Environment-friendly and efficient sand making system for mine

An environmentally friendly and efficient technology, applied in grain processing and other directions, can solve problems such as stone scattering, and achieve the effect of preventing scattering and good synchronization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

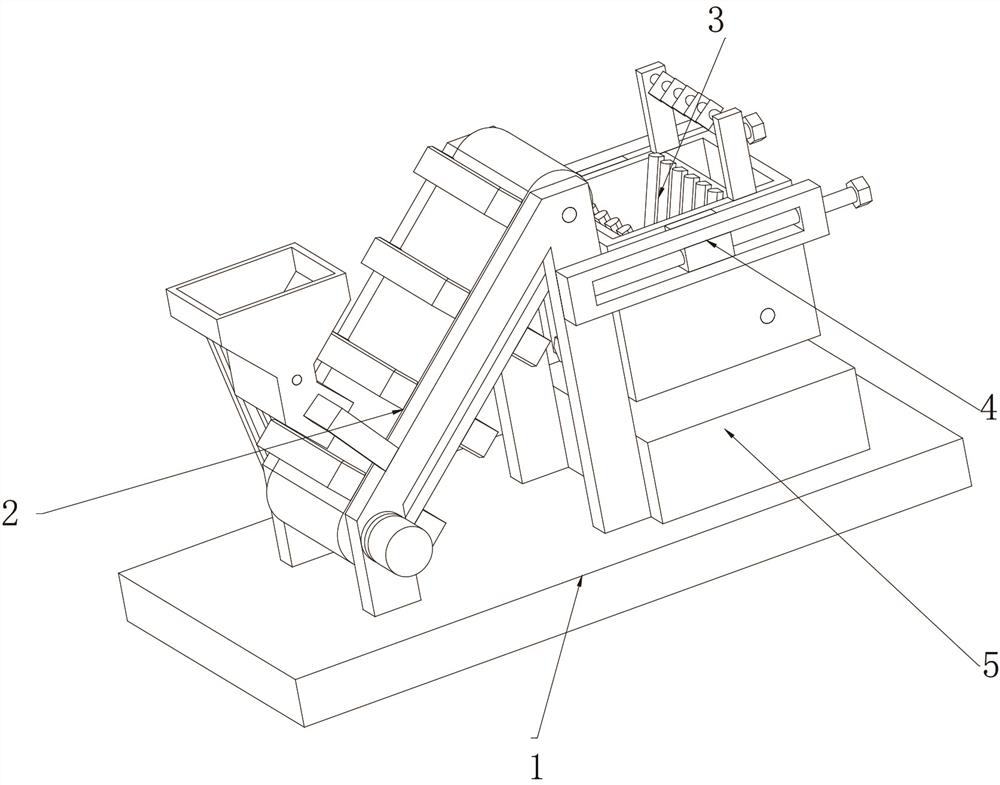

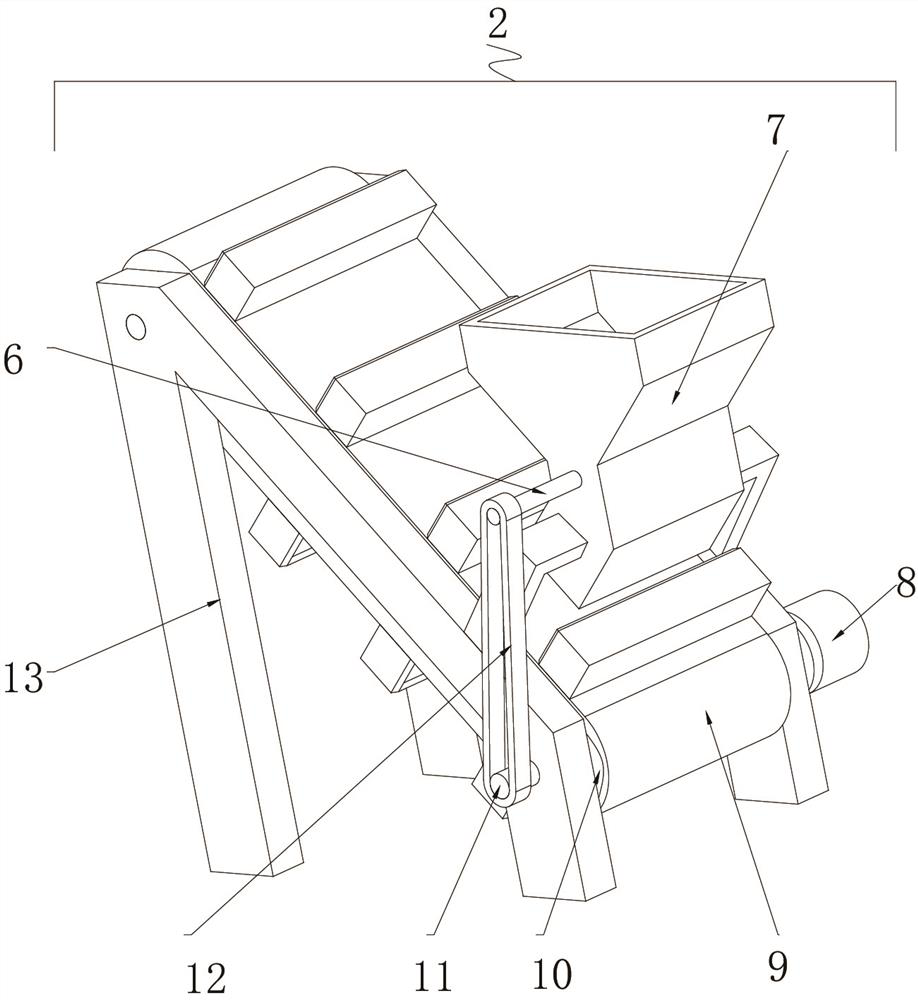

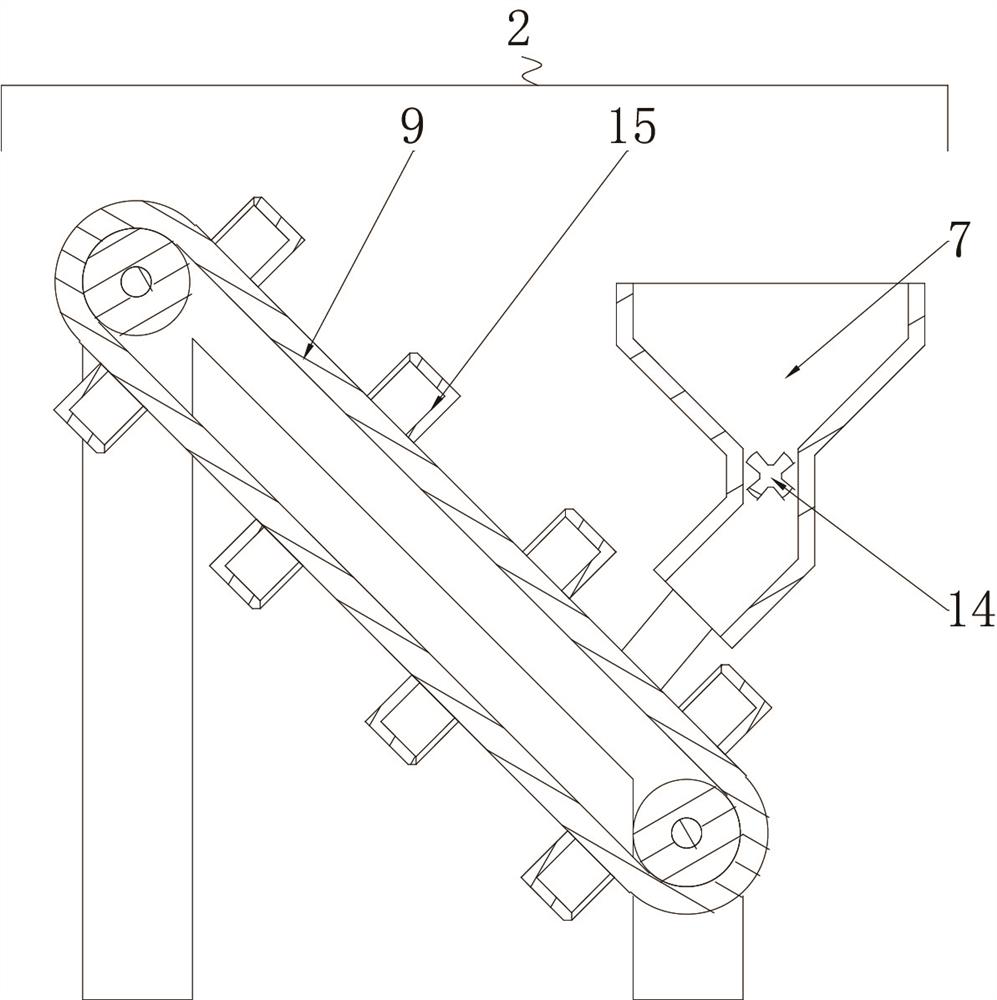

[0041] An environmentally friendly and efficient sand making system for mines, such as Figure 1-3 As shown, it includes a base 1, the top outer wall of the base 1 is provided with a conveying mechanism 2, one side of the conveying mechanism 2 is connected with a crushing mechanism 3 through an adjusting mechanism 4, and the conveying mechanism 2 includes a funnel 7 and a conveying bracket 13 , the inner walls on both sides of the conveying bracket 13 are connected with conveying rollers 10 through the conveying shaft 11, and the outer walls of the two conveying rollers 10 are matched with conveying belts 9, and the outer walls of the conveying belts 9 are fixedly installed with uniform Material bowl 15, the section of described material bowl 15 is " L " type, and buckle is installed on the outer wall of conveyer belt 9 , described funnel 7 is fixedly installed on the top outer wall of conveying bracket 13, and the inner wall of described funnel 7 passes drop The material shaf...

Embodiment 2

[0046] An environmentally friendly and efficient sand making system for mines, such as Figure 4 As shown, in order to solve the adjustment problem; the present embodiment makes the following improvements on the basis of Embodiment 1: the adjustment mechanism 4 includes two adjustment frames 27, and the inner walls of the two adjustment frames 27 pass through the slides provided therein. The groove 17 is slidably connected with a slide block 18, the slide block 18 and the crushing box 20 are fixed by bolts, the inner wall of the adjusting frame 27 is rotatably connected with a lead screw 16, the lead screw 16 is threadedly connected with the slide block 18, and the lead screw 16 is connected with the slide block 18 by threads. One side outer wall of the bar 16 is welded with a screw head 19; because the stone material falls into the crushing box 20 in a parabola, in fact, the size of the stone material and the speed of conveying all have an impact on the falling point of the st...

Embodiment 3

[0049] In order to realize that the work of the second motor 21 can be started automatically when stone material falls on the conveyor belt 9 without manual operation.

[0050] Such as Figure 7 and Figure 9 As shown, in this embodiment, one of the bowls in every two spaced bowls 15 includes a movable plate 151 and a base 152, and the movable plate 151 can move towards the motor one 8 on the base 152. Side sliding, the inside of the material bowl 15 is provided with a first spring 153 that resists and supports the movable plate 151, the inner side of the movable plate 151 is provided with a contact point 154, and a contact column is also provided inside the material bowl 15 155, the contact 154 and the contact post 155 are used to communicate with the circuit of the second motor 21. It should be noted that the contacts 154 and contact columns 155 of different groups are connected in parallel with circuits of other groups, that is, when only one group of contacts 154 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com