Aerogel back-end production line

An airgel and production line technology, applied in the direction of load suspension components, load blocks, cranes, etc., can solve the problems of low work efficiency and reduce the production efficiency of airgel, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

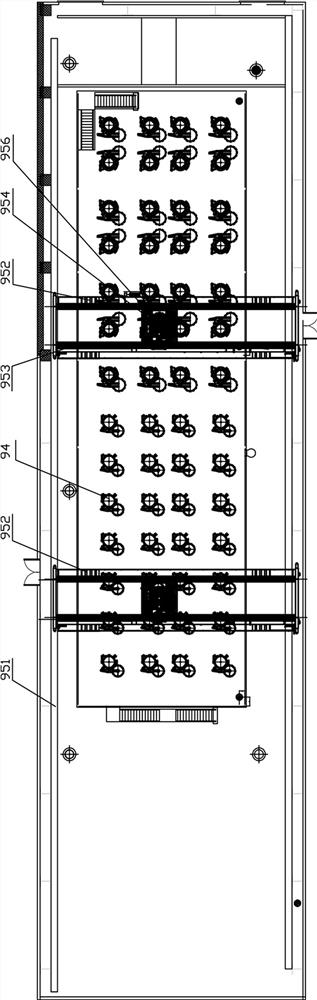

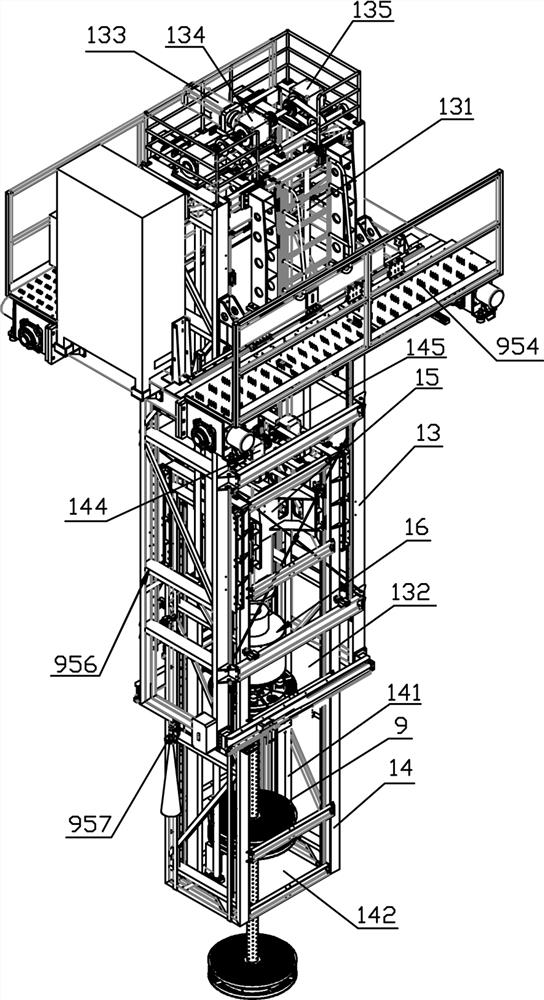

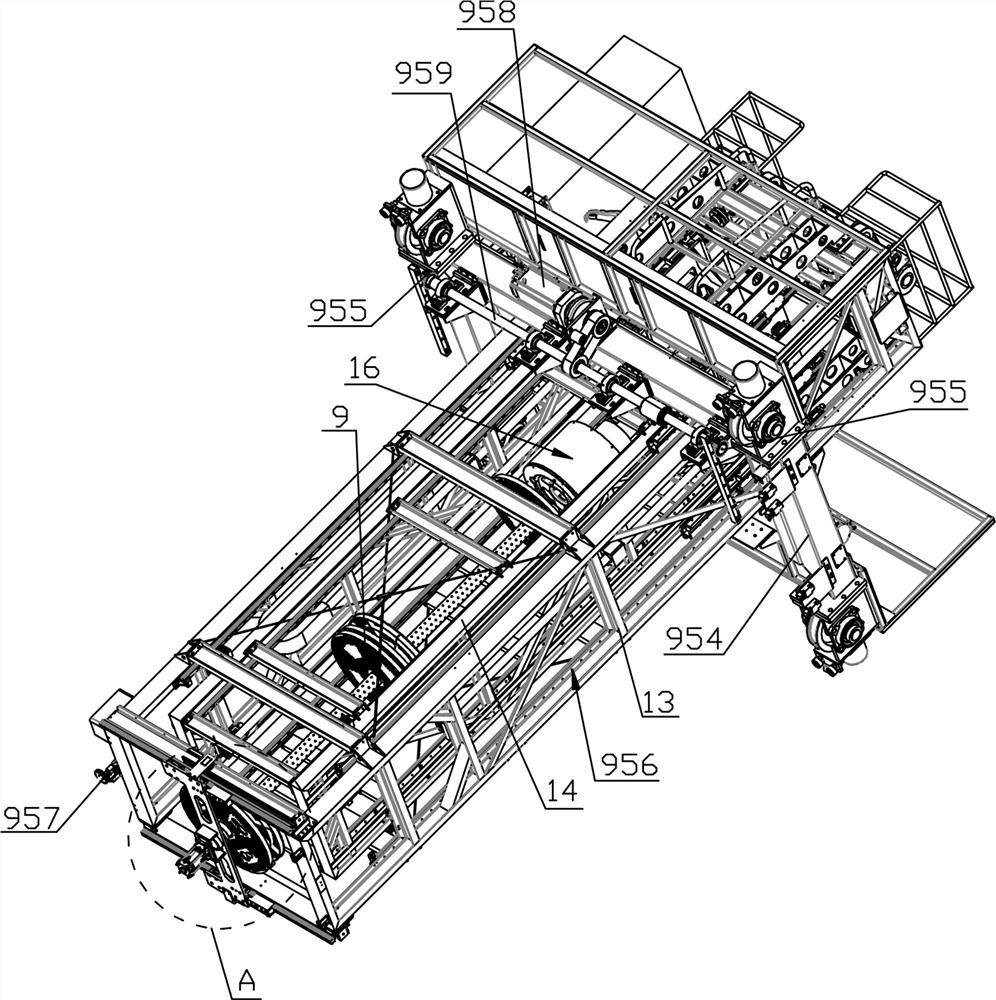

[0037] Such as figure 1 , figure 2 , image 3 As shown, the airgel downstream production line includes: several process tanks 94 placed in the working area for processing airgel substrates and a row crane mechanism for lifting the airgel substrate loading tooling, row crane The mechanism can hoist the airgel substrate loading tooling into the process tank 94 or hang out the airgel substrate loading tooling from the process tank 94. The structure of the lifting mechanism includes: two X-direction rails 951, at least one bridge crane Two X-direction rails 951 are erected on the left and right sides of the working area along the front and rear direction respectively. The structure of the bridge lifting device includes: bridge frame 952, which spans above the working area and can move forward and backward through rollers. Installed on two...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap