Embedded steel bar clamping groove positioning device

A technology of positioning device and pre-embedded steel bars, applied in structural elements, building components, building reinforcements, etc., can solve problems such as component spacing adjustment, and achieve the effects of preventing safety accidents, improving stability, and quickly adjusting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

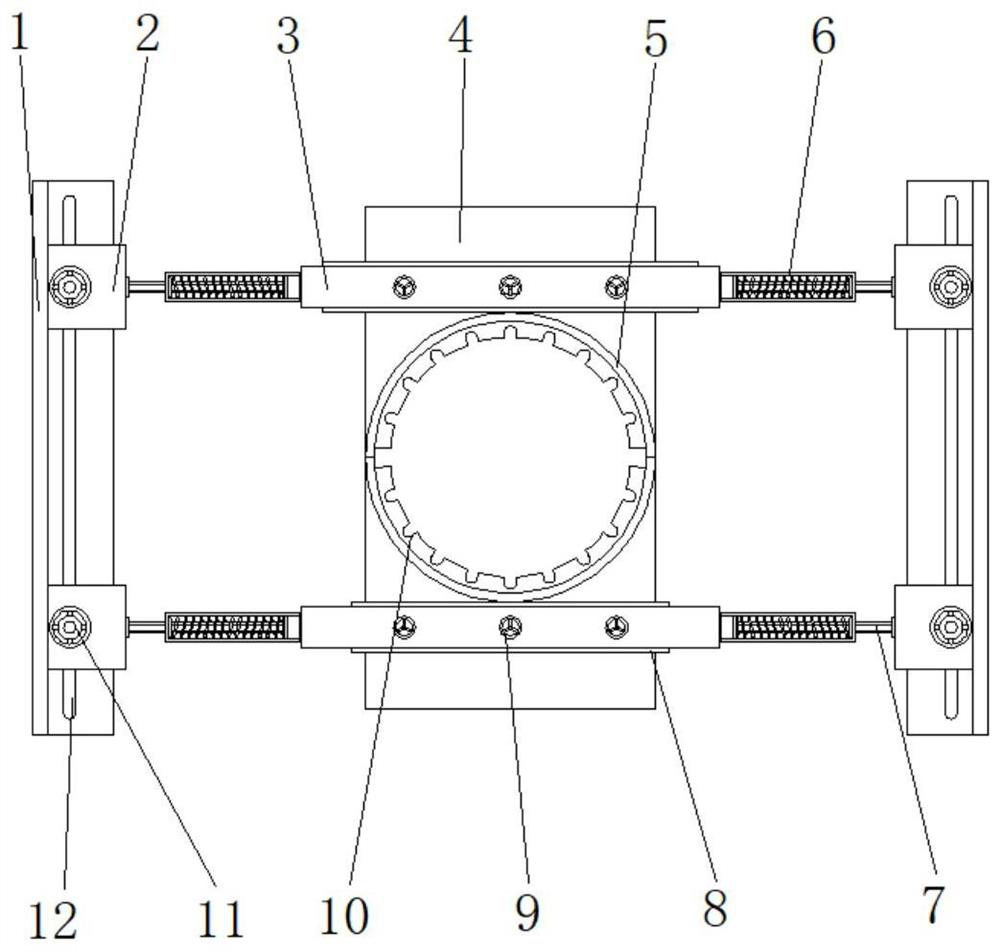

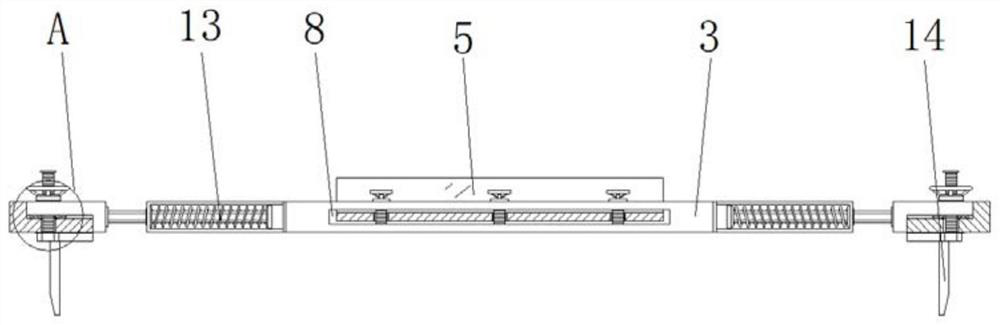

[0026] Example 1: See Figure 1-4 , a pre-embedded steel bar slot positioning device, including a positioning horizontal plate 3, two sets of positioning horizontal plates 3 are provided, and the two groups of positioning horizontal plates 3 are the same in size, and the two sides of the positioning horizontal plate 3 are respectively provided with adjustment grooves 1, The two sides of the positioning horizontal plate 3 are respectively provided with movable connecting plates 2, and the two sides of the positioning horizontal plate 3 are respectively fixedly connected with fixed cylinders 6, and the middle positions of the two ends of the positioning horizontal plate 3 are respectively provided with connecting sleeves 5, One end of the connecting sleeve 5 is fixedly connected with the installation board 4 respectively, and the connecting sleeve 5 is respectively semicircular, and one end of the inner side wall of the connecting sleeve 5 is evenly fixedly connected with a reinf...

Embodiment 2

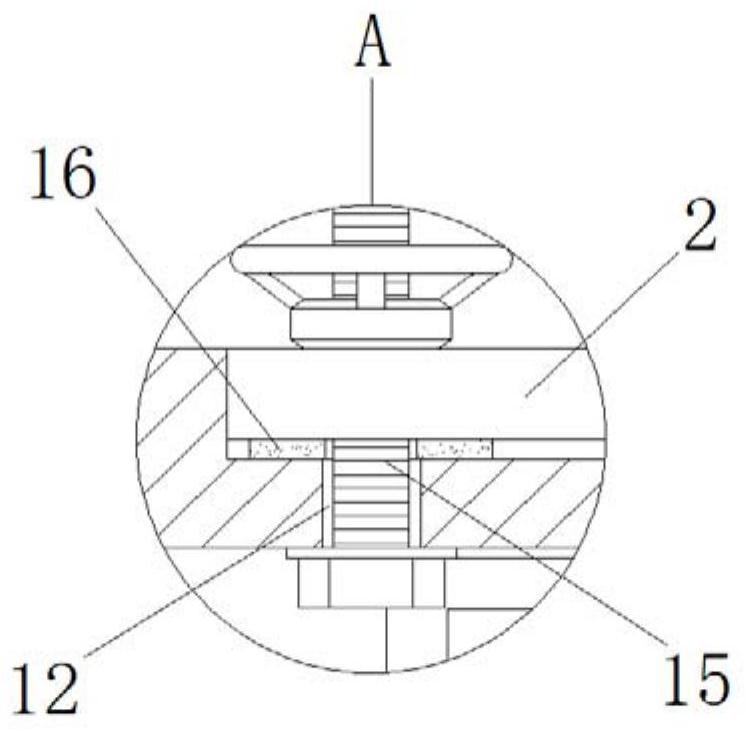

[0029] Embodiment 2: The interior of the adjustment groove 1 is respectively provided with an adjustment limit groove 12, and the two ends of the adjustment limit groove 12 are respectively penetrated with locking bolts 15, and the locking bolts 15 can slide inside the adjustment limit groove 12, The tops of the locking bolts 15 run through one side of the inside of the moving connecting plate 2 respectively, and the outer portions of the locking bolts 15 are respectively sleeved with locking turntables 11, and the insides of the locking turntables 11 are respectively provided with internal threads. Fastening gaskets 16 are respectively provided, and the fastening gaskets 16 are respectively arranged between the top end of the adjustment groove 1 and the bottom end of the moving connecting plate 2;

[0030] Specifically, such as figure 1 , figure 2 , image 3 with Figure 4As shown, and by sliding the locking bolt 15 inside the adjustment limit groove 12 provided inside th...

Embodiment 3

[0031] Embodiment 3: There are four sets of fixed cylinders 6, and the fixed cylinders 6 are respectively symmetrical about the vertical center line of the positioning horizontal plate 3, and one side of the fixed cylinder 6 is respectively inserted with a telescopic rod 7, and one of the telescopic rods 7 The sides are respectively fixedly connected with one side of the mobile connecting plate 2;

[0032] Specifically, such as figure 1 , figure 2 , Figure 4 with Figure 5 As shown, when in use, the purpose of connecting and fixing the moving connecting plate 2 and the positioning horizontal plate 3 is achieved by fixedly connecting the fixed cylinder 6 on both sides of the positioning horizontal plate 3 and the telescopic rods 7 inserted on one side respectively. The length between the positioning horizontal plate 3 and the moving connecting plate 2 can be adjusted by adjusting the length of the telescopic rod 7 plugged into the fixed cylinder 6, so that the width of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com