High-speed precise gear transmission device

A gear transmission and precision technology, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of inconvenience, inconvenient cooperation with reversing adjustment, and inability to realize power switching operations, etc., to achieve placement and connection, and convenient cooperation The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

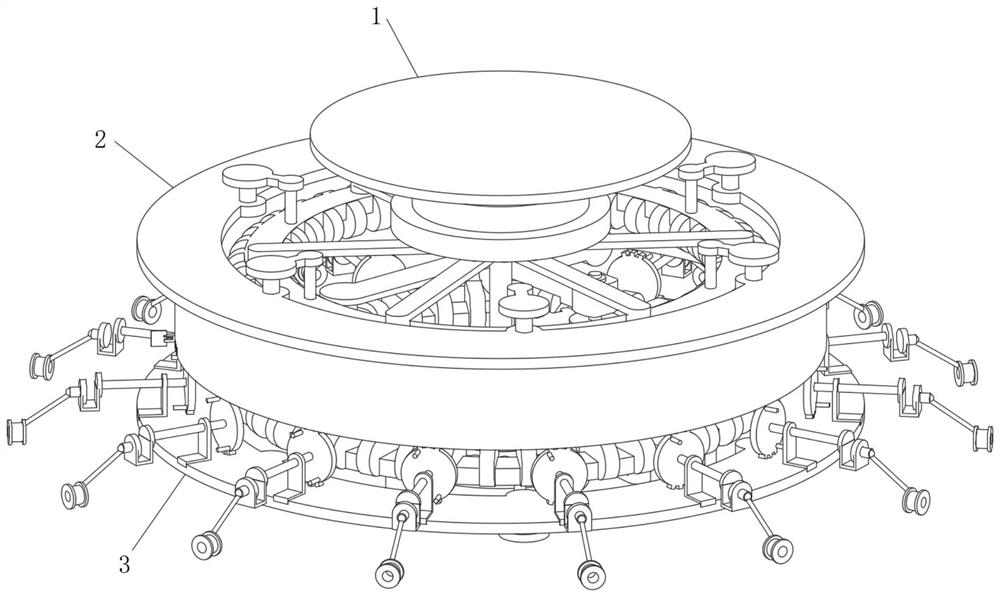

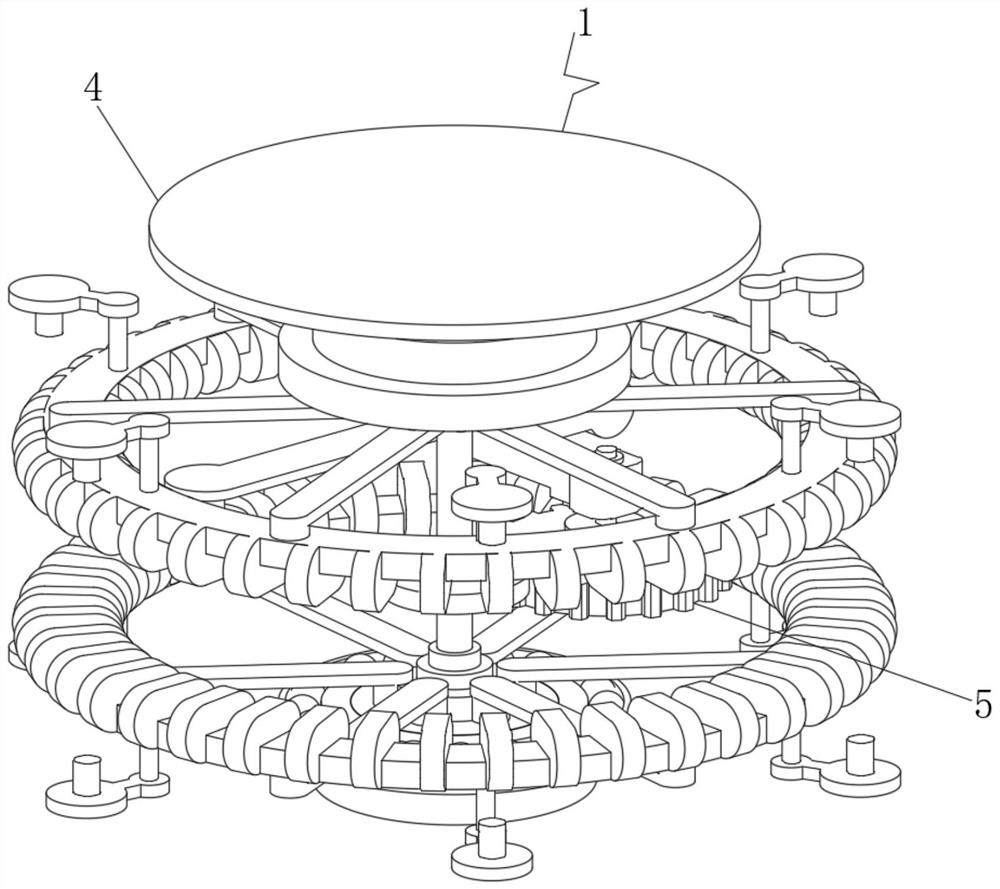

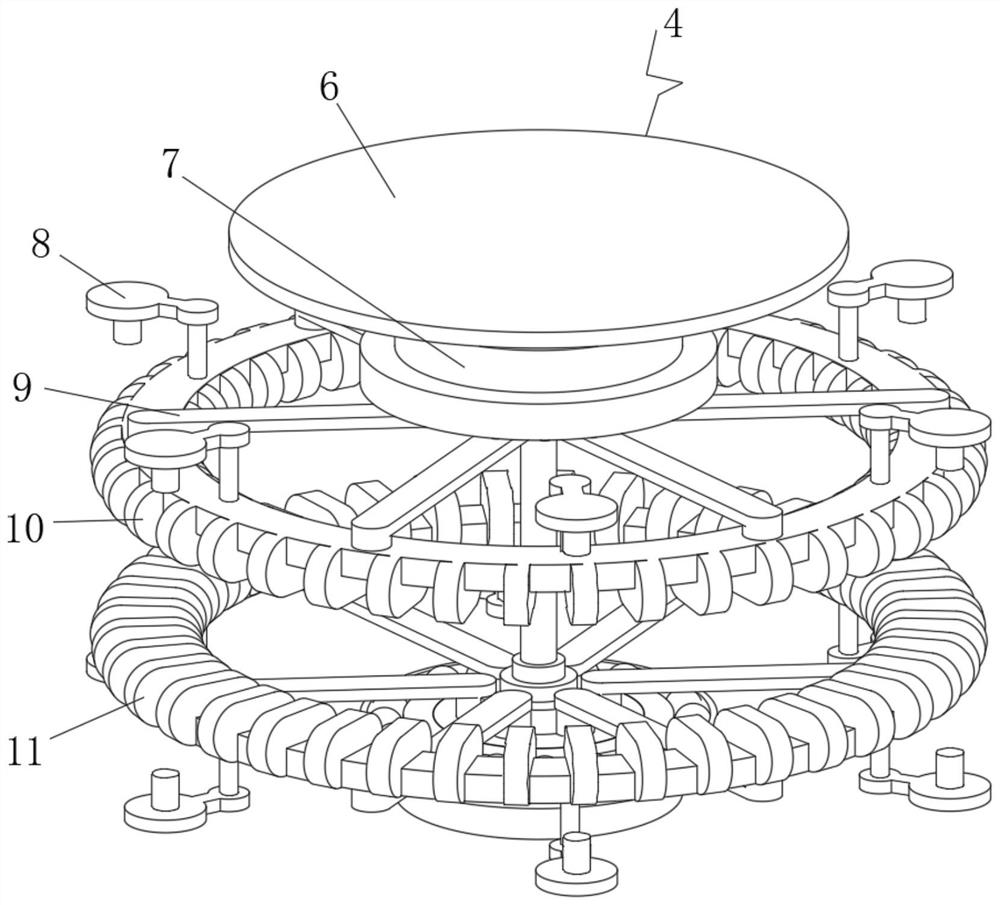

[0032] see Figure 1-7 , the present invention provides a technical solution: a high-speed precision gear transmission device, including a gear matching device 1, the side end position of the gear matching device 1 is fixedly connected with an adjustment device 2, and the bottom end position of the adjustment device 2 is connected with an external machining Device 3, by installing the gear matching device 1, the inner end of the gear matching device 1 is composed of a conductive part 4 and a steering part 5, wherein the conductive part 4 is used for supporting connection, which can realize the power transmission function, thereby driving the externally connected objects Carry out the rotation drive, and the setting of the steering part 5 adopts an adjustable setting, which can be regulated according to the demand, so as to realize the rotation control work of the first rotating toothed disc 10 and the second rotating toothed disc 11, which is convenient for the adjustment of th...

Embodiment 2

[0043] On the basis of Example 1, such as Figure 8 As shown, the bottom position of the external processing device 3 is fixedly sleeved with a holding plate 36 , the side end of the holding plate 36 is fixedly connected with a blocking plate 35 , and the upper end of the blocking plate 35 is provided with a second notch 34 .

[0044] Through the setting of the second notch 34, the barrier plate 35 and the holding plate 36, the placement of the processing solution can be realized, the production work with the external processing device 3 can be realized, and the overall production function can be realized, and through the second notch 34, It can facilitate the feeding work, and can cooperate with the external processing device 3 at the same time to realize the placement and connection of the upper end of the connecting seat cover 31 and the subsequent dismantling work.

[0045] Working principle: When work is required, the user sets the gear matching device 1, the adjustment d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com