Method for automatically adjusting height of brush according to automatically measured plate thickness

An automatic measurement and automatic adjustment technology, applied in the cleaning method of tools, measuring devices, chemical instruments and methods, etc., can solve problems such as jamming and low efficiency, so as to speed up production efficiency, reduce scrap rate, and improve intelligence The effect of manufacturing capacity

Pending Publication Date: 2022-04-05

晶影光学技术(常熟)有限公司

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] The purpose of the present invention is to provide a method for automatically adjusting the height of the brush according to the automatically measured plate thickness, so as to solve the problem that the existing brush-type cleaning machines proposed in the above-mentioned background technology all clean PCBs according to needs when they are in use. Board thickness, manual adjustment or semi-automatic adjustment of the height of the cleaning brush to meet the cleaning effect of the brush cleaning machine, low efficiency and prone to card board problems

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

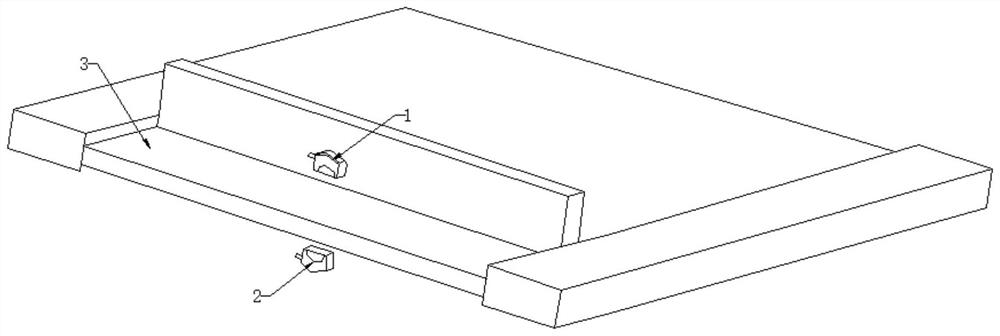

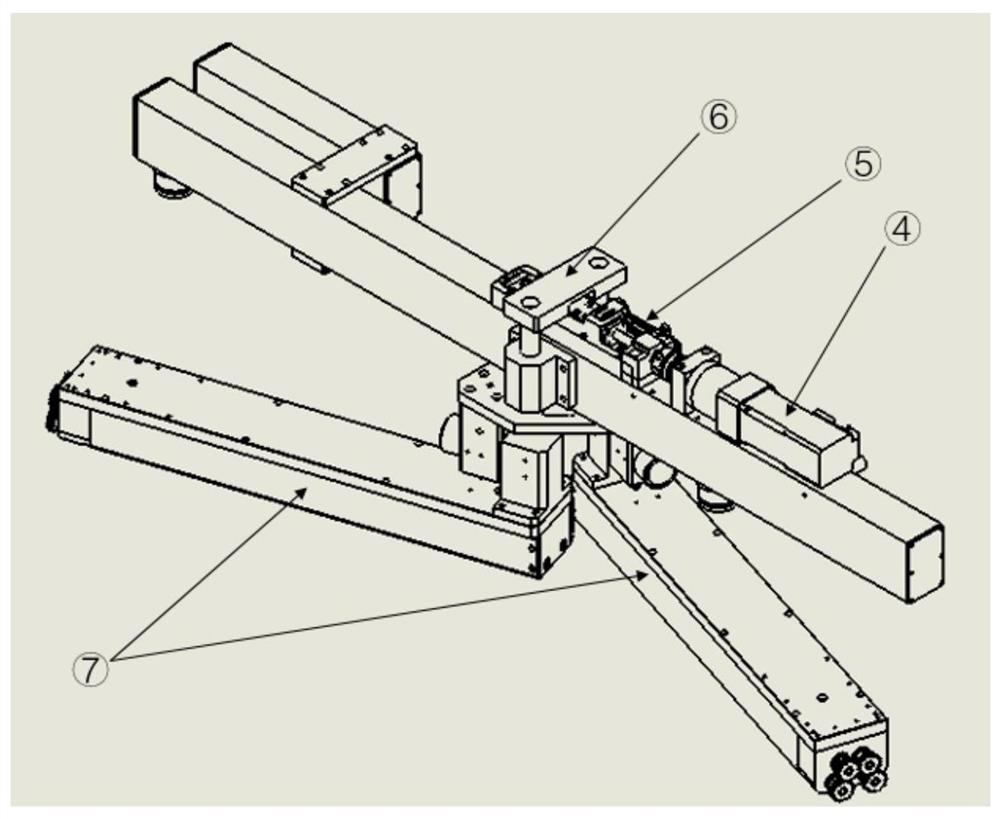

[0020] see Figure 1-2 , the present invention provides a technical solution: a method for automatically adjusting the height of the brush according to the automatically measured plate thickness, the specific steps of the method for automatically adjusting the height of the brush according to the automatically measured plate thickness are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the technical field of automatic control positioning, and particularly relates to a method for automatically adjusting the height of a brush according to automatically measured plate thickness, which comprises the following specific steps of: 1, adopting two sets of non-contact laser distance measuring sensors, the method comprises the following steps of: automatically measuring the thickness of a PCB (Printed Circuit Board) which passes through a brush type cleaning machine, and recording a distance value D0 between probes of two sets of laser distance measuring sensors which are vertically mounted up and down; the values of the upper laser distance measuring sensor and the lower laser distance measuring sensor transmit the distance from the probe to the PCB to the analog input of the PLC or the RS485 communication module through analog quantity or RS485 signals for data acquisition, the thickness value of the PCB does not need to be input manually, the situation that an operator forgets to input the thickness value is avoided, the rejection rate is reduced, the height of the brush does not need to be adjusted manually, the production efficiency is improved, and the production cost is reduced. The control is automatically completed, manual operation is not needed, and the intelligent manufacturing capacity of a factory is greatly improved.

Description

technical field [0001] The invention relates to the technical field of automatic control and positioning, in particular to a method for automatically adjusting the height of a brush according to the automatically measured plate thickness. Background technique [0002] Static electricity has potential safety hazards to products, especially for electronic products. For example, static electricity attracts particles in the air, which can easily cause short circuits between device leads. Therefore, removing static electricity and removing particles adsorbed on the surface of the product due to static electricity has become a must for product manufacturers. In production practice, most product manufacturers use brush cleaners to eliminate static electricity and particles. [0003] When the current brush-type cleaning machine is in use, the height of the cleaning brush is manually adjusted or semi-automatically adjusted according to the thickness of the PCB board to be cleaned t...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B08B1/02B08B13/00H05K3/26G01B11/06B08B1/20

Inventor 李治显葛立

Owner 晶影光学技术(常熟)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com