Peristaltic pump

A peristaltic pump and pump tube technology, applied in the field of peristaltic pumps, can solve the problems of easy falling off, complex structure, low control precision, etc., and achieve the effect of good compression effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

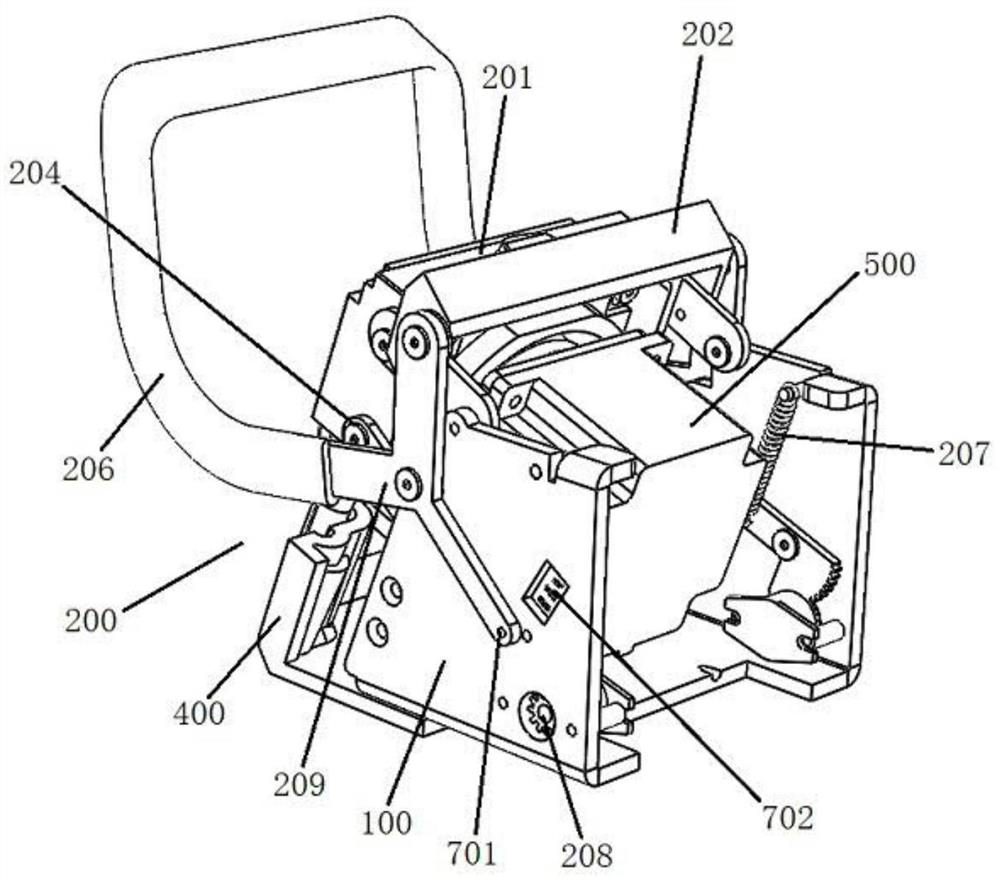

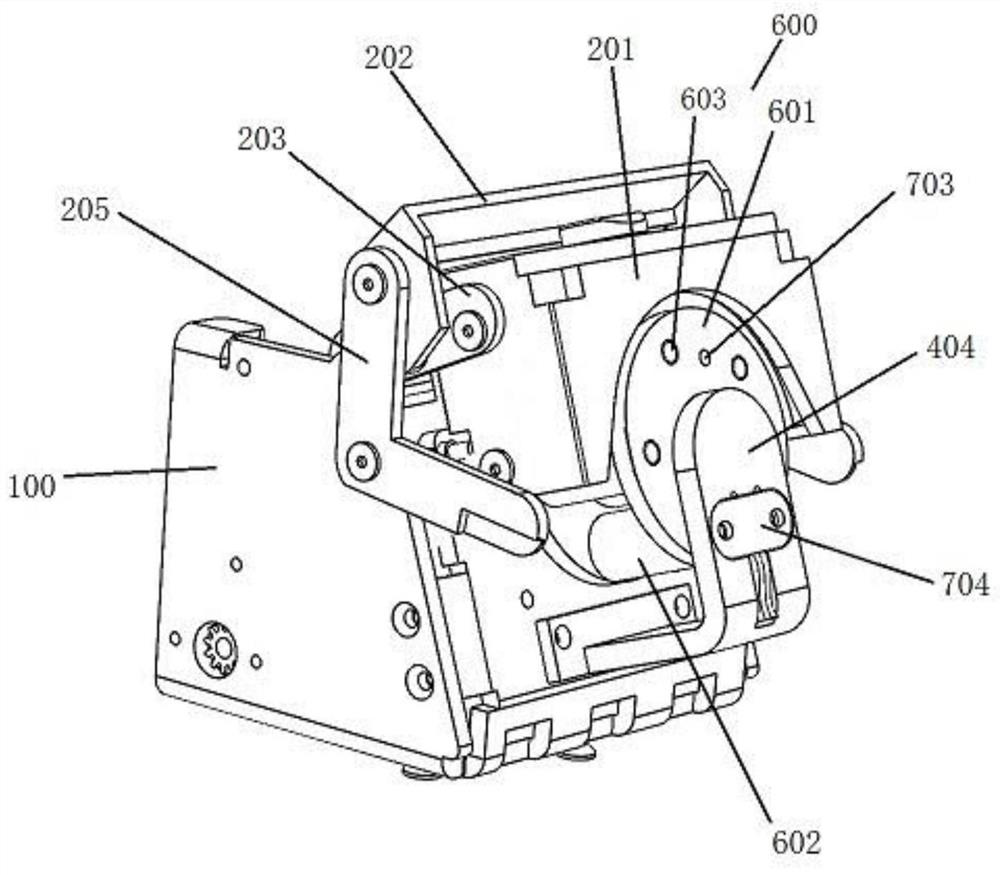

[0030] see Figure 1 to Figure 4 , the present invention provides a peristaltic pump, including a frame 100 , a rocker assembly 200 , a pressing block 300 , a pump tube fixing assembly 400 , a driving motor 500 and a roller assembly 600 . The drive motor 500 is installed in the frame 100, the output shaft of the drive motor 500 is fitted with a roller assembly 600, and the pump tube 101 is placed on the roller assembly 600, and the roller assembly 600 is used to drive the pump tube 101 to peristalticly supply liquid under the drive of the drive motor 500. The pump tube fixing assembly 400 is fixedly connected to the frame 100, the rocker assembly 200 is rotatably arranged on the frame 100, the pressing block 300 is arranged on the rocker assembly 200, the pressing block 300 is located above the roller assembly 600, and the rocker assembly 200 can drive the pressing block 300 close to the roller assembly 600 to cooperate with the roller assembly 600 to press the pump tube 101 o...

Embodiment 2

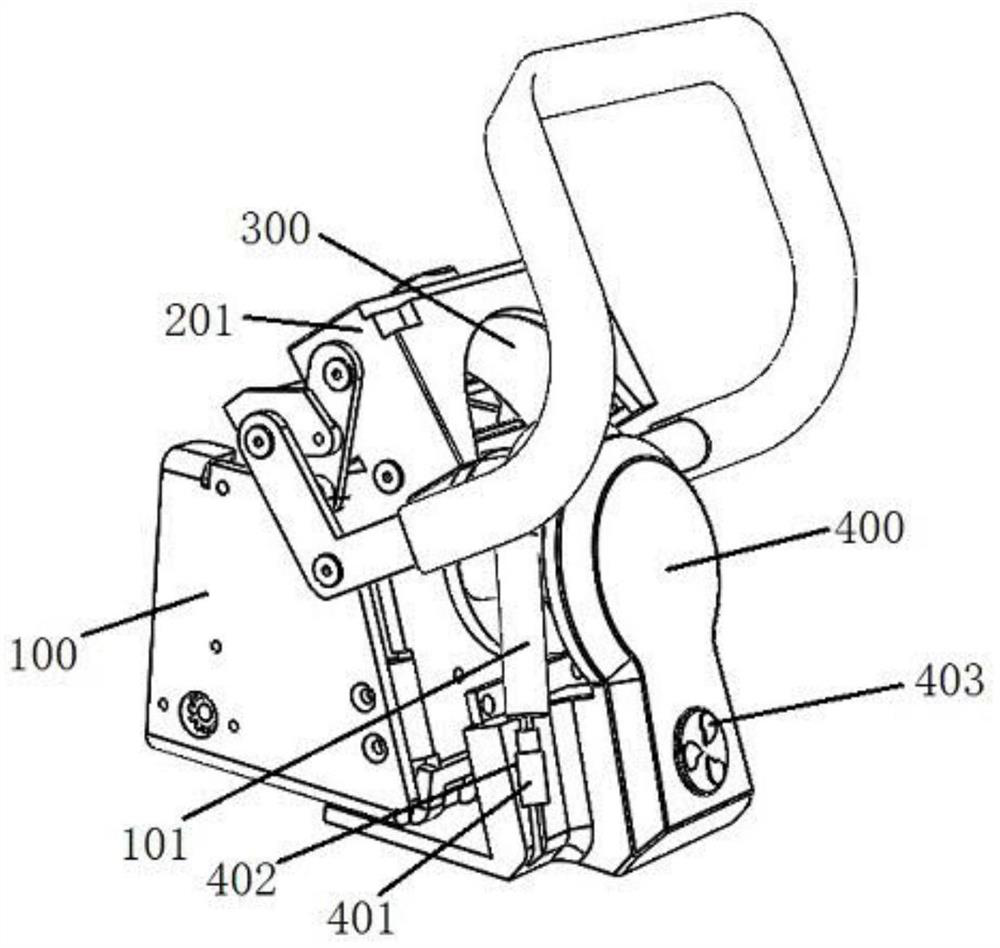

[0047] see image 3 , this embodiment provides a peristaltic pump. This embodiment is an improvement made on the technical basis of the first embodiment above. The difference between this embodiment and the first embodiment is that an indicator light 403 is installed on the lower part of the pump tube fixing assembly 400, and the flashing frequency of the indicator light 403 is controlled by the microcontroller. control, the flickering frequency of the indicator light 403 is related to the liquid supply rate of the pump tube 101 .

[0048] In this embodiment, three indicator lights 403 are evenly embedded in the outer surface of the lower part of the pump tube fixing assembly 400 along the ring, and the indicator lights 403 are electrically connected to the microcontroller. Adjust the flashing frequency of the indicator light 403 to be consistent or proportional to the liquid supply rate of the pump tube 101 through the rotation of the roller assembly 600, that is, the faster...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com