Solvent-free coating composition used for electron beam curing film forming and having shape memory function and preparation method thereof

An electron beam curing, solvent-free coating technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of intolerance to nail marks, white edges, and easy rebound, etc., to solve the problem of nail resistance and rebound Or the effect of white edge and low porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

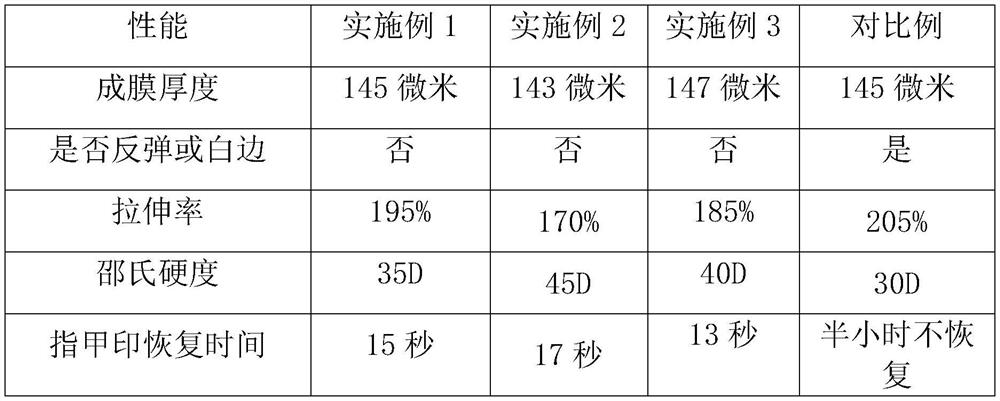

Examples

Embodiment 1

[0022] A solvent-free coating composition for electron beam curing and film formation with shape memory function, made of the following raw materials in parts by weight:

[0023] 30 parts by mass of modified shape memory polyurethane, 30 parts by mass of polyurethane acrylic resin (Changxing DR-U312) with double reaction functionality, 15 parts by monomer (THFA), 15 parts by monomer (HEA), 0.5 part of auxiliary agent (BYK333), 0.5 part of auxiliary agent (Digo 370).

[0024] Preparation method: 30 parts by mass of modified shape-memory polyurethane, 30 parts by mass of polyurethane acrylic resin (Changxing DR-U312) with double-reactive functionality, 15 parts by monomer (THFA), 15 parts by monomer (HEA), auxiliary agent (BYK333 ) and 0.5 part of additive (Tego 370) were mixed and stirred uniformly to prepare a solvent-free coating for electron beam curing and film formation with shape memory function.

Embodiment 2

[0026] A solvent-free coating composition for electron beam curing and film formation with shape memory function, made of the following raw materials in parts by weight:

[0027] 40 parts by mass of modified shape-memory polyurethane, 20 parts by mass of polyurethane acrylic resin with three-reactive functionality (Boxing B-301), 25 parts of monomer (THFA), 14 parts of monomer (HDDA), 0.5 part of additive (BYK111) , 0.5 part of auxiliary agent (Di Gao 2100).

[0028] Preparation method: 40 parts by mass of modified shape-memory polyurethane, 20 parts by mass of polyurethane acrylic resin with three-reaction functionality (Boxing B-301), 25 parts of monomer (THFA), 14 parts of monomer (HDDA), auxiliary agent ( BYK111) 0.5 part, additive (Tego 2100) 0.5 part were mixed and stirred evenly to prepare a solvent-free coating for electron beam curing and film formation with shape memory function.

Embodiment 3

[0030] A solvent-free coating composition for electron beam curing and film formation with shape memory function, made of the following raw materials in parts by weight:

[0031] 35 parts by mass of modified shape memory polyurethane, 25 parts by mass of polyurethane acrylic resin (Meiyuan PU2034C) with double reaction functionality, 16 parts by monomer (IBOA), 24 parts by monomer (ACMO), 0.25 parts of auxiliary agent (BYK349), 0.25 part of auxiliary agent (BYK349), Agent (Di Gao 2300) 0.25 parts.

[0032] Preparation method: 35 parts by mass of modified shape-memory polyurethane, 25 parts by mass of polyurethane acrylic resin with dual-reaction functionality (Meiyuan PU2034C), 16 parts of monomer (IBOA), 24 parts of monomer (ACMO), and auxiliary agent (BYK349) 0.25 parts and 0.25 parts of additive (Tego 2300) were mixed and stirred evenly to prepare a solvent-free coating for electron beam curing and film formation with shape memory function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com