Workpiece fixing device for mechanical welding

A technology for mechanical welding and fixing devices, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of danger to operators, increase of welding time, and decrease of welding efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

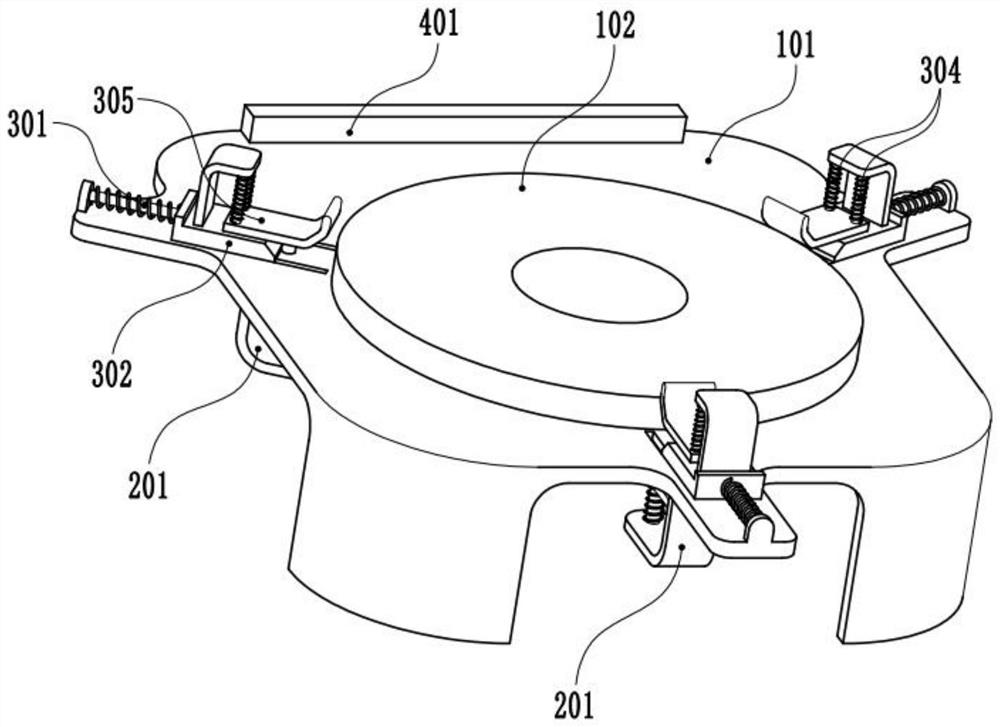

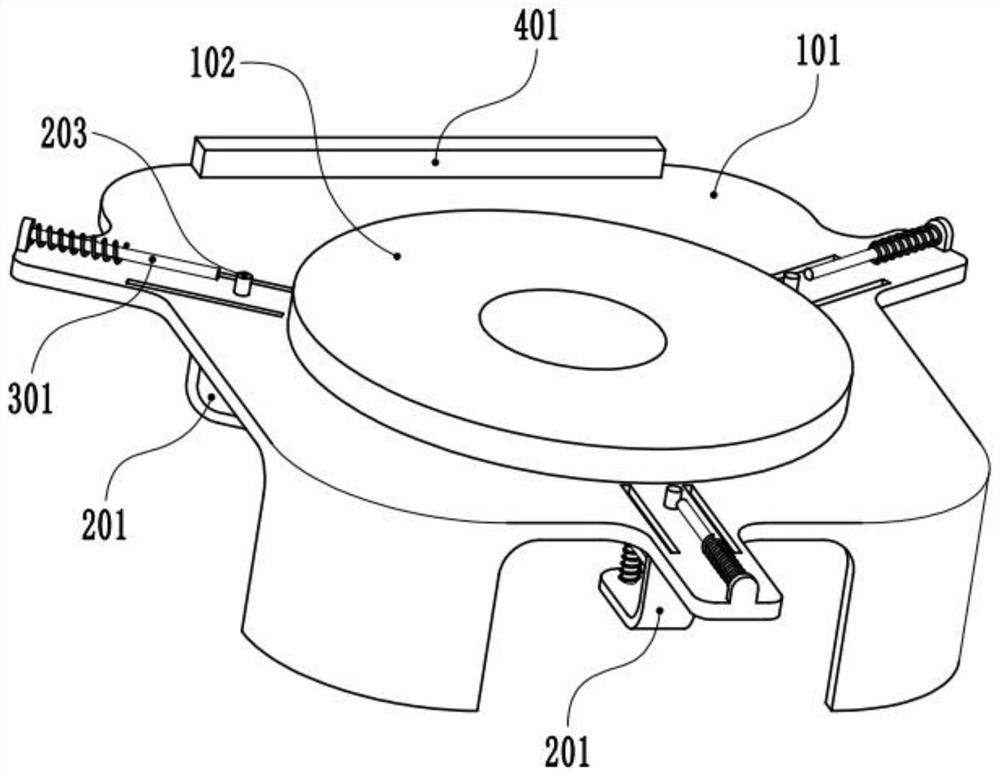

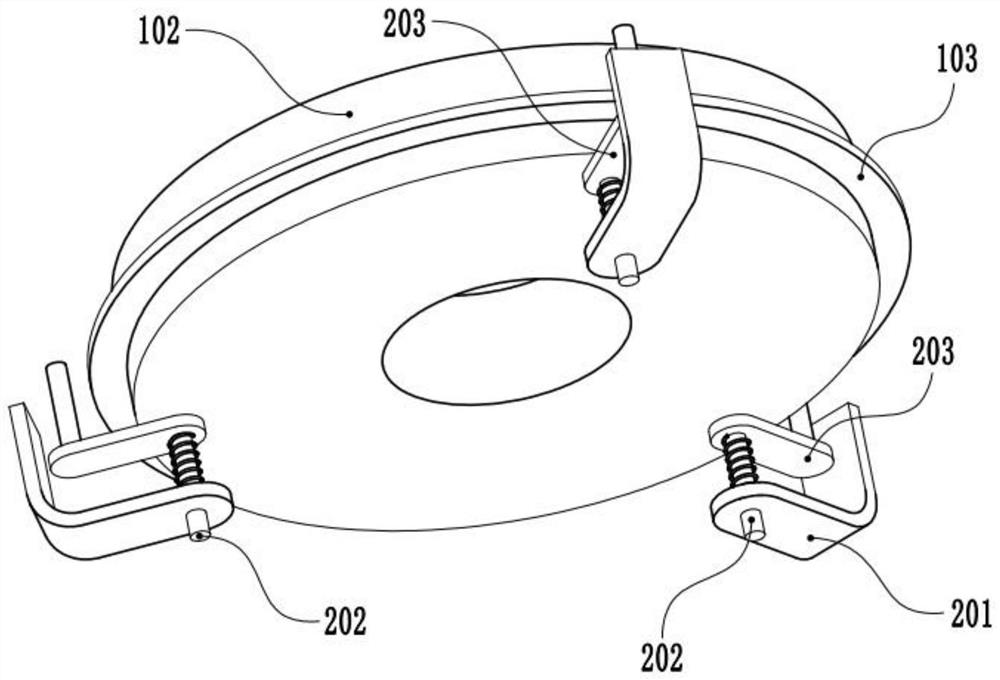

[0028] Attached below Figure 1-5 In detail, the workpiece fixing device for mechanical welding includes a support table 101, a lifting pallet 102, a squeezing member and a linkage member. The lifting pallet 102 is slidably connected to the support table 101. The squeezing member and the linkage member are all provided with three The three linkage components are fixedly connected to the support table 101 by welding, the three squeeze components are slidingly connected with the support table 101 through round holes, and the three squeeze components are in contact with the three linkage components respectively.

[0029] Further, the support table 101 plays the role of load-bearing connection. The support table 101 is provided with three support legs to realize the support and fixation of the support table 101. When there is no welding on the lifting pallet 102,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com