Portable dust removal filter bag

A portable, filter bag technology, applied in the direction of dispersed particle filtration, separation method, dispersed particle separation, etc., to achieve the effect of improving practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

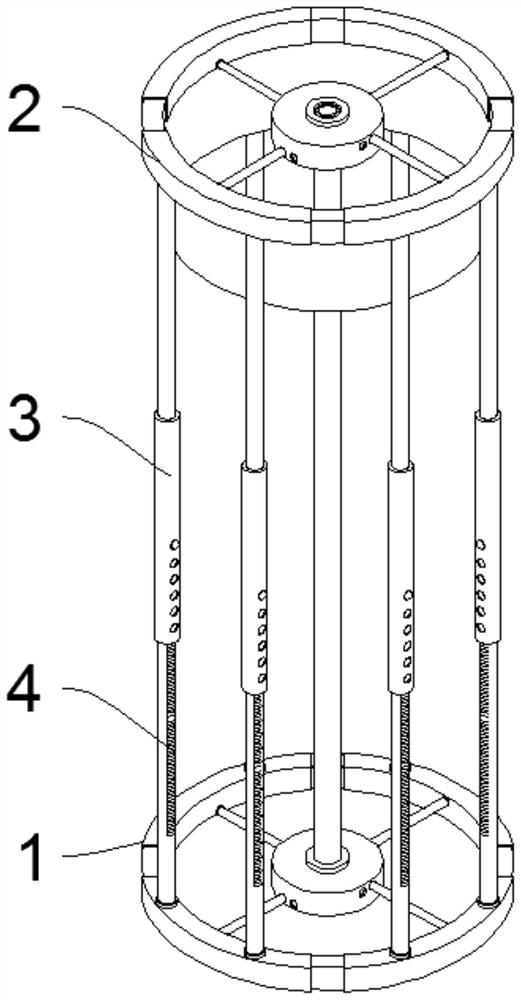

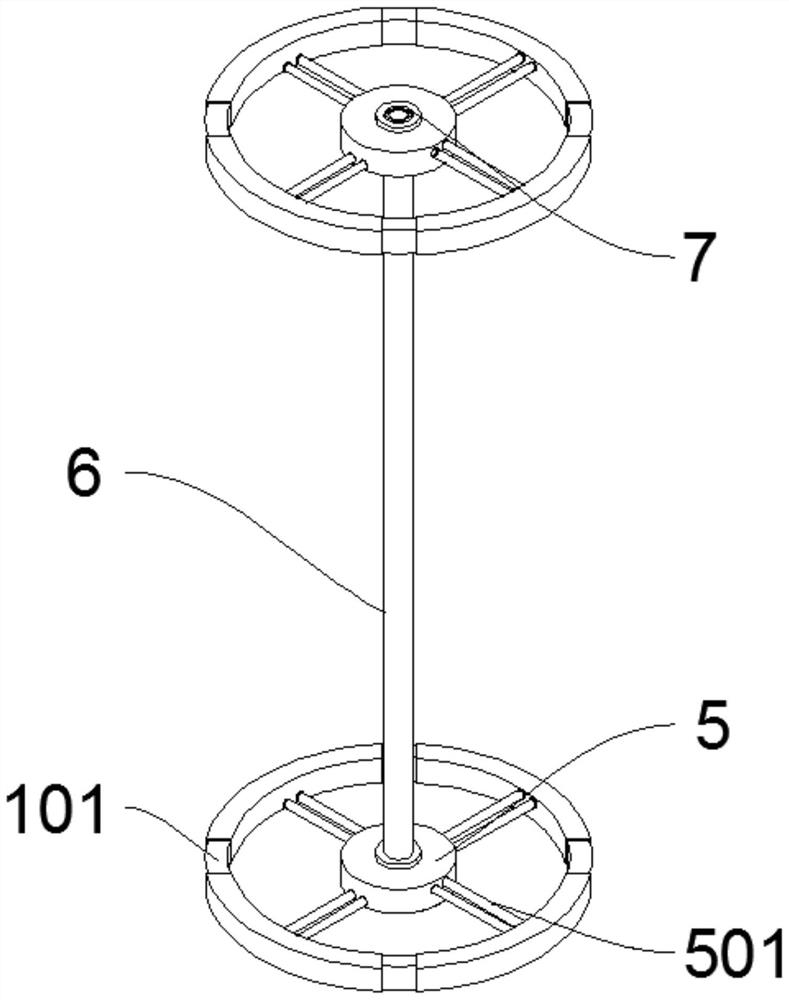

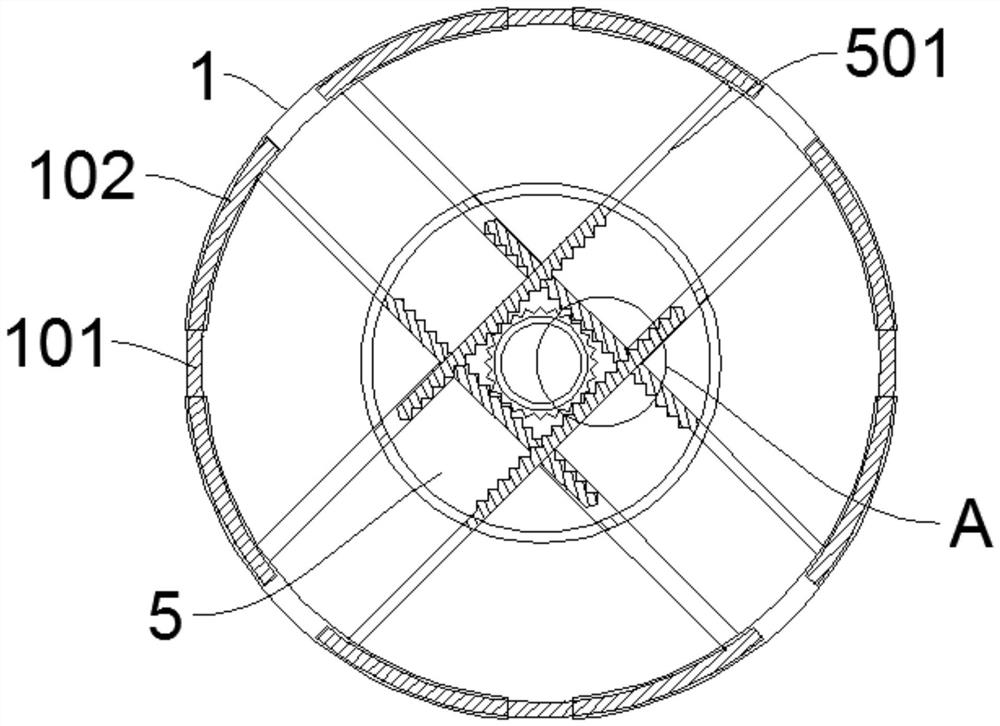

[0027] as attached figure 1 to attach Figure 5 Shown:

[0028] The present invention provides a portable dust removal filter bag, comprising an upper frame 2 and a lower frame 1, a telescopic mechanism 3 is installed equidistantly between the bottom end of the upper frame 2 and the upper end surface of the lower frame 1, the upper frame 2 and the lower frame 1 The frame 1 is composed of four sets of arc-shaped sleeves 102, and connecting arc-shaped tubes 101 are installed between the arc-shaped sleeves 102 through balls, and sleeve rods are installed equidistantly between the inner walls of the arc-shaped sleeves 102 501, and the other end of the sleeve rod 501 is jointly plugged with an adjusting disc mechanism 5, a connecting rod 6 is installed between the adjusting disc mechanisms 5, and one end of the connecting rod 6 runs through the adjusting disc mechanism 5 extends to the top, and is equipped with a regulating port 7 by a fixing piece.

[0029] Wherein, the adjusti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com