Stepped heating device for phenolic fiber preparation

A stepped heating, phenolic fiber technology, applied in the direction of rayon heat treatment, rayon support, etc., can solve the problems of long time consumption and low safety, and achieve the effect of fast limit and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

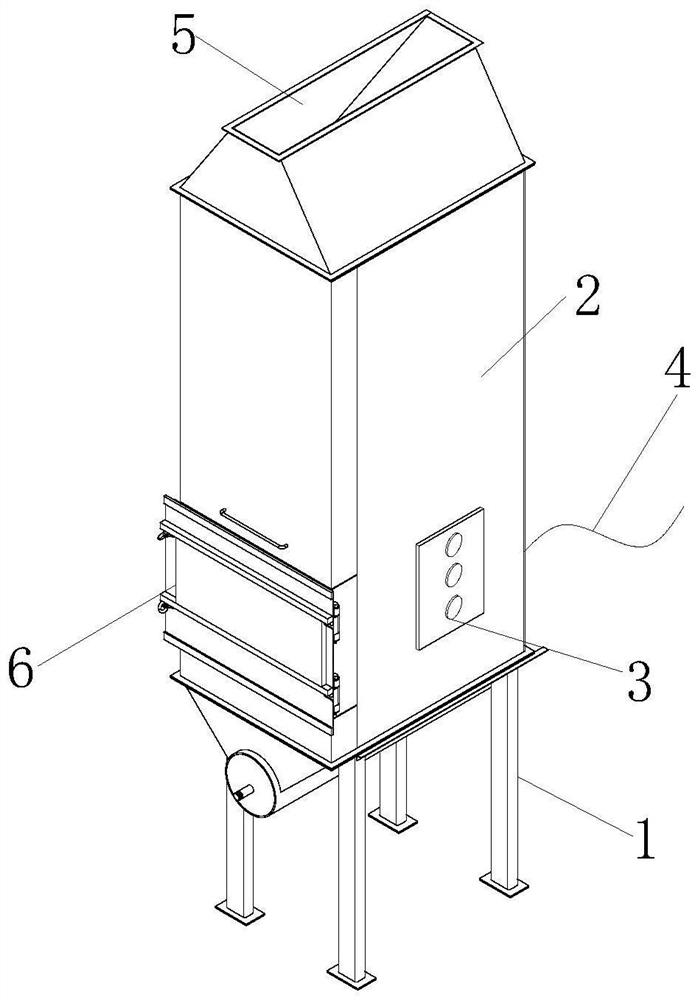

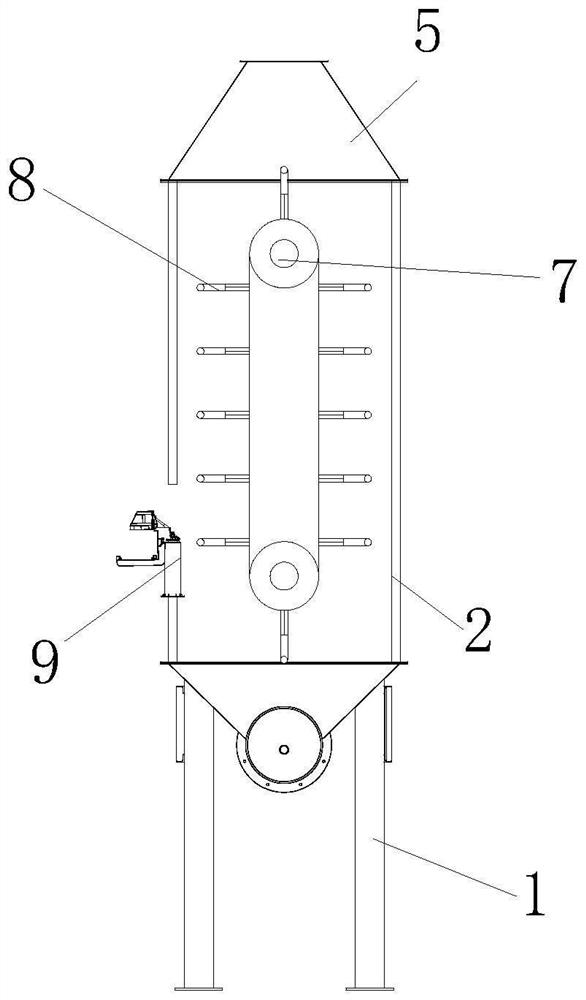

[0035] see figure 1 and figure 2 , the present invention provides a stepped heating device for phenolic fiber preparation through improvement, including a support frame 1, a heating frame 2, a control panel 3, a power supply wire 4, an exhaust pipe 5, a through window 6, and a transmission module 7 , the supporting plate 8 and the conveying mechanism 9, the support frame 1 is fixed to the bottom of the heating frame 2, the right end of the heating frame 2 is provided with a control panel 3, the conveying mechanism 9 is installed on the left end of the heating frame 2, and the rear end of the heating frame 2 is fixed with a power lead 4 , the heating frame 2 is connected to the bottom of the exhaust pipe 5, the front end of the heating frame 2 is equipped with a through window 6, the inner side of the heating frame 2 is provided with a transfer module 7, and the upper end of the transfer module 7 is equidistantly distributed with supporting plates 8.

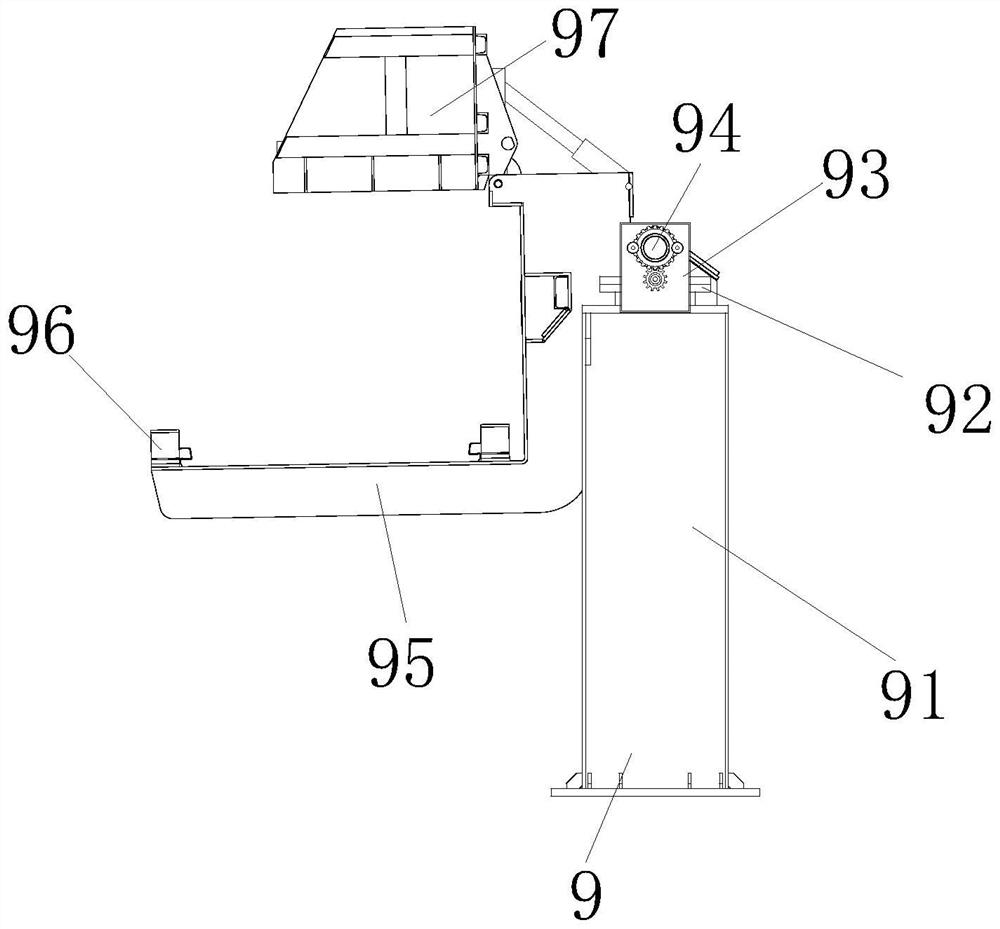

[0036] see image 3 an...

Embodiment 2

[0042] The present invention provides a stepped heating device for the preparation of phenolic fibers through improvement. There are two guide wheels 935, and the guide wheels 935 are arranged oppositely along the left and right sides of the upper end of the driven gear 934, which is beneficial to make the driven gear 934. The role of the gear 934 to rotate smoothly, the driving gear 933 and the driven gear 934 are distributed parallel to each other, which is beneficial to play the role of driving the driven gear 934 to rotate.

[0043] The present invention provides a stepped heating device for the preparation of phenolic fibers through improvement, and its working principle is as follows;

[0044] First, before use, the stepped heating device for phenolic fiber preparation is placed horizontally, so that the support frame 1 is fixed and supported for the device;

[0045] Second, when in use, connect the external power supply through the power lead 4 to provide power to the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com