Integrated waste incineration and transportation device

A transportation device and waste incineration technology, which are applied in incinerators, combustion methods, solid separation, etc., can solve the problems that the treatment effect cannot meet the process requirements and the combustion is incomplete, and achieve the efficiency of waste incineration and ash transportation and treatment. The effect of improving, sufficient combustion, and large-capacity processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

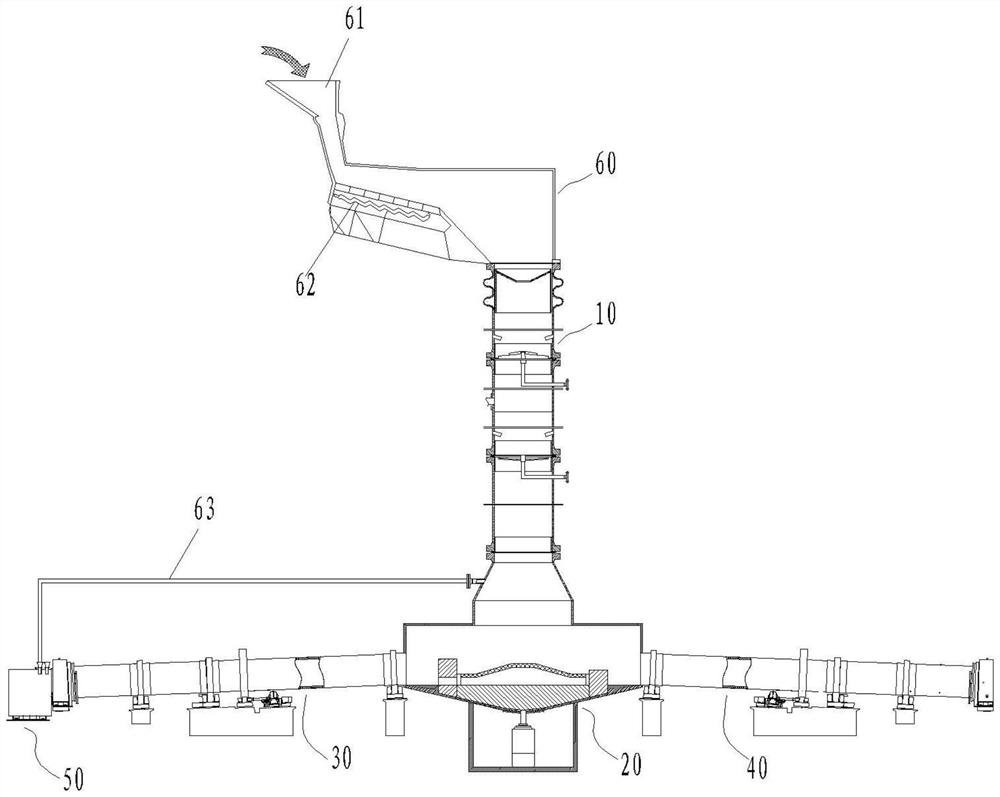

[0033] As shown in the figure, this embodiment provides an integrated waste incineration transportation device, which includes a vertical incineration tower and an ash transfer treatment device connected to the bottom of the vertical incineration tower. In this embodiment, the vertical incineration tower And the two large sections of the ash transfer treatment device explain the entire incineration and transportation integrated machine;

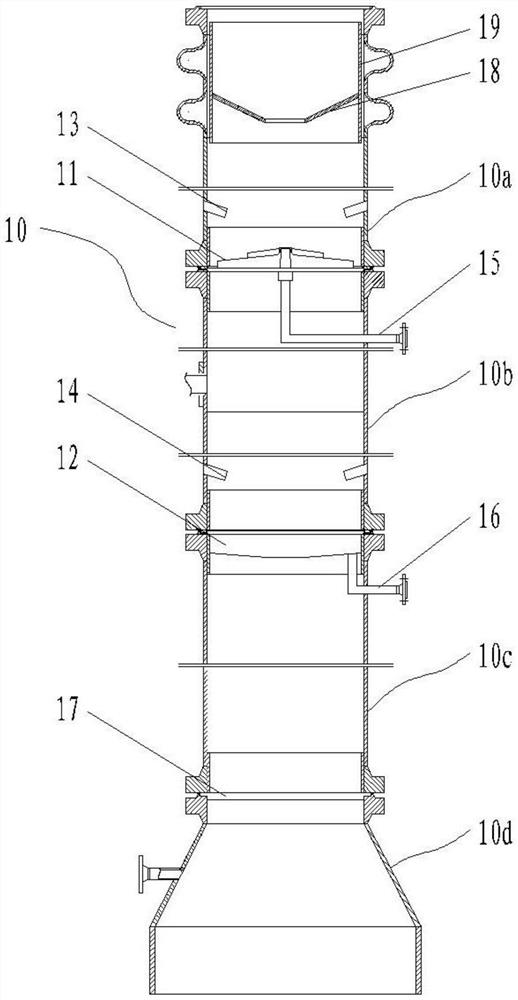

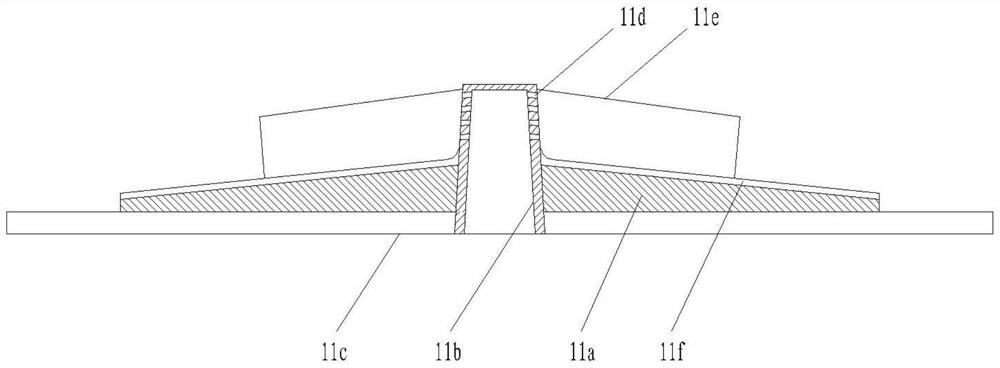

[0034]Wherein the vertical incineration tower comprises an incineration tower 10, and an upper combustion pan 11 and a lower combustion pan 12 are arranged up and down in the said incineration tower, and an upper combustion pan for use in conjunction with the upper combustion pan is arranged above the upper combustion pan in the said incineration tower. Device 13, a lower burner 14 for cooperating with the lower burning disc is arranged above the lower burning disc, the upper burning disc has an upper drain hole, the lower burning disc has a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com