Rotor bearing block, and wind turbine comprising rotor bearing block

A technology for wind turbines and bearing housings, applied in wind engines, engines, wind power generation, etc., can solve problems such as hindering wind turbines, achieve investment cost and service life cost advantages, ensure replacement, and compact design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

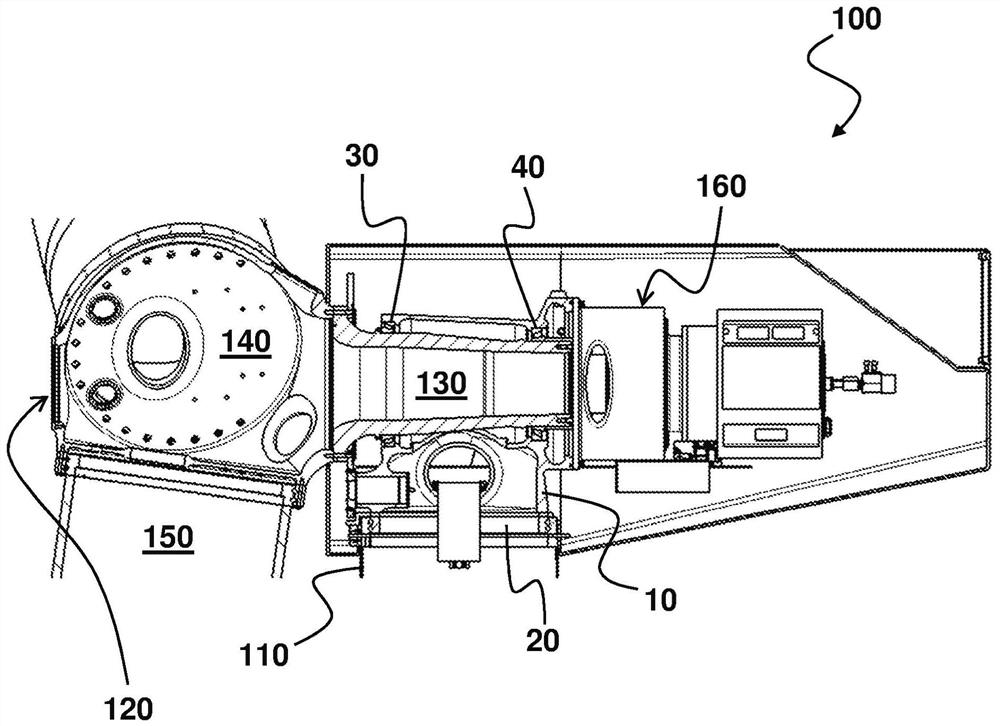

[0041] figure 1 A schematic sectional view of a wind turbine in the nacelle region is shown, which is particularly preferably configured according to the invention as a leeward rotor.

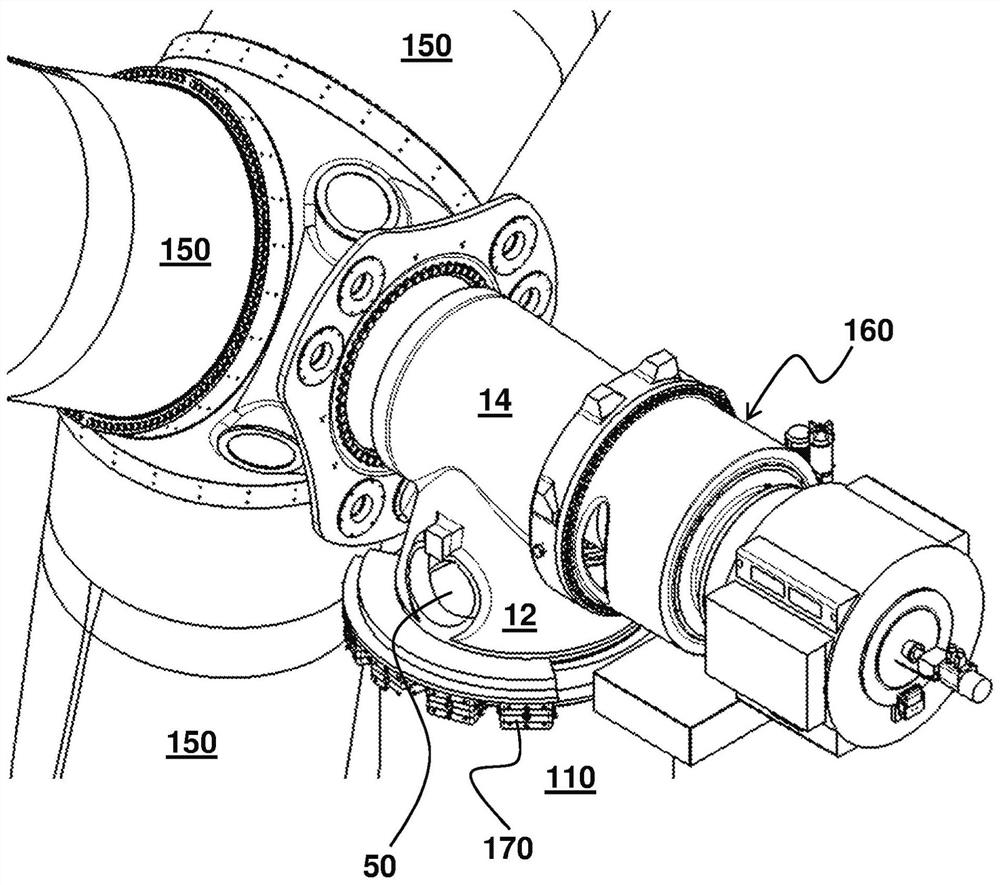

[0042] A particularly preferably constructed wind turbine 100 has a tower 110; a rotor bearing housing 10 constructed according to the invention arranged on the tower 110; a rotor 120 with a rotor shaft 130 mounted in the rotor bearing housing 10; rotor hub 140 flanged to rotor shaft 130 ; and a plurality of rotor blades 150 coupled to rotor hub 140 ; and a generator received by generator base 160 and coupled to rotor shaft 130 .

[0043] It can be clearly seen that the rotor bearing housing 10 is designed with a circular tower connection 20 which forms the upper bearing unit of the azimuth system. The rotor bearing housing 10 also accommodates two ring bearings 30 , 40 which are spaced apart from each other and are designed as tapered roller bearings. As shown in the cross-sectional view, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com