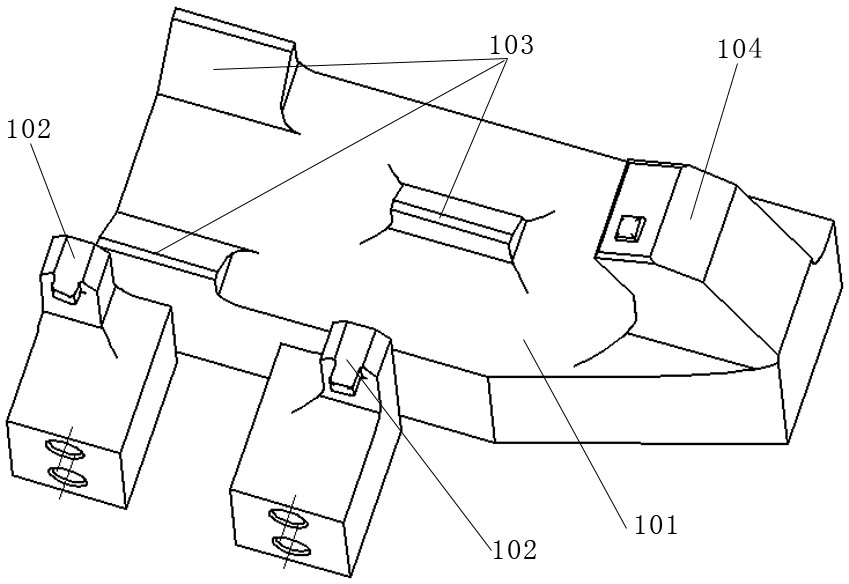

[0027] combine image 3 The positioning mechanism includes a blade positioning block 101 and a blade outer ring flow channel surface fixture positioning block 102. The top of the blade positioning block 101 protrudes upwards to form a positioning boss 103 and a positioning boss 2 104, and the positioning boss 103 is connected with the parts. The position of the gas side is corresponding, the position of the positioning boss 2 104 is corresponding to the position of the inner arc surface C of the part, and the positioning block of the blade outer ring flow channel surface clamp 102 is used to laterally resist the outer ring flow channel surface D of the part from the inner wall of the part.

[0028] Specifically, the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com