Rapid decarburization method for RH refined ultra-low carbon steel

An ultra-low carbon steel, fast technology, applied in the field of steelmaking, can solve the problems of long refining time, slow vacuum decarburization speed, and large process temperature drop, and achieve short refining time, fast vacuum decarburization speed, and process temperature drop small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: The method for rapid decarburization of ultra-low carbon steel refined by RH adopts the following specific processes.

[0040] The tapping capacity of the converter is 275 tons, the carbon content of the molten steel is 0.052wt%, the P content is 0.011wt%, the S content is 0.0085wt%, the tapping temperature is 1660°C, and the end point oxygen is 485ppm; the tapping temperature is 1 / 3 Add lime particles to the ladle according to the addition of 550kg; the particle size of the lime particles is 3-5mm, the content of calcium oxide is 92%, and the activity is 380ml; after the steel is tapped, the slag layer is in a molten state, so add 550kg aluminum slag, the metal aluminum content is 40% in the described aluminum slag.

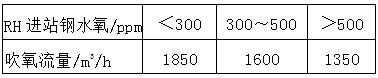

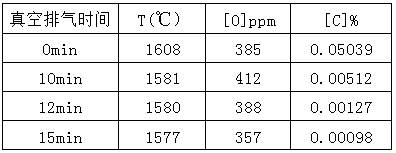

[0041] After the molten steel reaches RH, measure the temperature to determine the oxygen and carbon content: the oxygen content is 285ppm, the carbon content is 0.042w%, and the temperature is 1608°C; select the RH pre-vacuum mode, and pump...

Embodiment 2

[0045] Embodiment 2: The method for rapid decarburization of ultra-low carbon steel refined by RH adopts the following specific process.

[0046] The steel output of the converter is 274 tons, the carbon content of the molten steel is 0.045wt%, the P content is 0.013wt%, and the S content is 0.0072wt%. Add lime particles to the ladle according to the addition of 685kg; the particle size of the lime particles is 3-5mm, the content of calcium oxide is 90.2%, and the activity is 330ml; 680kg aluminum slag, the metal aluminum content is 42% in the described aluminum slag.

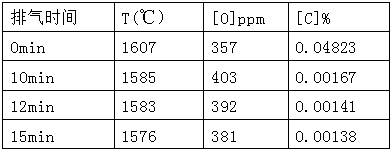

[0047] After the molten steel reaches RH, measure the temperature and determine the oxygen and carbon content: the oxygen content is 357ppm, the carbon content is 0.04w%, and the temperature is 1607°C; select the RH pre-vacuum mode, and pump the vacuum to 120mbar; lift the ladle, dip the tube Insert it 400mm below the liquid steel surface, start the vacuum pump, start the exhaust, and the vacuum degree is 150m...

Embodiment 3

[0051] Embodiment 3: The method for rapid decarburization of ultra-low carbon steel refined by RH adopts the following specific process.

[0052] The steel output of the converter is 275 tons, the carbon content of the molten steel is 0.045wt%, the P content is 0.012wt%, and the S content is 0.0079wt%. Add lime particles to the ladle according to the addition of 960kg; the particle size of the lime particles is 3-4mm, the content of calcium oxide is 94%, and the activity is 372ml; Carry out strong stirring to ensure that the slag layer is completely melted and then close the bottom blowing of the ladle, and add 825kg of aluminum slag in the ladle, the metal aluminum content in the aluminum slag is 41%.

[0053] After the molten steel reaches RH, measure the temperature to determine the oxygen and carbon content: the oxygen content is 504ppm, the C content is 0.040%, and the temperature is 1605°C; select the RH pre-vacuum mode, and pump the vacuum to 125mbar; jack up the ladle,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com