Automatic steel bar cutting device

A technology of automatic cutting device and steel bar is applied in the field of cutting device, which can solve the problems of occupying time and increasing the difficulty of work, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

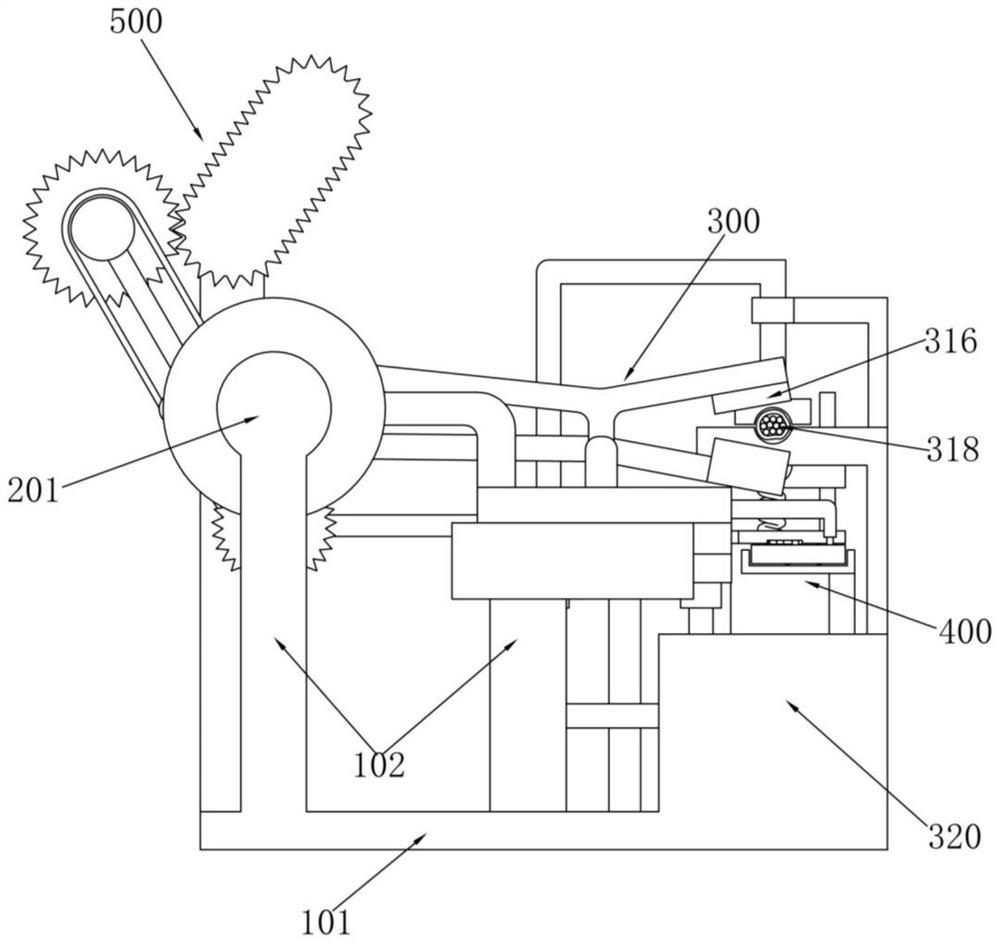

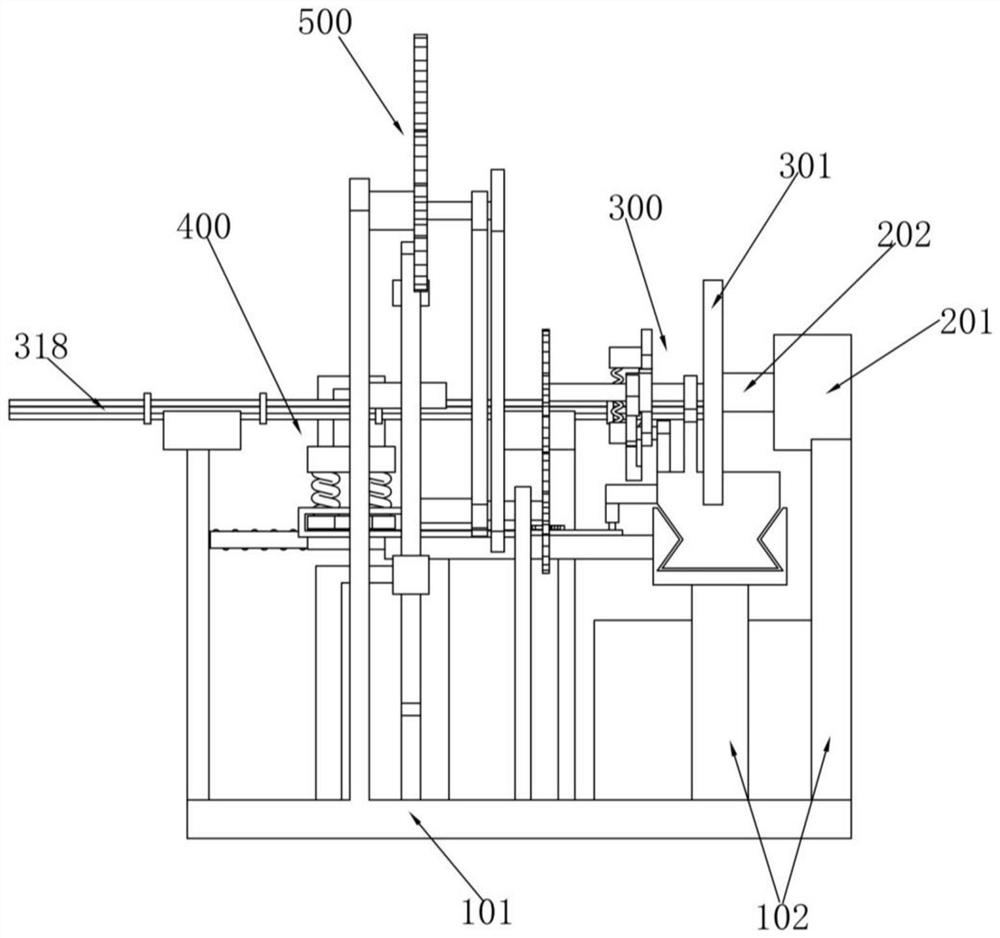

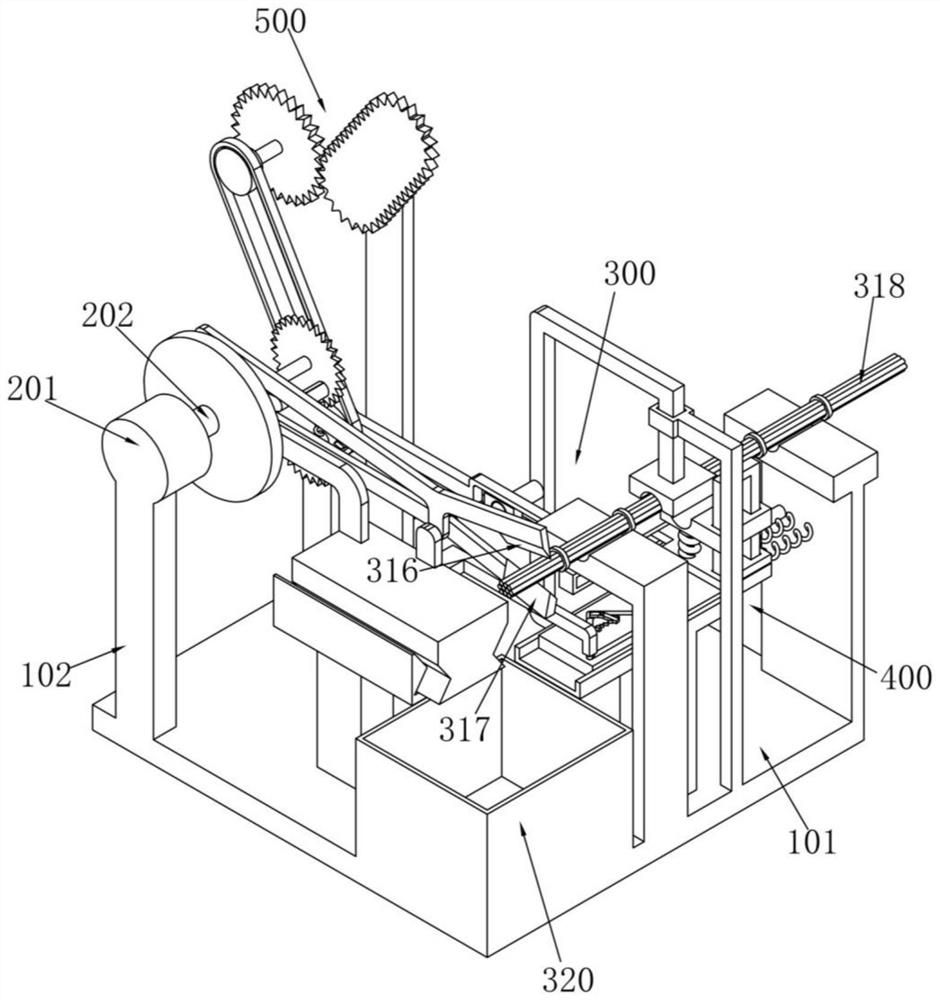

[0032] Such as figure 1 , 2 , shown in 3, a kind of steel bar automatic cutting device of the present invention comprises

[0033] Base plate 101, on which a plurality of brackets 102 are fixed;

[0034] A first guillotine 316, which is installed on the bracket 102, and the first guillotine 316 can cut the steel bars 318;

[0035] The cutting mechanism 300 is installed on the bracket 102 , and the cutting mechanism 300 realizes the cutting action of the first guillotine 316 by driving the cam mechanism through the motor 201 , so as to complete the cutting of the steel bar 318 .

[0036] The motor 201 of the present invention drives the cutting mechanism 300 through its output shaft 202 to realize the shearing action of the first guillotine 316, and realizes the cutting of the steel bar 318 through the shearing action of the first guillotine 316 .

[0037] Wherein, the bottom plate 101 can be placed on a horizontal surface such as the ground or a desktop;

[0038] Wherein,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com