Multi-workstation stretching measuring and welding device

A welding device and multi-station technology, applied in the direction of measuring devices, welding equipment, laser welding equipment, etc., can solve the problems of unfavorable large-scale production, prolonging the production cycle of mask plates, etc., and achieve the reduction of later detection and fixed time and space Occupies the effect of small volume and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

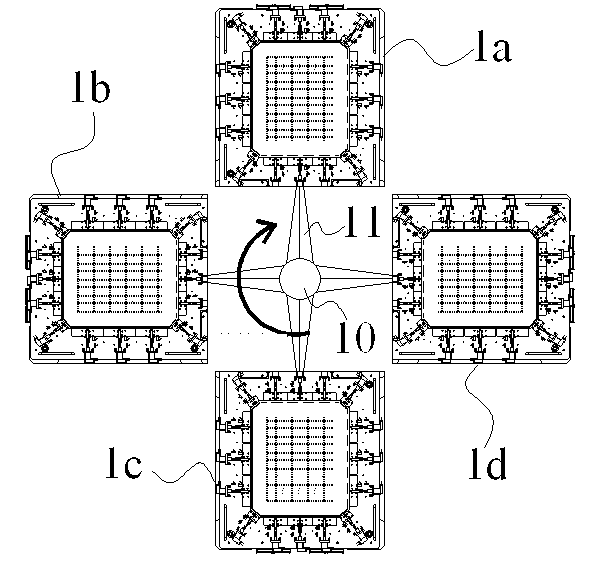

[0017] figure 1 Shown is a schematic diagram of the base distribution plan of the embodiment of the present invention, which is the main part of a multi-station stretching net measuring welding device, including four operating bases 1a, 1b, 1c, 1d, a rotating shaft 10 and a control base The platform rotation mechanism 11, the base platforms 1a, 1b, 1c, 1d can rotate around the rotating shaft 10 under the action of the rotation mechanism 11, and the rotation mechanism 11 in this embodiment is a link mechanism.

[0018] The number of base stations described in the embodiment is 4, and the relationship between them is as follows figure 1 As shown, further, the angle at which the base of the device rotates each time is related to the number of bases. In this embodiment, bases 1a-d can be moved along each time figure 1 The rotation angle shown in the rotation axis 10 is 90°.

[0019]

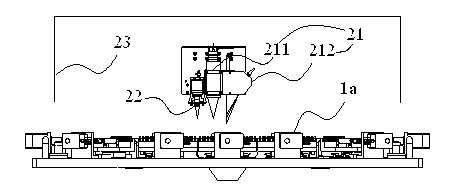

[0020] figure 2 Shown is the schematic diagram of the position of the measurement welding un...

Embodiment 2

[0023] A multi-station stretching net measuring and welding device, including a plurality of operating bases, a rotating shaft, a measuring unit, a welding unit, and a mechanism for controlling the rotation of the base, is characterized in that the base can be rotated around the rotating shaft under the action of the rotating mechanism. turn.

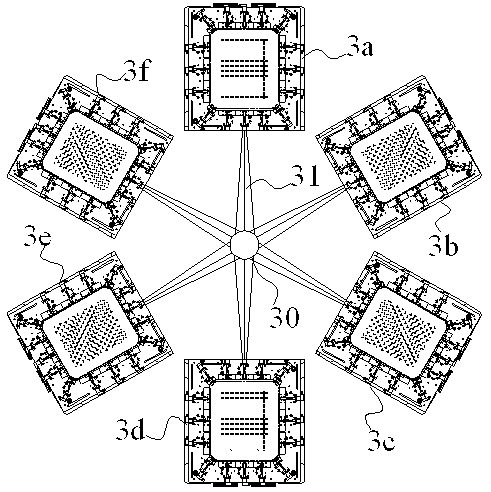

[0024] image 3 Shown is a schematic diagram of the planar arrangement of bases in another embodiment of the present invention, 3a, 3b, 3c, 3d, 3e, 3f are operating bases; 30 is a rotating shaft, and 31 is a rotating mechanism.

[0025] The number of operating bases shown is 6, which is the same as the basic operation method of the foregoing embodiment, the difference is that two sets of the measurement welding units are provided in this embodiment, and as the best choice, the measurement welding units are respectively arranged on Above the two diagonal abutments, such as image 3 As shown, the measurement welding unit can be arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com