Multilayer co-extrusion transparent high-impact antistatic polycarbonate composite material and preparation method thereof

A polycarbonate, composite material technology, applied in electrostatic, chemical instruments and methods, layered products, etc., can solve the problems of low strength and transparency, poor antistatic effect, etc., to achieve short cycle, short production process, high strength and the effect of shock properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

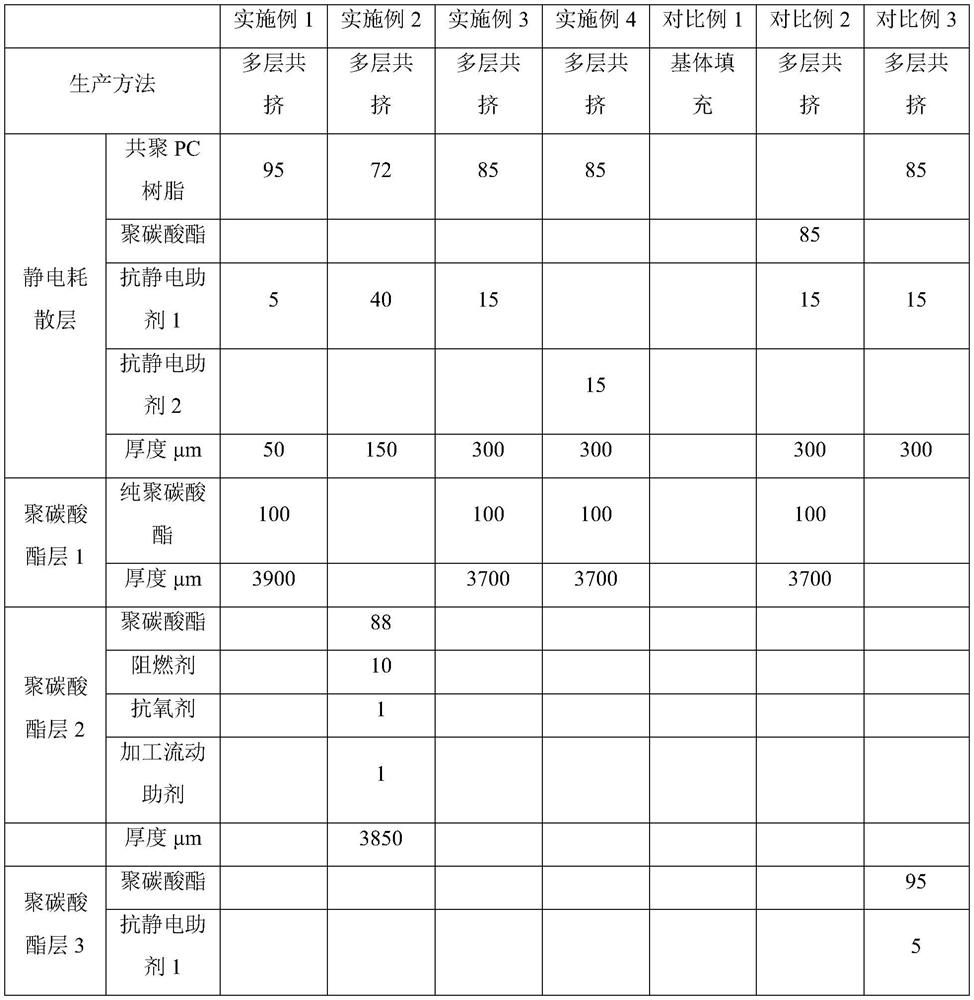

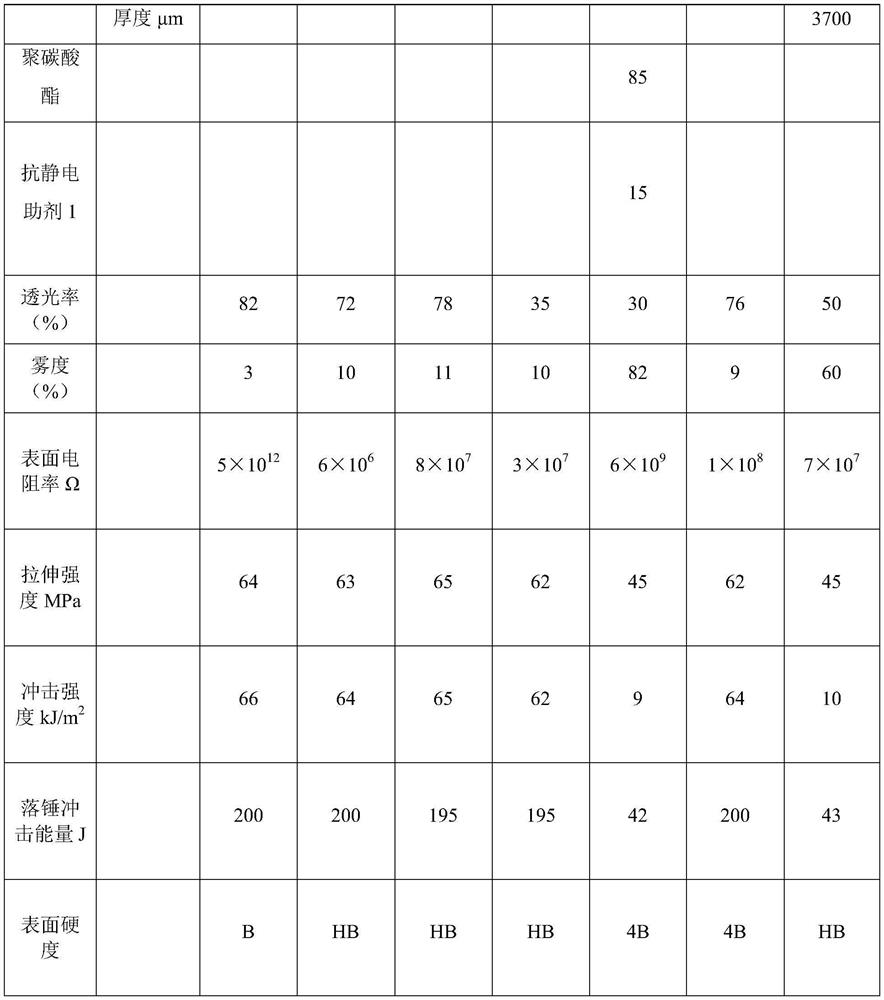

Embodiment 1-4 and comparative example 2-3

[0045] The preparation method of embodiment 1-4 and comparative example 2-3 polycarbonate composite material comprises the steps:

[0046] According to the ratio in Table 1, extrude the components of the static dissipative layer through a twin-screw extruder at 240-280°C to obtain an antistatic masterbatch, dry it at 120°C for 2 hours, and put it into the auxiliary machine of the single-screw extruder. Put pure polycarbonate or functional polycarbonate (corresponding to the polycarbonate layer) into the main unit of the single-screw extruder, extrude the auxiliary unit of the single-screw extruder and the main unit of the single-screw extruder together to obtain a polycarbonate composite material . The temperature of each section of the single-screw extruder is 230, 250, 260, 270, 260, 250, and 230° C., the rotation speed of the extrusion screw is 300-500 rpm, and the rotation speed of the granulator is 40 rpm.

[0047] The functional polycarbonate is obtained by extruding th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com