Threaded soft sealing gate valve capable of effectively reducing fluid resistance and using method

A fluid resistance and soft sealing technology, applied in the valve's device for absorbing fluid energy, sliding valve, valve details, etc., can solve problems such as affecting the efficiency of pipeline medium transportation, large resistance coefficient of gate valve cavity material, affecting normal pipeline transportation, etc. To achieve the effect of improving the efficiency of medium circulation in the gate valve, improving the convenience of maintenance, and ensuring normal transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

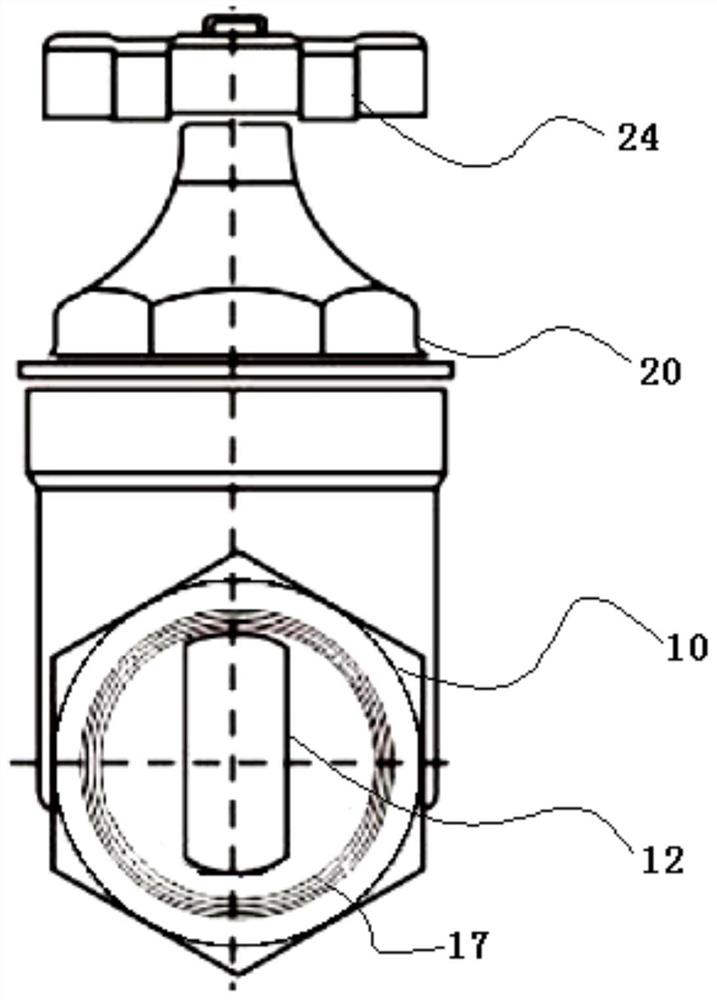

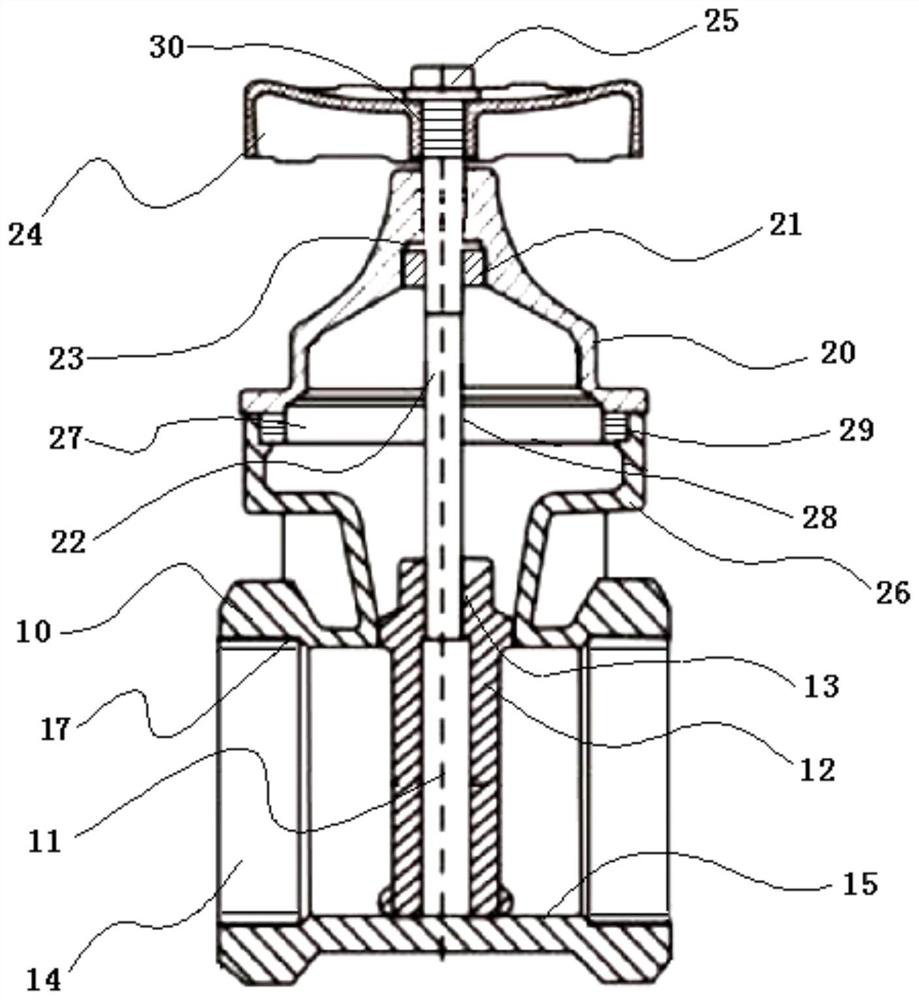

[0028] refer to figure 1 and figure 2 As shown, a soft-sealed gate valve with a silk mouth that can effectively reduce fluid resistance includes a valve body 10 and a bonnet 20, the bonnet 20 is arranged on the upper end of the valve body 10, and the upper part of the inner wall of the bonnet 20 is arranged A limit sleeve 21, the valve stem 22 is set inside the limit sleeve 21, the upper end of the valve stem 22 is connected with a turntable 24, and the lower end is connected with a valve plate 11, and the valve stem 22 is fixedly provided with a limit Block 23, the limiting block 23 is in contact with the upper end surface of the limiting sleeve 21, the top of the valve stem 22 is provided with a threaded groove 30, and the threaded groove 30 is provided with a bolt 25 matching the threaded groove 30, and the turntable 24 and the valve stem 22 are fixed by the bolt 25, specifically, the bolt 25 passes through the through hole in the middle of the turntable 24 and is inserte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com