Dry corn cob threshing residue recovery equipment based on intelligent manufacturing

A technology of intelligent manufacturing and recycling equipment, applied in threshing equipment, applications, agricultural machinery and machinery, etc., can solve the problem of waste of human resources, inability to automatically recycle corn cobs, etc., and achieve the effect of saving human resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

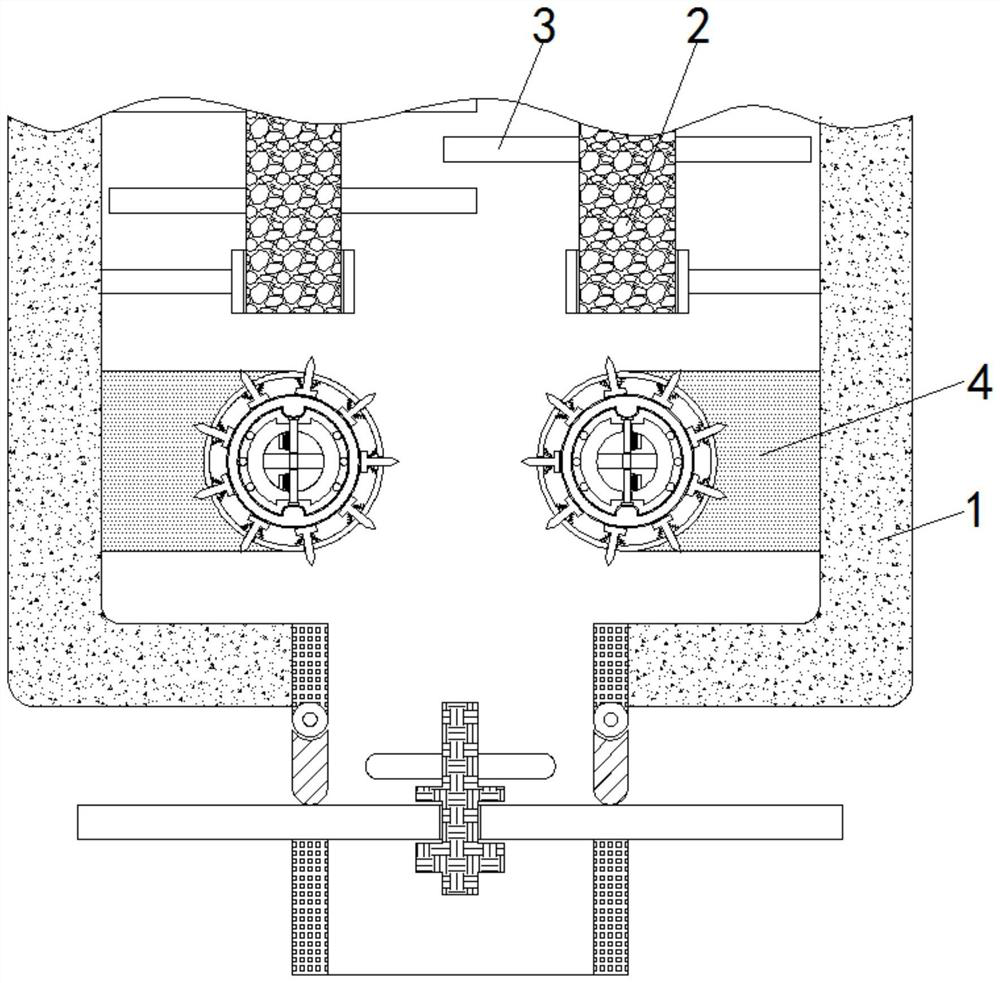

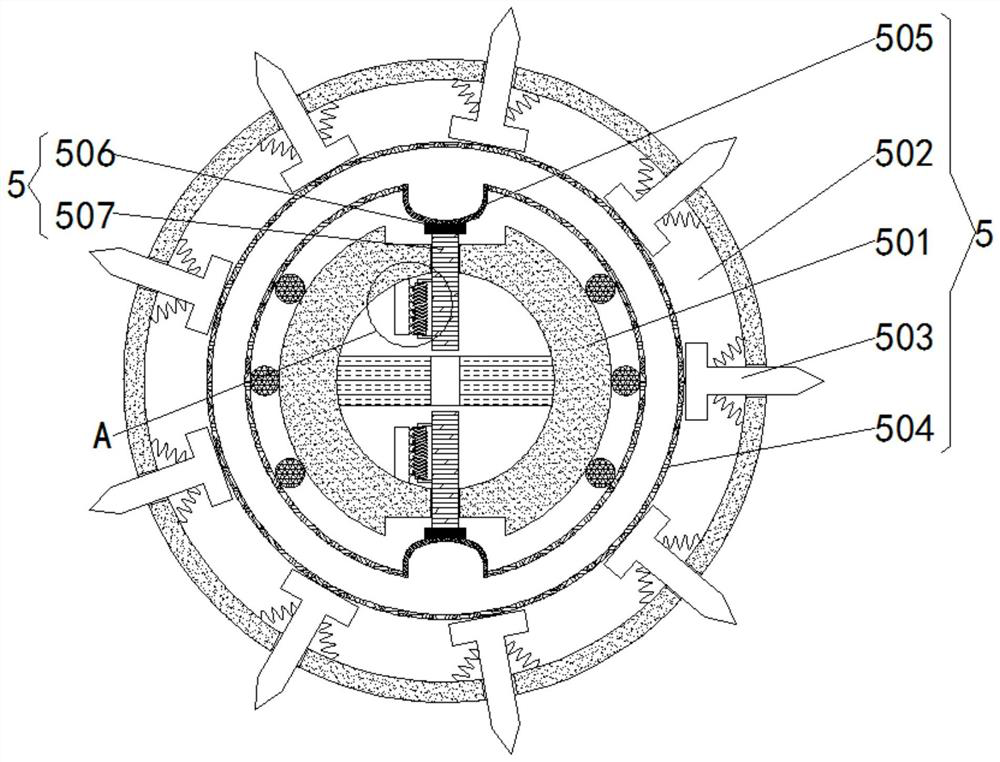

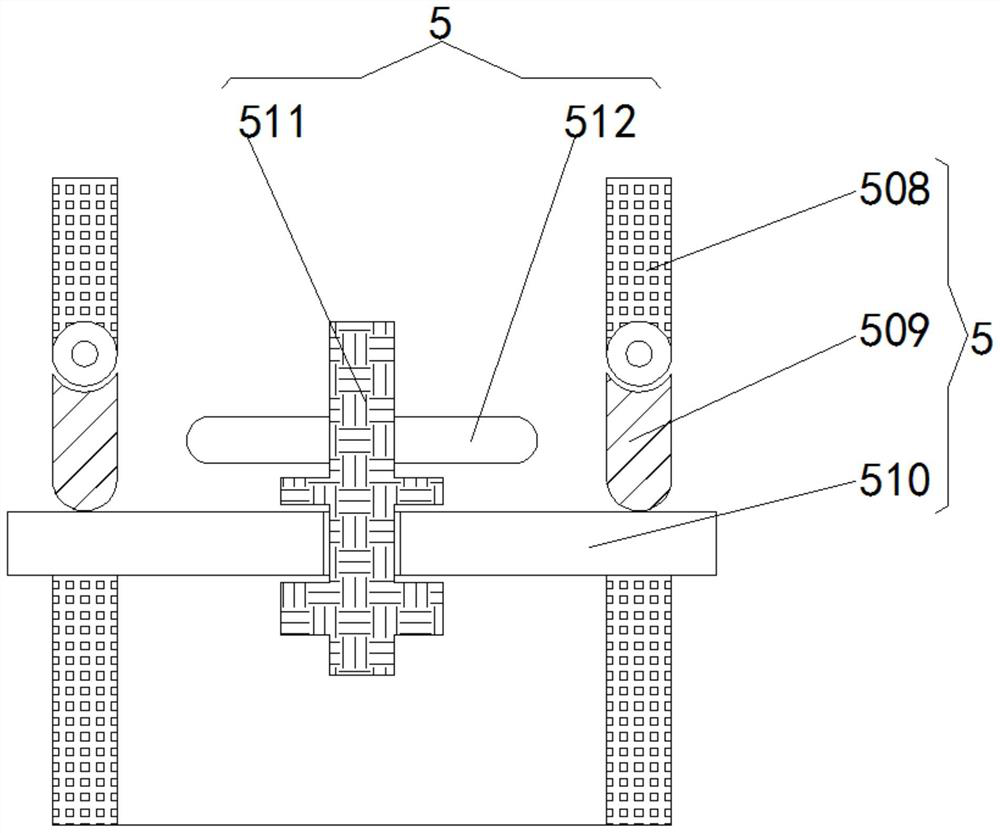

[0026] Example 1: Please refer to Figure 1-3 , a dry corn cob threshing residue recovery equipment based on intelligent manufacturing, comprising a threshing box 1, a rotating shaft 2 is arranged inside the threshing box 1, a staggered rod 3 is fixedly connected to the side of the rotating shaft 2, and a support plate 4 is arranged below the rotating shaft 2 , the surface of the support plate 4 is rotatably connected with a detection recovery mechanism 5, and a detection wheel 501 is fixedly installed inside the detection recovery mechanism 5, and an annular cavity 502 is provided inside the detection wheel 501, and a thimble 503 is interspersed on the side of the annular cavity 502, and the thimble The side of 503 is provided with a tension spring, and the other side is connected with the inner wall of the annular cavity 502, so that the thimble 503 can be automatically reset, and the corn cob is repeatedly inserted. The side of the thimble 503 away from the wheel center is s...

Embodiment 2

[0028] Example 2: Please refer to Figure 1-4, a dry corn cob threshing residue recovery equipment based on intelligent manufacturing, comprising a threshing box 1, a rotating shaft 2 is arranged inside the threshing box 1, a staggered rod 3 is fixedly connected to the side of the rotating shaft 2, and a support plate 4 is arranged below the rotating shaft 2 , the surface of the support plate 4 is rotatably connected with a detection recovery mechanism 5, and a detection wheel 501 is fixedly installed inside the detection recovery mechanism 5, and an annular cavity 502 is provided inside the detection wheel 501, and a thimble 503 is interspersed on the side of the annular cavity 502, and the thimble 503 is provided with an annular balloon 504 on the side close to the wheel center. The inner wall of the annular balloon 504 is fixedly connected with a convex airbag 505. The side of the convex airbag 505 close to the wheel center is fixedly connected with an insulating rod 506. A...

Embodiment 3

[0030] Example 3: Please refer to Figure 1-4 , a dry corn cob threshing residue recovery equipment based on intelligent manufacturing, comprising a threshing box 1, a rotating shaft 2 is arranged inside the threshing box 1, a staggered rod 3 is fixedly connected to the side of the rotating shaft 2, and a support plate 4 is arranged below the rotating shaft 2 , the surface of the support plate 4 is rotatably connected with a detection recovery mechanism 5, and a detection wheel 501 is fixedly installed inside the detection recovery mechanism 5, and an annular cavity 502 is provided inside the detection wheel 501, and a thimble 503 is interspersed on the side of the annular cavity 502, and the thimble The side of 503 is provided with a tension spring, and the other side is connected with the inner wall of the annular cavity 502, so that the thimble 503 can be automatically reset, and the corn cob is repeatedly inserted. The side of the thimble 503 away from the wheel center is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com