Unmanned aerial vehicle purging device for factory steel beam

A technology for unmanned aerial vehicles and steel beams, which is applied to cleaning methods using gas flow, rotorcraft, motor vehicles, etc., can solve the problems of high cost, high risk factor of manual cleaning of steel beams, low efficiency, etc. Reduce labor costs, high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

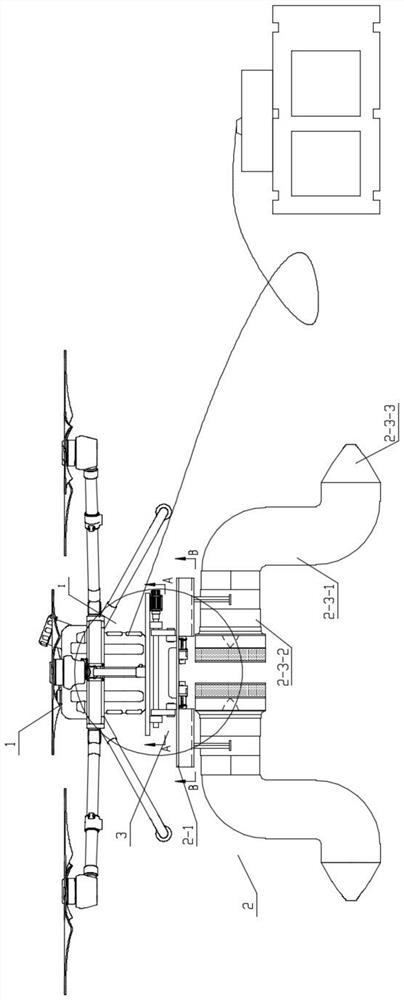

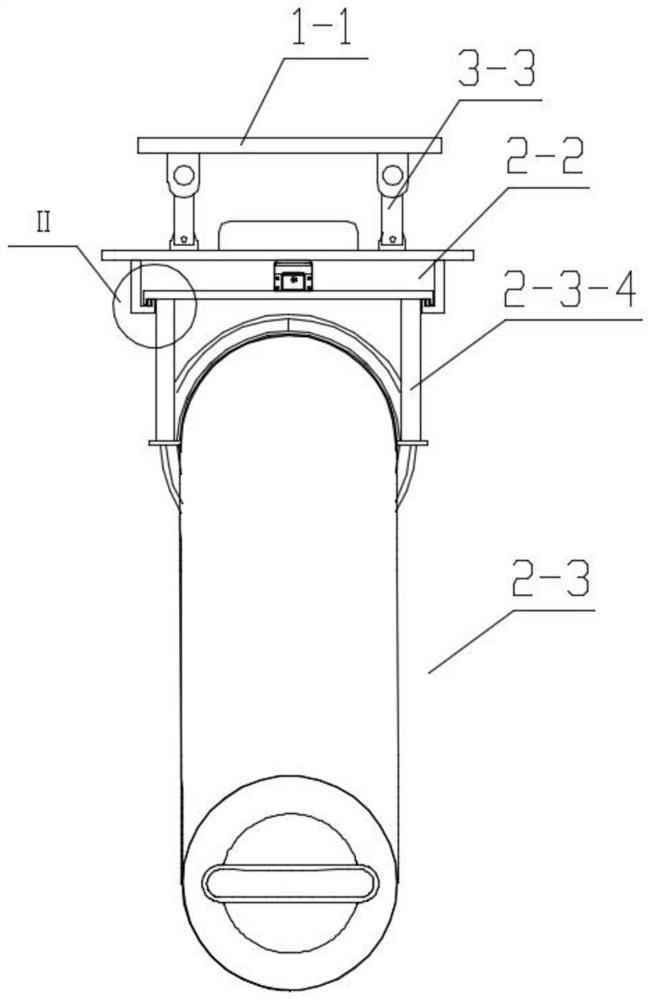

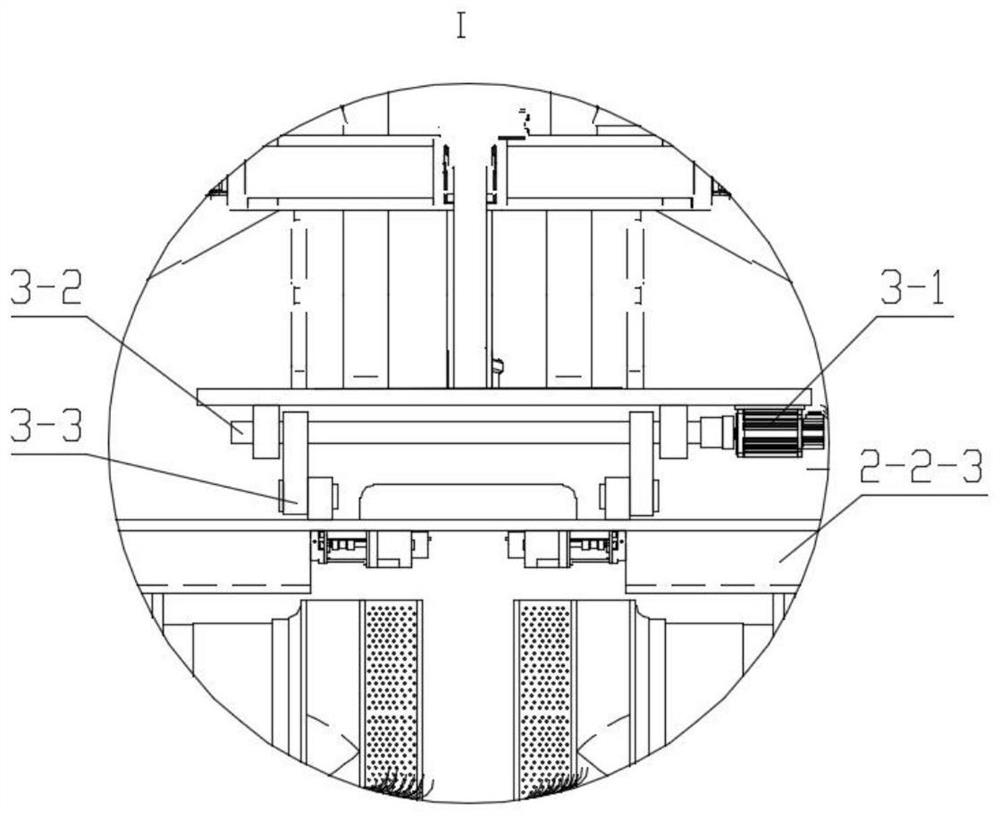

[0042] Such as Figures 1 to 12 Shown is an unmanned aerial vehicle purging device for steel beams in factories, which includes an unmanned aerial vehicle 1, a purging device 2 located at the bottom of the unmanned aerial vehicle 1, a rotating drive device 3, a monitoring system and a control system, The rotary drive device 3 drives the purge device 2 to rotate; the rotary drive device 3 can be set to rotate the purge device 2 according to the actual purge position height, etc., to adapt to the actual height, and avoid the relatively small upper space of the purge device 2. The air outlet cannot reach the top surface of the steel beam.

[0043]The purging device 2 includes a mounting plate 2-1, two sets of conveying devices 2-2 and two sets of purging mechanisms 2-3, and the two sets of conveying devices 2-2 are respectively arranged on both ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com