Label printing equipment

A label printing and labeling technology, which is applied in the direction of winding strips, sending objects, thin material processing, etc., can solve the problems of low efficiency of roll separation, long time spent on roll operation, and time spent by workers, so as to improve the efficiency of roll separation. Efficiency, efficiency improvement, and the effect of accelerating separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following is attached Figure 1-3 The application is described in further detail.

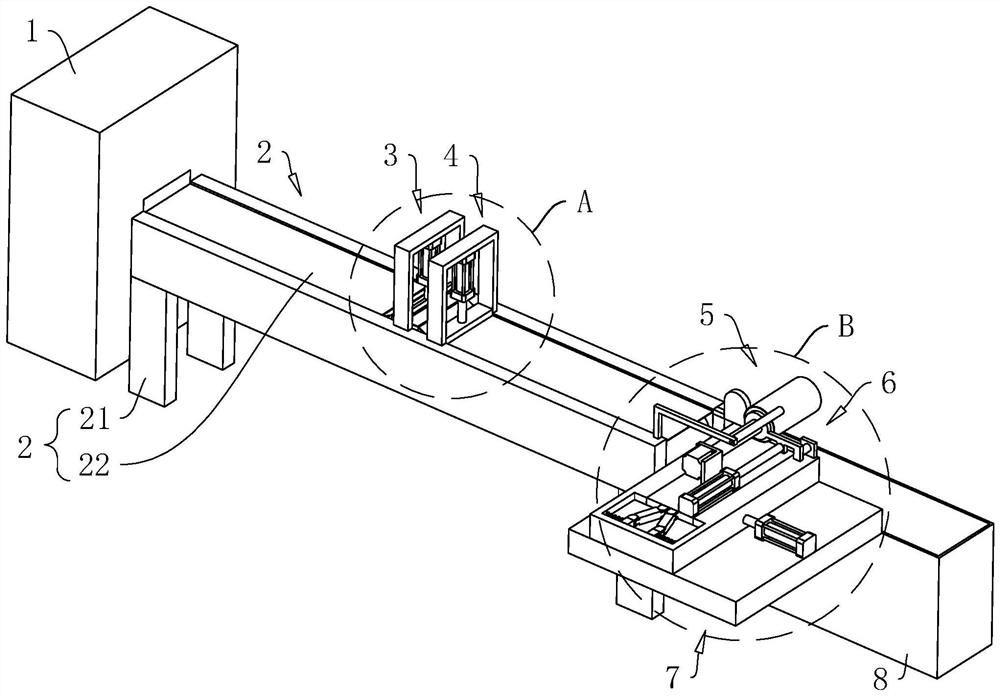

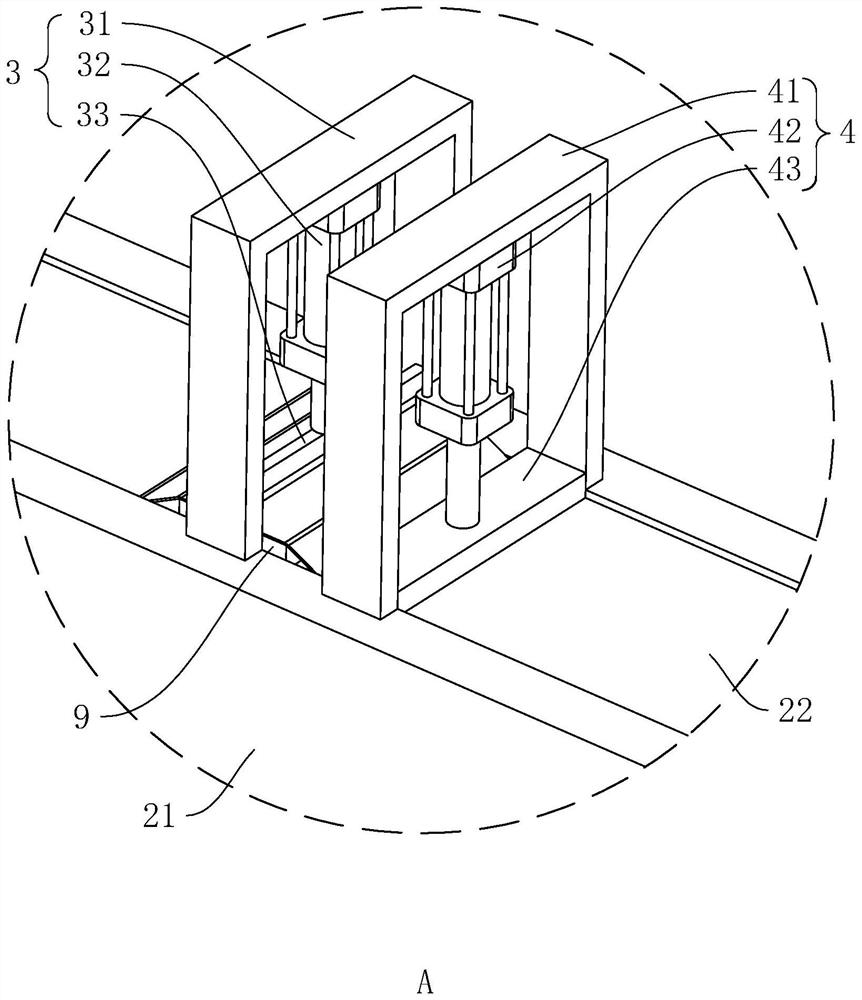

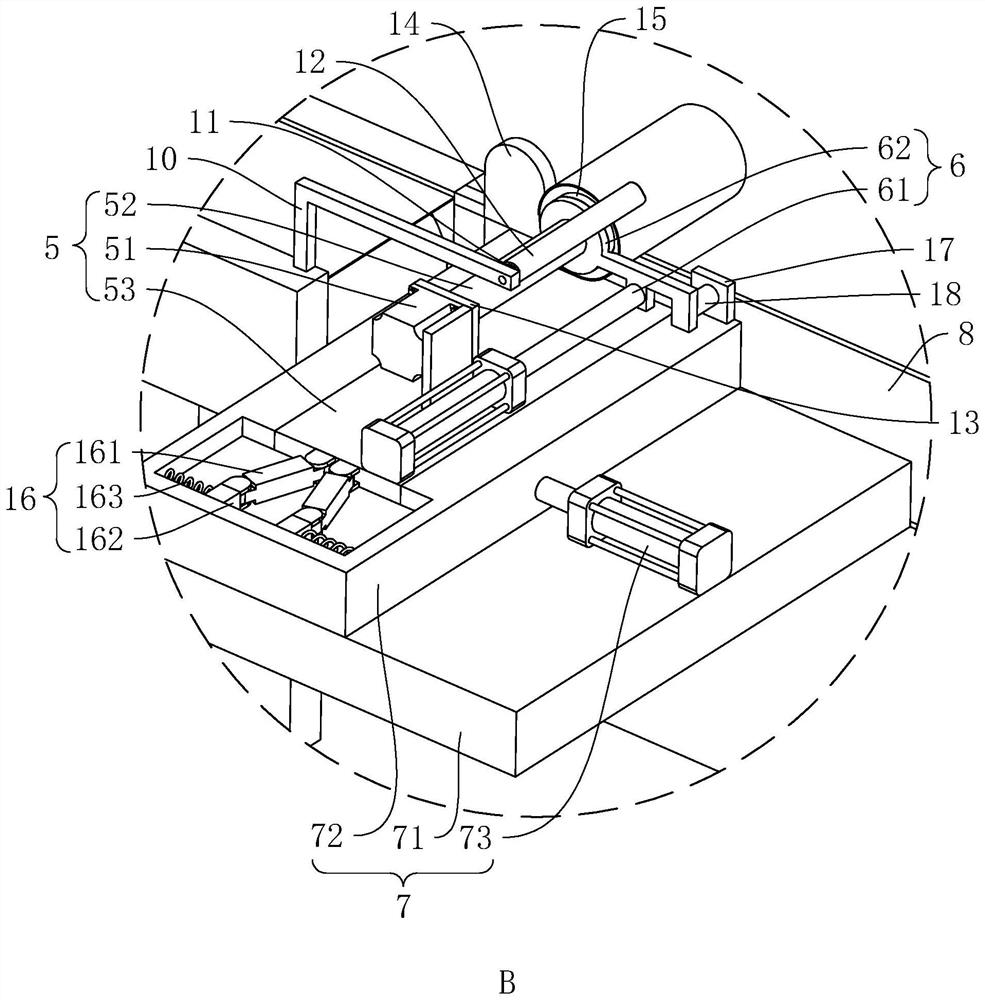

[0044] refer to figure 1 , the present application discloses a label printing device. A label printing device includes a label printing machine body 1 , a conveying component 2 , a cutting component 3 , a gluing component 4 , a winding component 5 and a discharging component 6 . The outlet of the label printer body 1 is connected to one end of the conveying assembly 2, the cutting assembly 3 and the gluing assembly 4 are sequentially connected to the middle of the conveying assembly 2, and the winding assembly 5 and the discharging assembly 6 are sequentially connected to the conveying assembly 2 away from the label One end of the printing machine body 1 and the end of the conveying assembly 2 away from the label printing machine body 1 are connected with a collection box 8 for collecting the labels that have been divided into rolls. The conveying component 2 transmits the one-pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com