Anti-falling bearing device for structural column

A technology for structural columns and anti-dropping, which is applied in the direction of pillars, building structures, and on-site preparation of building components, and can solve problems such as inability to be placed in the center smoothly, structural columns toppled over, and difficult operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

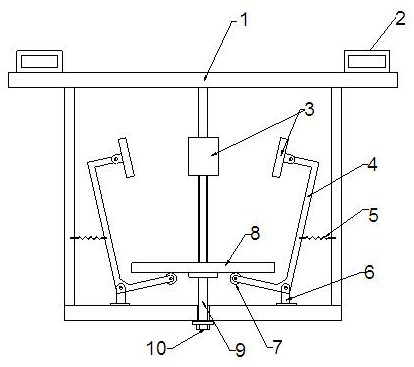

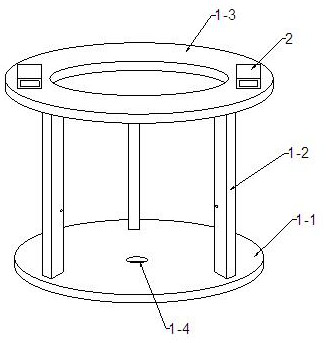

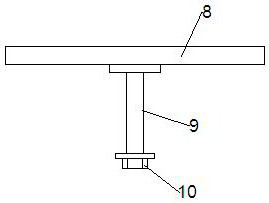

[0028] see Figure 1 to Figure 5 As shown, a structural column anti-drop receiving device provided by the present invention includes a frame 1 set on the bottom of the column, and the frame 1 is provided with a forklift fork groove 2. The frame 1 includes a cylinder and a bottom plate 1-1; the bottom plate 1- 1. There is a sliding hole 1-4 in the center; a pressing plate 8 is provided on the bottom plate 1-1, and a sliding bar 9 is provided on the lower side of the pressing plate 8, and the sliding bar 9 is movably installed in the sliding hole 1-4; a C-shaped lever is also provided The support arm 4, the outer end of the lower horizontal part 4-1 of the lever support arm 4 is arranged on the lower side of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com