Rapid thickener

A thickener, fast technology, applied in separation methods, settling tanks, sustainable waste treatment, etc., can solve the problems of long discharge time, complex rake structure, large diameter of the thickener tank, etc., to improve dehydration speed and The effect of mass concentration, increasing the effective storage volume, and shortening the preparation time for discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

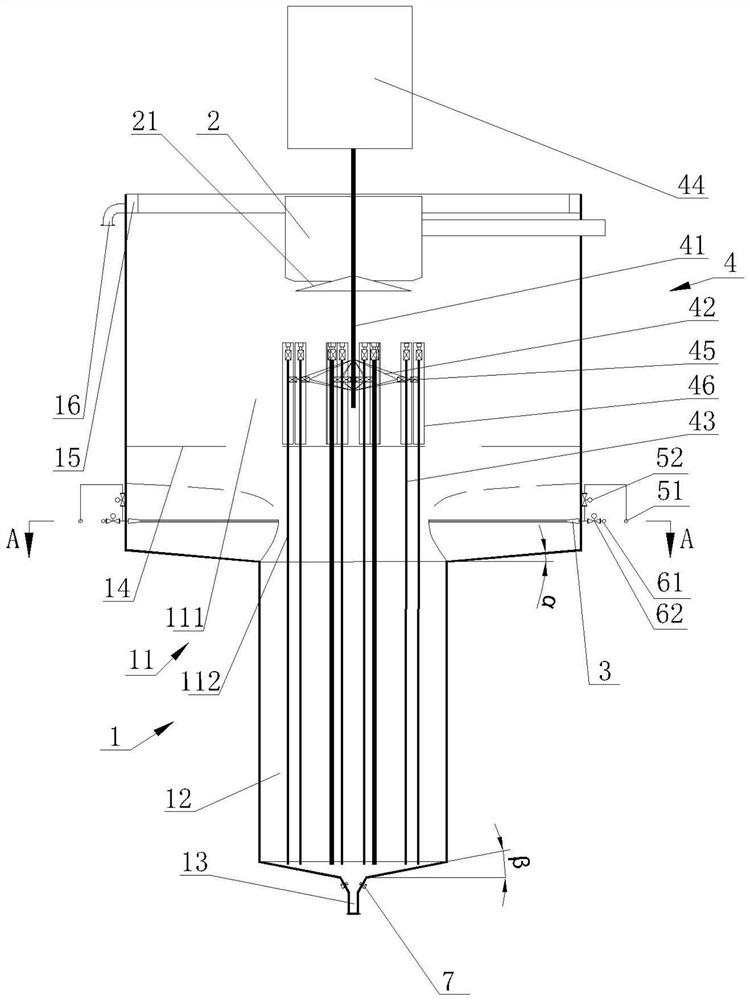

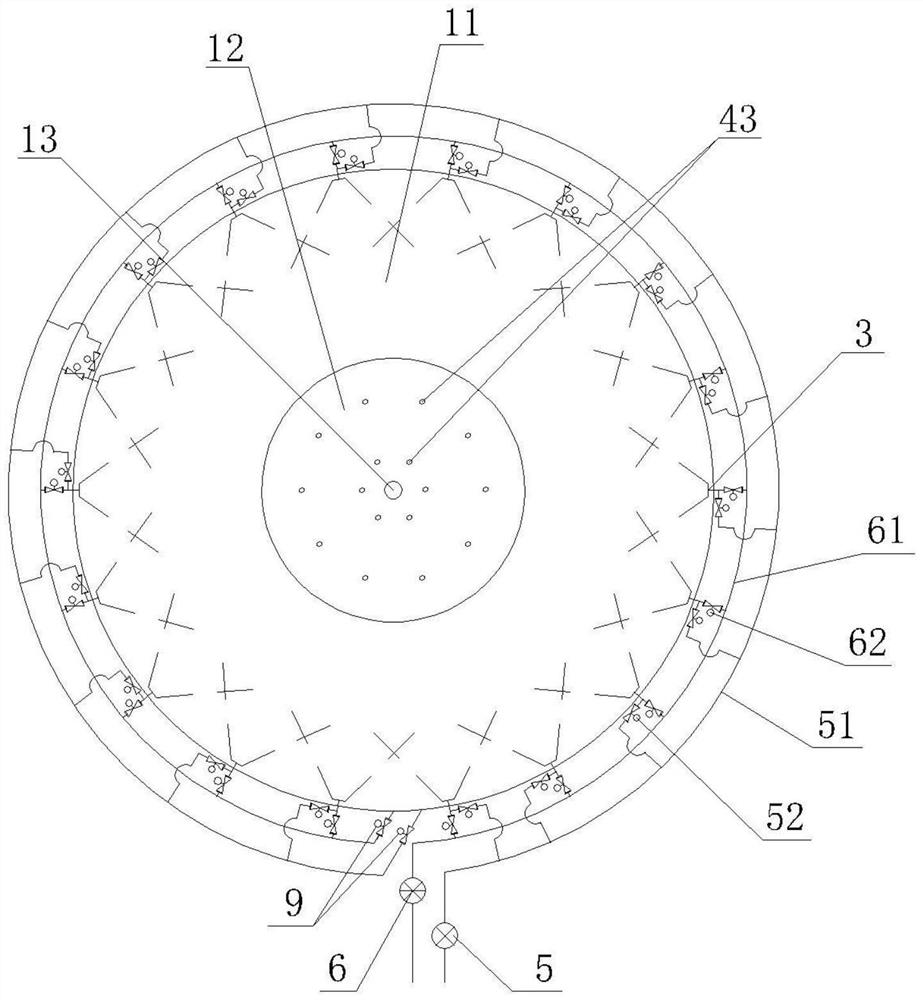

[0042] From figure 1 and figure 2 It can be seen that the rapid thickener in this embodiment includes a tank body 1, a feed box 2, a jet boost nozzle 3, a vibrating assembly 4, a pipeline pump 5 and a slurry pump 6,

[0043] The tank body 1 includes a separated transitional collection area 11, a compression vibration thickening area 12 and a sand discharge area 13 arranged coaxially and sequentially from top to bottom. The wall diameter is larger than the pool wall diameter of the compression vibration concentration zone 12, the pool wall diameter of the compression vibration concentration zone 12 is larger than the pool wall diameter of the sand release zone 13, and the separation transition collection zone 11 is divided into flocculation by the sand settling mud layer interface 14. Separation and clarification zone 111 and transition collection zone 112, a tank body overflow tank 15 is provided at the outer edge of the pool wall at the top of the flocculation separation an...

Embodiment 2

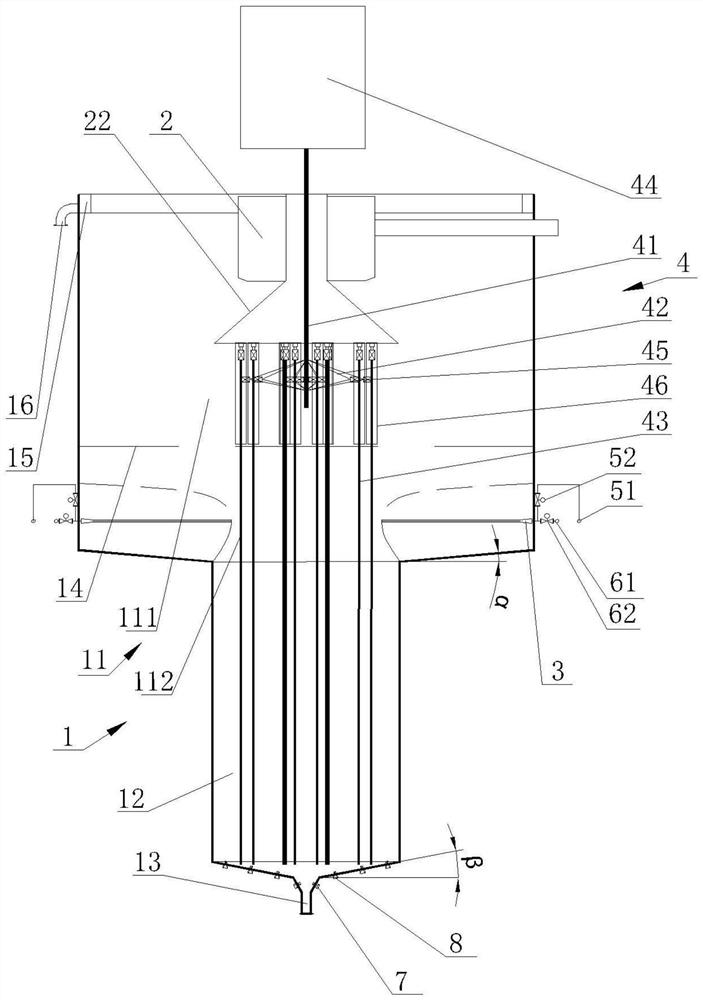

[0055] From image 3 It can be seen that compared with Embodiment 1, the difference of this embodiment is that a material distribution air guide hood 22 is provided at the center of the feed box, and the material distribution air guide 22 is connected to the bottom of the straight pipe section by a straight pipe section. Composed of round table sections, the top surface of the straight pipe section is arranged higher than the side wall of the feed box 2, the bottom surface of the round table section is arranged higher than the umbrella-shaped support 42, and the fixed shaft 41 is vertically arranged at the axis of the material distribution air guide cover 22; Several high-pressure air-driven and / or water-driven slurry-making activation nozzles 8 are arranged on the pool wall between the thickening zone 12 and the sand-discharging zone 13. On the wall of the pool, they are arranged staggered at intervals in a ring. When the slurry-making activation nozzle 8 adopts high-pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap