Processing method for transparent area of glass substrate coated with AG layer

A glass substrate and transparent area technology is applied in the processing field of the transparent area of the glass substrate, which can solve the problems of easy occurrence of defective products, affecting the appearance of products, and difficulty in controlling the grinding process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

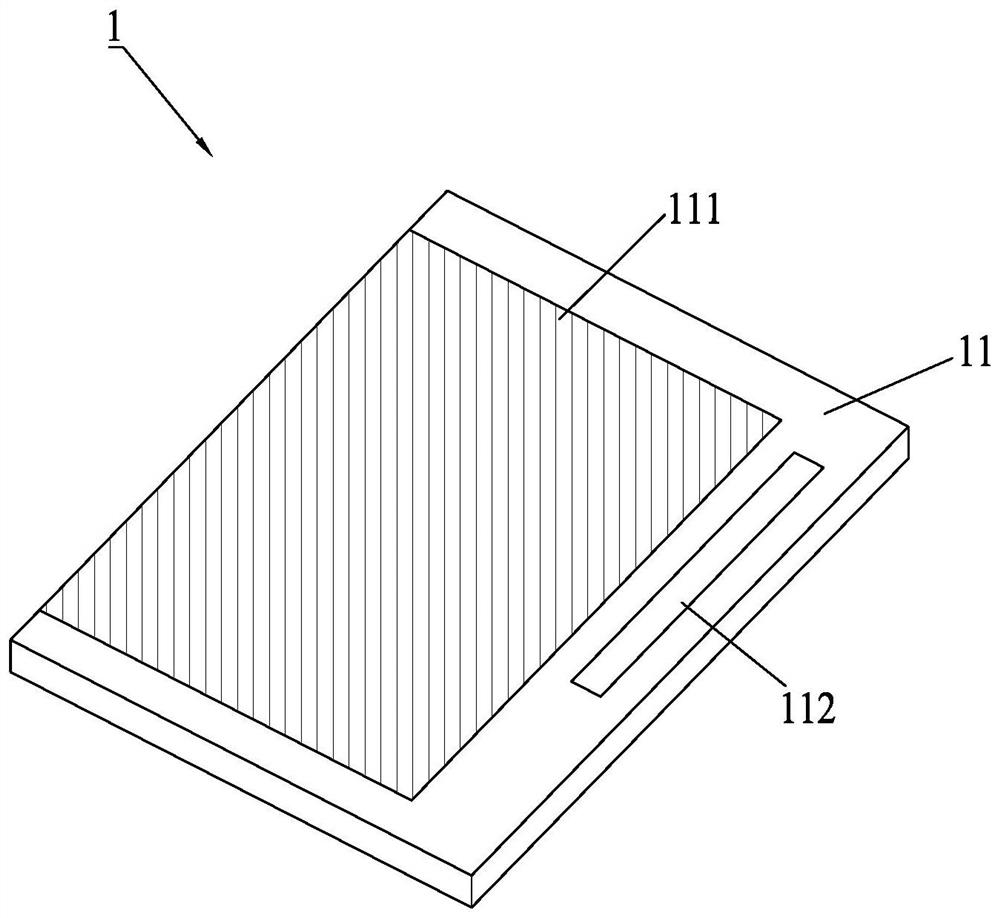

[0016] Such as figure 1 As shown, the front surface 11 of the glass substrate 1 is provided with a touch screen 111 and a transparent area 112;

[0017] A processing method for a transparent region of a glass substrate coated with an AG layer, characterized in that it comprises the following processes:

[0018] Step 1: Printing a circuit on the front surface 11 of the glass substrate 1 by screen printing, and coating ink on the transparent area 112 of the glass substrate 1, and the ink is a curing agent with a weight content of 1-3%;

[0019] Step 2: Baking the ink to make it dry; the temperature of the baking ink is 130-150°C, and the baking time is 5-15 minutes;

[0020] Step 3: Coating an AG layer on the entire front surface 11 of the glass substrate 1:

[0021] Step 4: Clean the front surface 11 of the glass substrate 1 again by ultras...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com