Heat exchange piece for moisture exhaust device, moisture exhaust device and clothes dryer

A technology for heat exchange parts and moisture exhaust, which is applied in the field of clothes dryers and heat exchange parts, can solve the problems such as the environmental humidity and temperature of the clothes dryer are greatly affected, and achieve the effect of speeding up the drying process and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

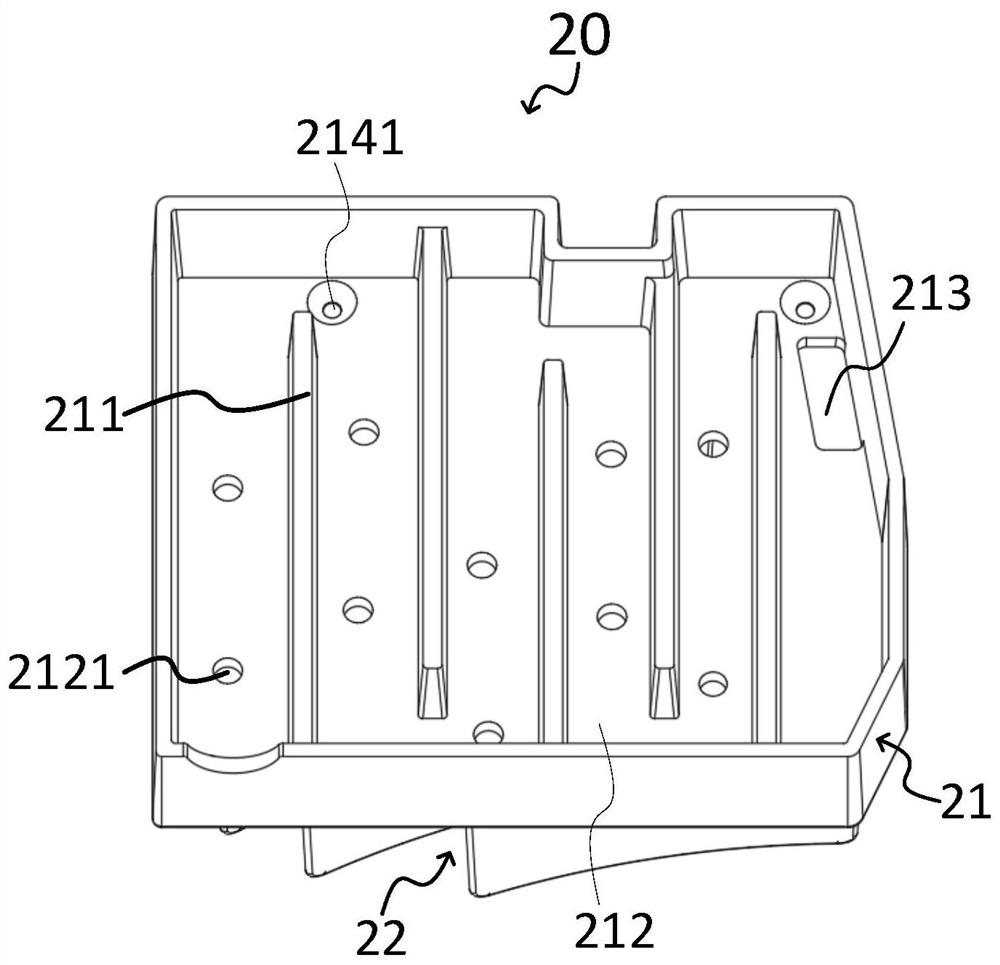

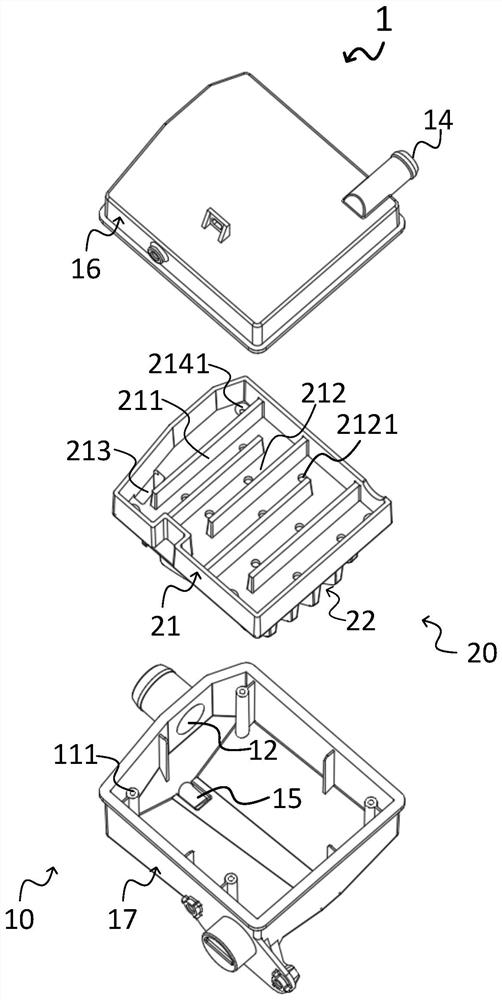

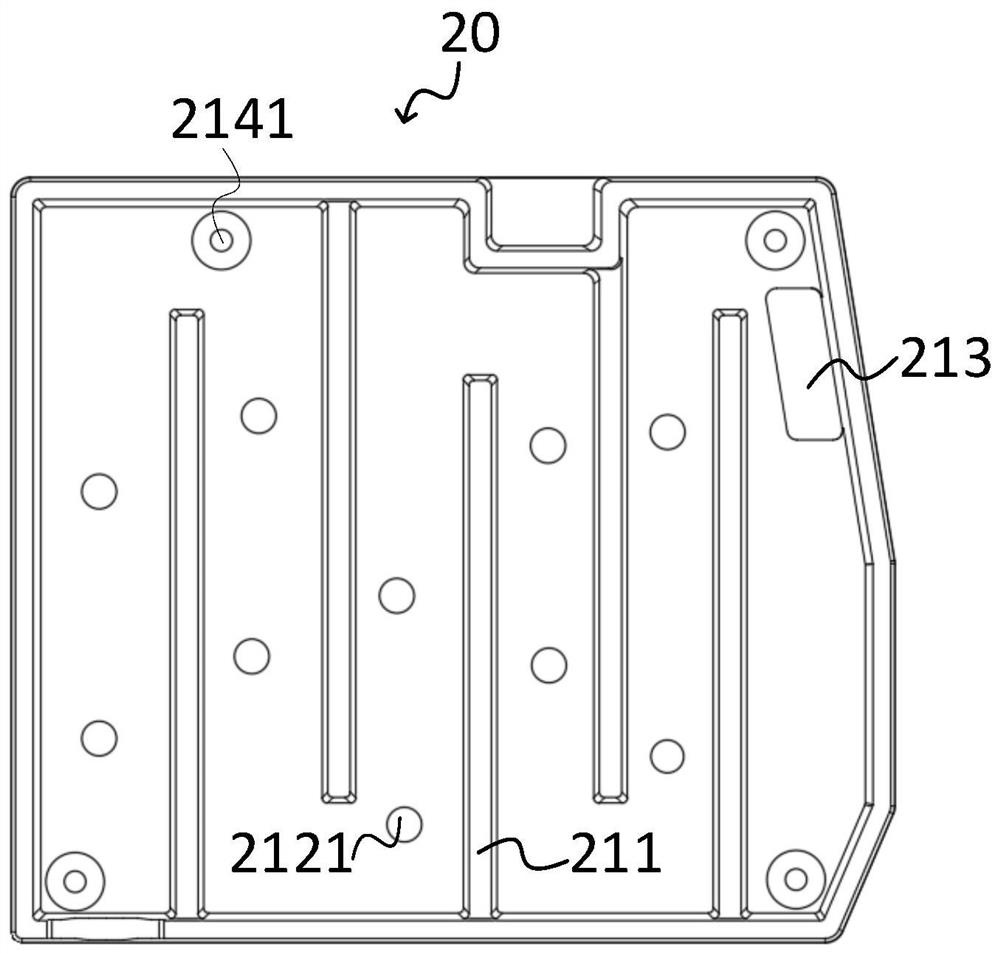

[0047] The invention provides a heat exchange element for a moisture exhaust device, such as Figure 1 to Figure 4 , Figure 6 , Figure 7 As shown, it includes a heat exchange element body 20 disposed in the device body 1 for dehumidification. The heat exchange element body 20 is provided with a cooling part 21; the cooling part 21 is provided with a cooling channel 212 for accommodating a cooling medium; wherein,

[0048] The cooling channel 212 is provided with a number of holes 2121, and the holes 2121 are connected with the cavity 11 of the device body 1; when the cooling medium flows in the cooling channel 212, part of the cooling medium flows from the several holes 2121 into the cavity 11; Specifically, in the process of flowing out from the plurality of holes 2121, part of the cooling medium contacts the hot and humid air in the cavity 11 during the flow, and can also contact the air when it flows to the inner wall of the cavity 11 and accumulates on the inner wall of...

Embodiment 2

[0077] The invention provides a heat exchange element for a moisture exhaust device, such as figure 2 , Figure 5 As shown, it includes a device body 1 arranged in the dryer body, and the device body 1 includes:

[0078] The casing 10 is provided with a cavity 11 for accommodating the heat exchange element body 20, for accommodating the heat exchange element body 20, and forming a temporary storage space for hot and humid air. After the hot and humid air enters the cavity 11, due to the contour of the cavity 11 The bondage of the hot and humid air reduces the flow velocity of the hot and humid air, so that the hot and humid air temporarily gathers in the cavity 11 to contact the heat exchange element body 20 in the cavity 11;

[0079] The heat exchange element body 20 of the heat exchange element used for the moisture exhaust device as described above is arranged in the cavity 11;

[0080] The hot and humid air generated by the drying drum of the clothes dryer body enters t...

Embodiment 3

[0091] The present invention provides a clothes dryer, which includes a clothes dryer body for performing drying. The clothes dryer body includes the device body 1 for a heat exchange element of a moisture exhaust device as described above. The main body of the clothes dryer includes a box body and a drying tube; the drying tube and the device body 1 are all arranged in the box body, and the air outlet 13 of the device body 1 is in one-way communication with the external environment of the box body to dissipate the damp heat in the cavity 11. The cooled and dehumidified air is discharged out of the box. When the dryer body executes the drying program, the hot and humid air in the drying cylinder is passed into the cavity 11 from the air inlet 12, and after being cooled by the cooling part 21, the moisture in the hot and humid air is condensed and removed, and then discharged from the air outlet 13 Outside the box. The cooling of the hot and humid air by the cooling unit 21 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com