Heat conducting fiber, manufacture method thereof and illuminating device provided with same

A heat-conducting fiber and lighting device technology, which is applied in the direction of lighting devices, lighting device components, lighting device cooling/heating devices, etc., can solve the problems of heat dissipation system failure, affecting thermal conductivity, etc., and achieve good flexibility and high Reliability, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

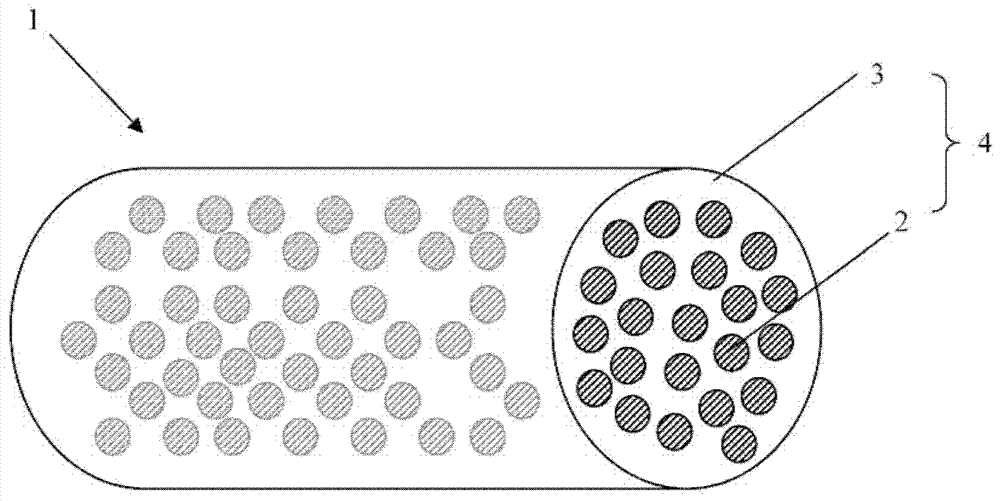

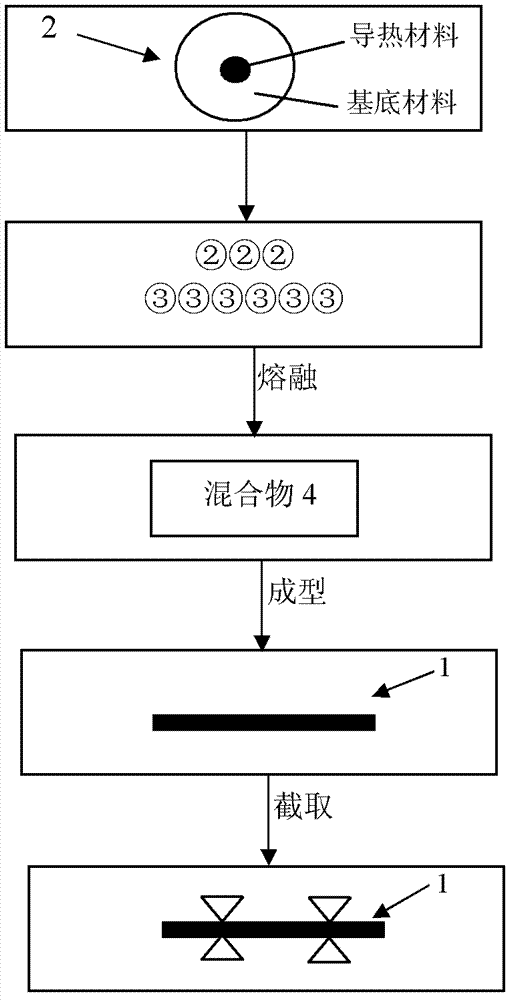

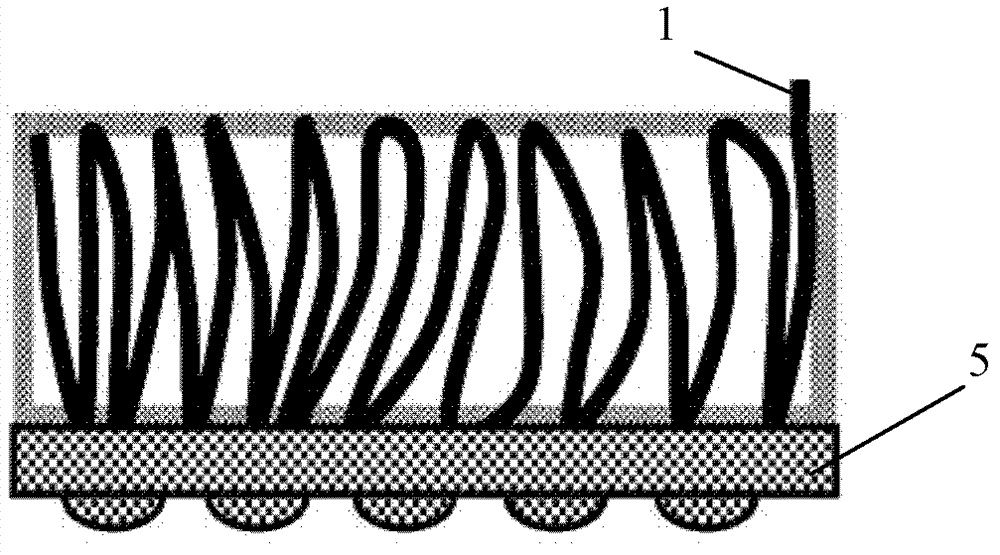

[0031] figure 1 A perspective view of a thermally conductive fiber according to a first embodiment of the present invention is shown. Elongated heat-conducting fibers 1 are schematically shown in the figure. In practice, the diameter of the thermally conductive fibers 1 may be less than 1 mm. After a large number of heat-conducting particles 2 and plastic particles 3 (shown directly as the matrix of the heat-conducting fiber 1 in the figure), for example, after melting, the mixture 4 of the heat-conducting particles 2 and the plastic particles 3 can be processed into a fibrous product through a molding process, The thermally conductive fibers 1 are formed after the cooling treatment. In order to achieve good heat conduction properties, the hard or flexible base material is especially doped with micron or nanoscale heat conduction materials, thereby forming heat conduction particles 2 . The thermally conductive material may account for 20%-50% of the thermally conductive par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com