Liquid gas inflating and subpackaging equipment

A liquid gas and sub-packaging technology, which is applied to equipment loaded into pressure vessels, gas/liquid distribution and storage, mechanical equipment, etc. The problem of high damage probability, to achieve the effect of improving production efficiency, convenient operation and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

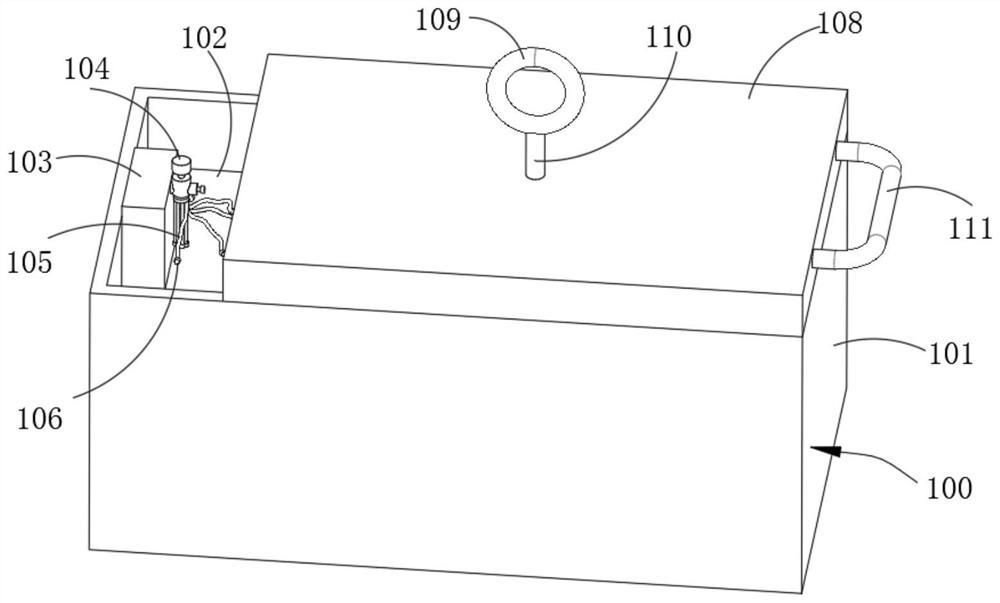

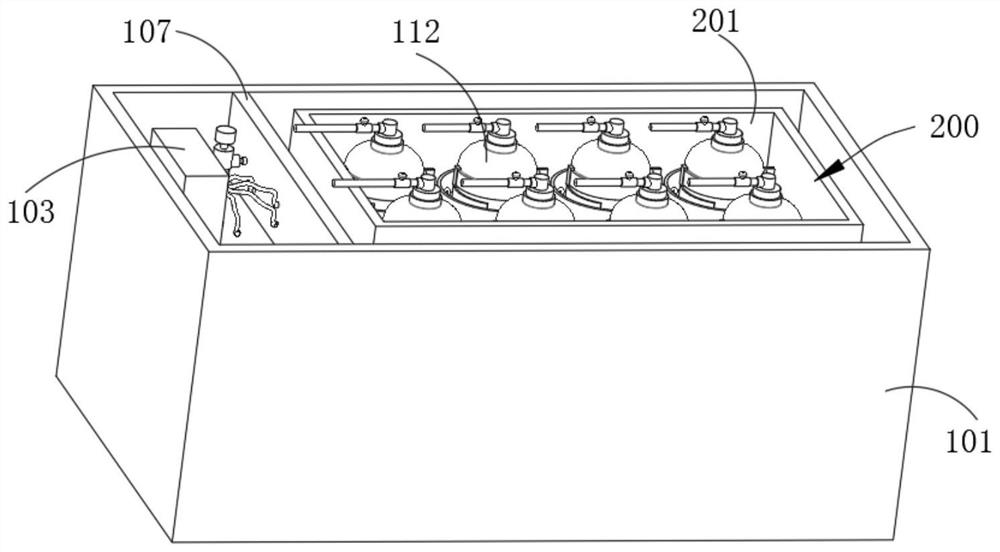

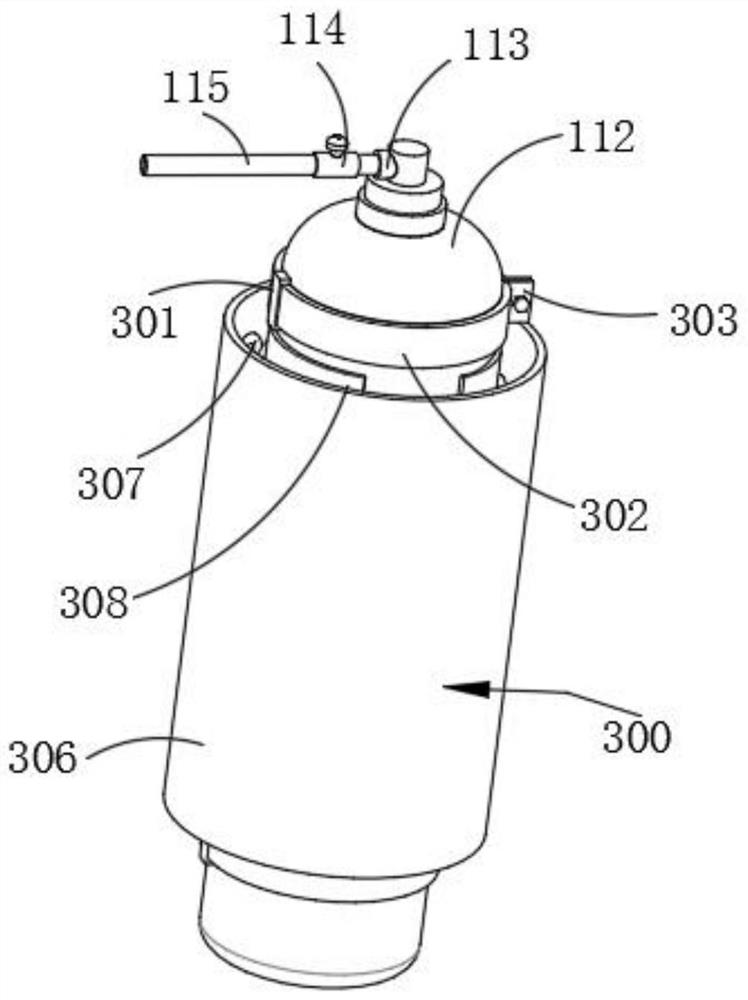

[0033] see Figure 1-6 , the present invention provides a technical solution: a liquid gas inflatable and sub-packaging equipment, including a safety inflatable mechanism 100, the safety inflatable mechanism 100 includes a sub-packaging box 101, and a partition 107 is fixedly connected in the sub-packaging box 101. A sealing cover 108 is installed on the top, an inflatable device 103 is fixedly connected to one side of the partition 107, a plurality of connecting pipes 105 are fixedly connected to the output end of the inflatable device 103, and an inflatable solenoid valve 104 is fixedly connected to one end of the plurality of connecting pipes 105. The other end of each connecting pipe 105 is fixedly connected with an inflation joint 106, and inflation can only be started by opening the inflation solenoid valve 104 externally, which improves the safety during the gas distribution process;

[0034] Anti-dumping mechanism 200, the anti-dumping mechanism 200 includes an anti-du...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com