Energy-saving injection molding machine with heat recovery function

A heat recovery and injection molding machine technology, applied in the field of plastic molding equipment, can solve the problems of waste heat waste, huge power consumption, low energy conversion efficiency, etc., achieve precise temperature control, increase the upper limit of heating temperature, and improve energy utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

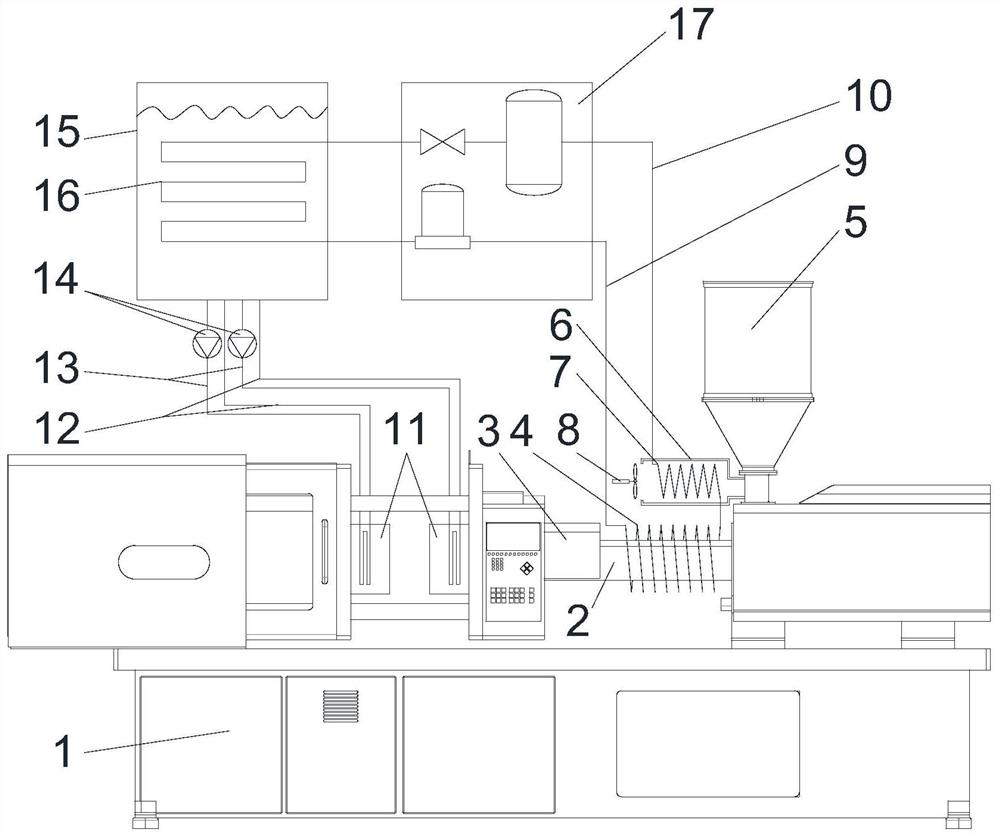

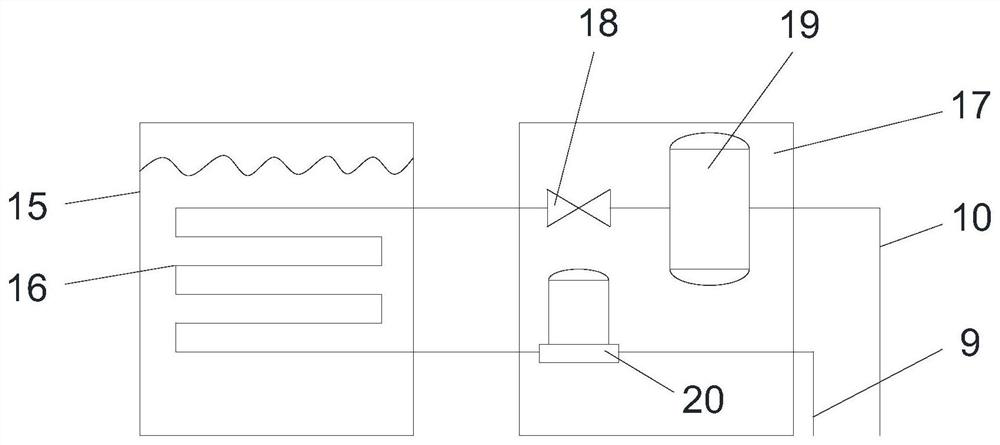

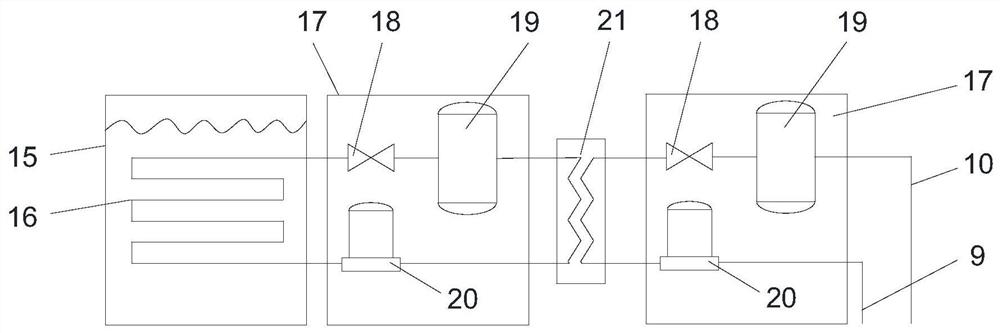

[0016] The present invention proposes an energy-saving injection molding machine with heat recovery function, such as figure 1 and figure 2 As shown, the device mainly includes: injection molding machine main body 1, barrel 2, heater 3, plasticizing coil 4, hopper 5, heat exchange cylinder 6, heat exchange coil 7, fan 8, heating pipe 9, heating return Pipe 10, mold 11, cooling return pipe 12, cooling pipe 13, circulation pump 14, water tank 15, water tank coil 16, heat pump 17, throttle valve 18, liquid tank 19 and compressor 20. Among them, the main body 1 of the injection molding machine is a general-purpose injection molding machine, the left side is the clamping mechanism, and the right side is the plasticizing mechanism. Except for the structure specified in this patent, the rest of the structure is the same as the general injection molding machine; the barrel 2 is the injection molding machine. The screw barrel of the main body 1; the heater 3 is a general-purpose elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com