Continuous beam spraying maintenance system

A maintenance system and beam body technology, applied in auxiliary molding equipment, ceramic molding machines, manufacturing tools, etc., can solve the problems of increasing water resources waste, weakening the water absorption capacity of concrete surface, reducing water resources utilization rate, etc., to improve utilization rate. , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

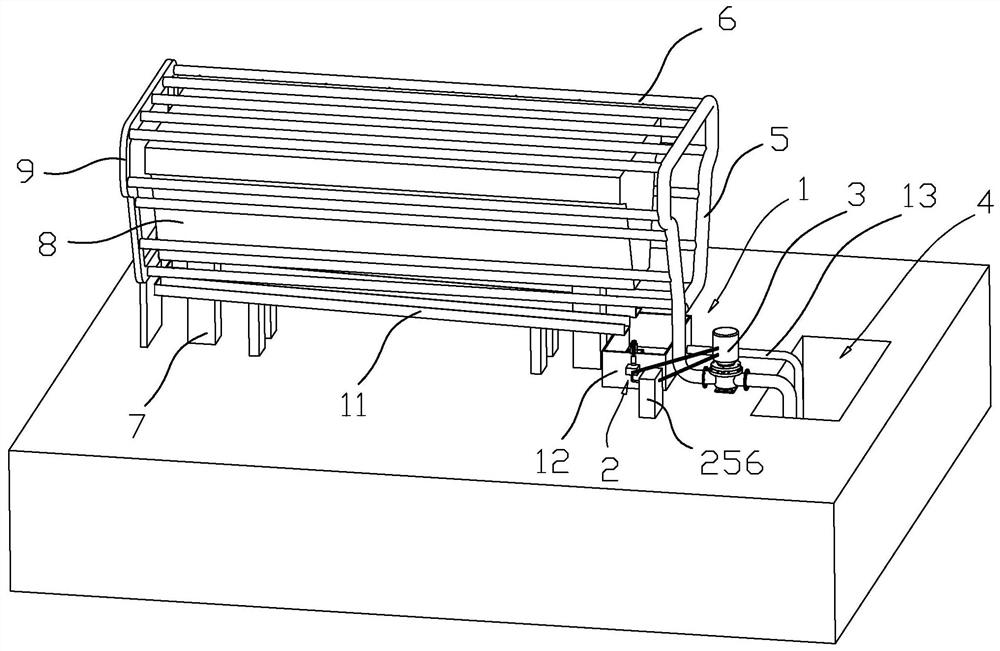

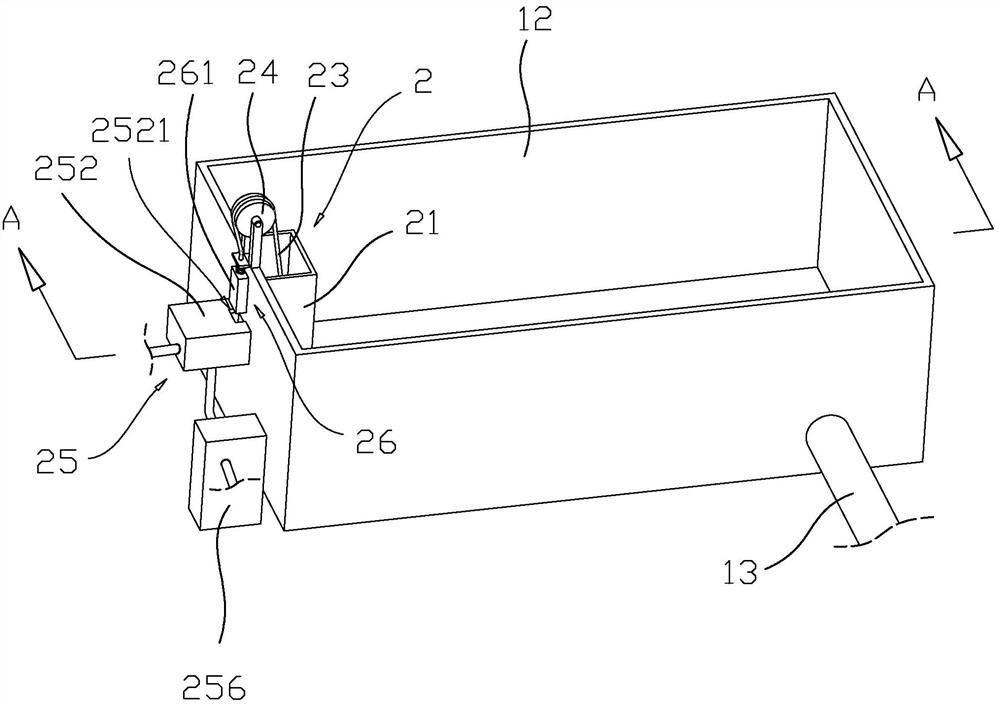

[0030] The following is attached Figure 1-4 The application is described in further detail.

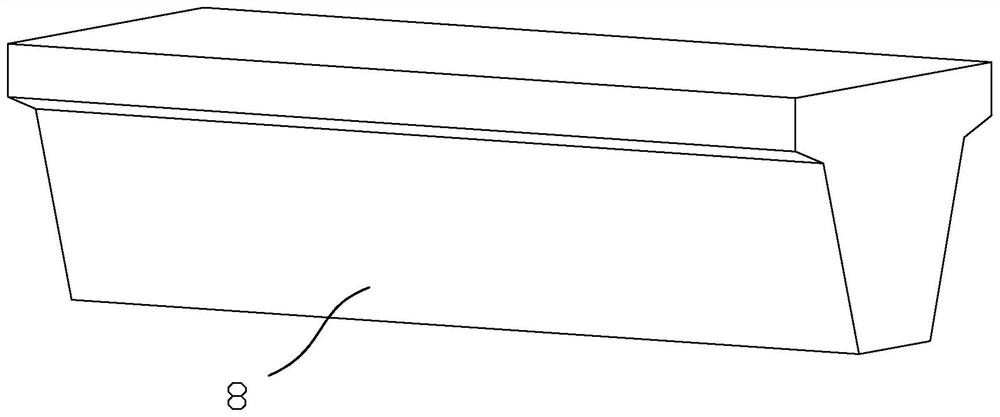

[0031] The embodiment of the application discloses a continuous beam spray maintenance system. refer to figure 1 and figure 2As shown, the spray maintenance system includes a booster pump 3, a reservoir 4, a main pipe 5, a horizontal spray pipe 6, a support frame 9, a water collecting device 1 and a control device 2. A support block 7 is placed on the ground, and a continuous beam body 8 is mounted on the support block 7. The reservoir 4 is located at one end of the continuous beam body 8. The reservoir 4 is opened under the ground, and the booster pump 3 is fixedly arranged on the reservoir. On one side of the pool 4, the water inlet of the booster water pump 3 is connected to the reservoir 4, and the water outlet of the booster water pump 3 is connected to the main pipe 5, and the main pipe 5 is wound around the outside of the longitudinal section of the continuous beam body 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com