Heating device for dry-cooking machine based on electric heating glass and using method of heating device

A technology of electric heating glass and dry cooking machine, which is applied in the direction of dryer, drying, drying gas arrangement, etc., can solve the problem of low heating limit of PTC heater, achieve fixed installation efficiency, improve heating efficiency, and increase heating temperature The effect of the cap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

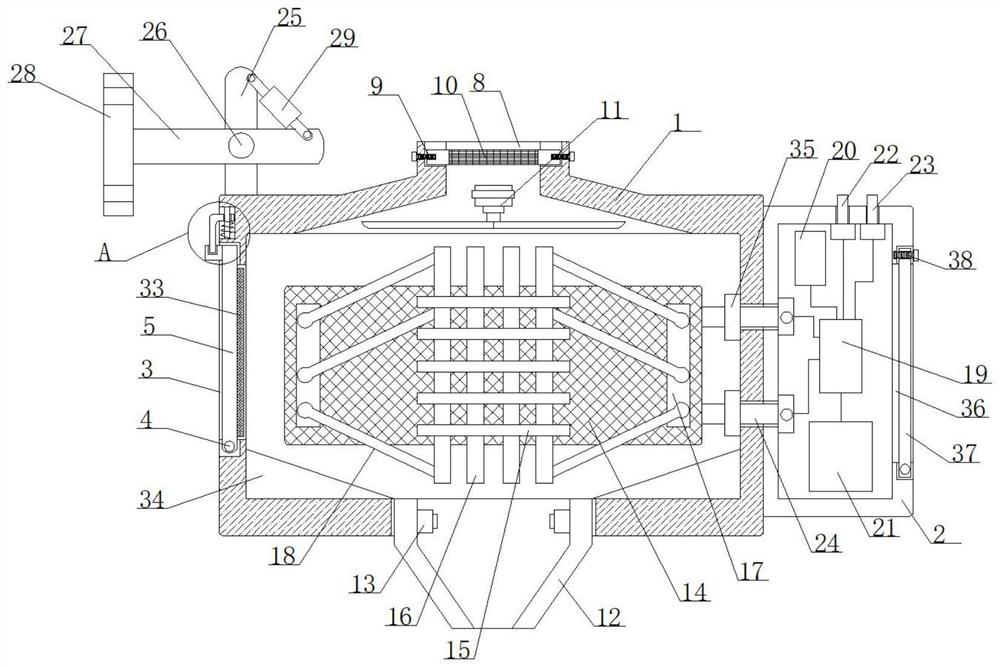

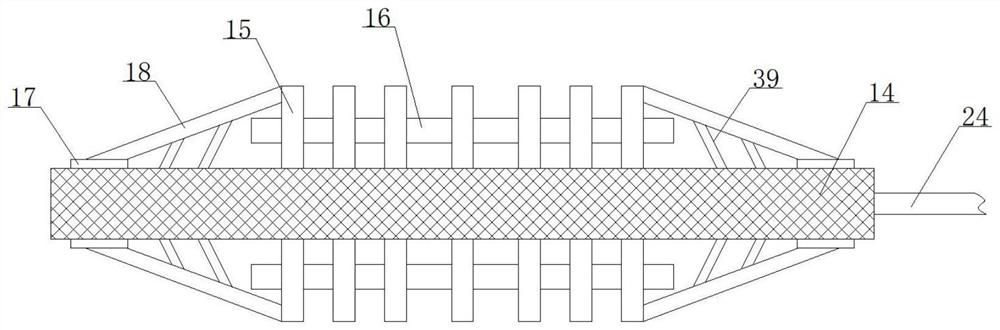

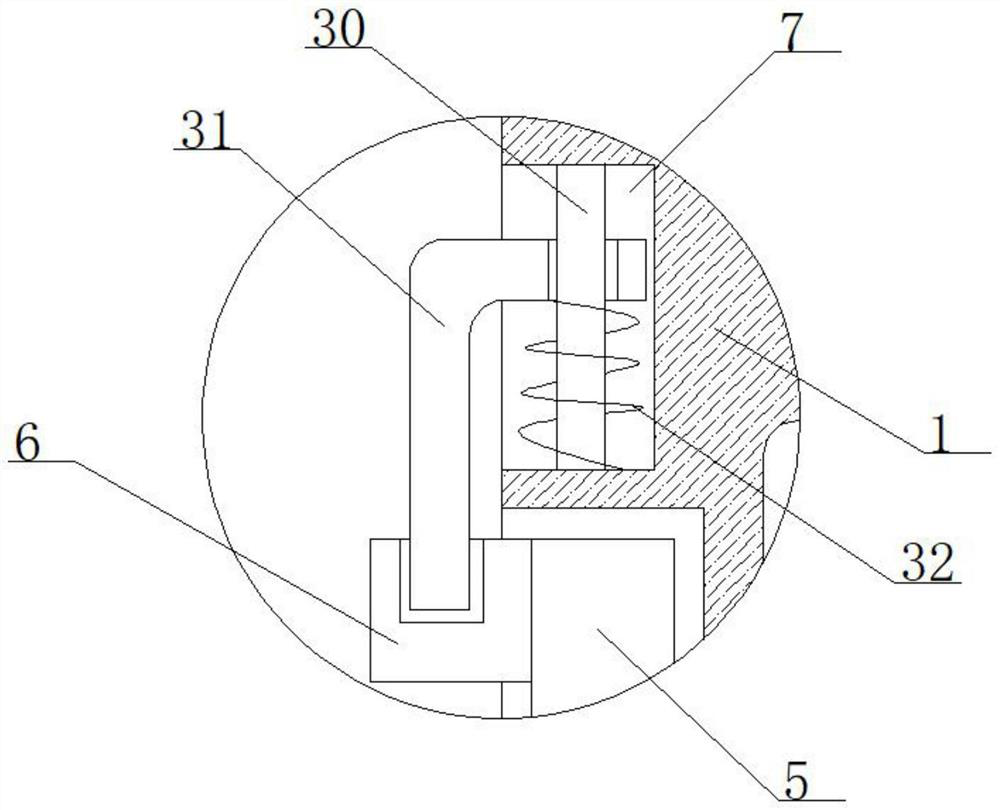

[0037] refer to Figure 1-4 , a heater for a dry cooker based on electrothermal glass, including a main casing 1 and a control box 2, the side of the control box 2 away from the main casing 1 is provided with a maintenance port 36 to facilitate maintenance of the electrothermal glass sheet 14, the maintenance port 36 is rotatably connected with a maintenance plate 37, the top of the maintenance plate 37 is fixedly connected with the inner wall of the maintenance port 36 through fastening bolts 38, and the inner bottom of the main housing 1 is fixedly connected with a plurality of deflectors 34, which facilitates the export of hot air and controls The box 2 is fixedly connected to the outer wall of the main casing 1, and the top of the main casing 1 away from the control box 2 is fixedly connected with an installation mechanism, which is convenient for installing and fixing the main casing 1;

[0038] In the present invention, the installation mechanism includes a support rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com