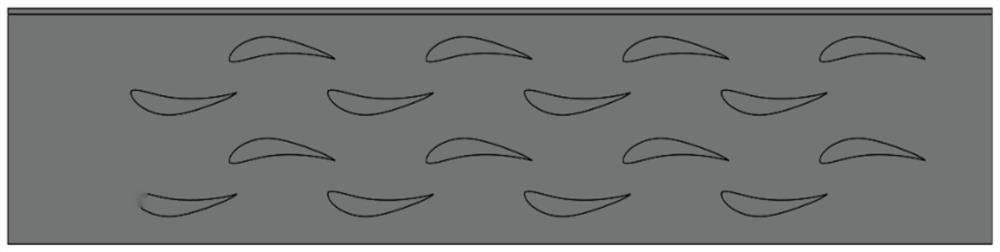

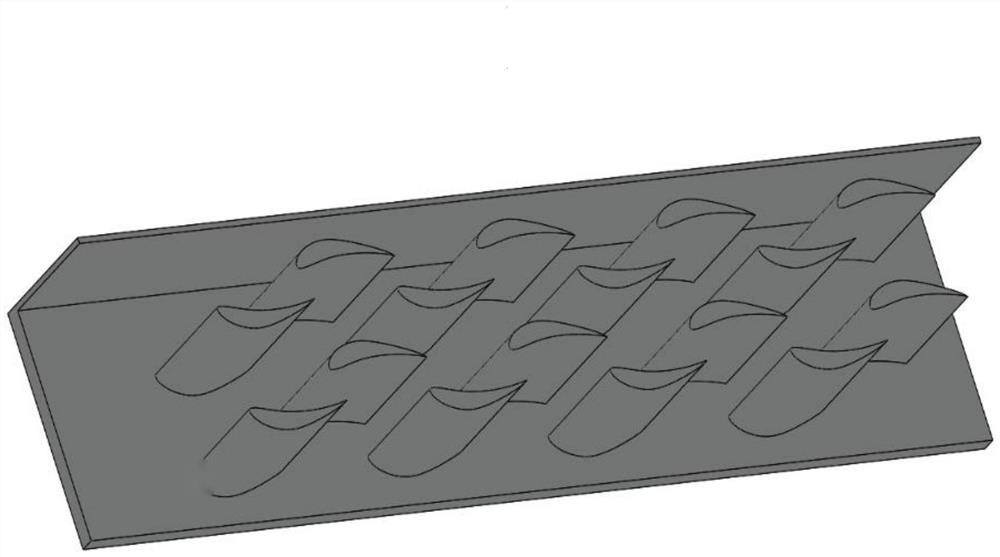

Mirror symmetry concave-convex wing type fin type PCHE flow channel

A mirror-symmetrical, fin-type technology, which is applied in the field of discontinuous airfoil fin flow channel and concave-convex airfoil fin type PCHE flow channel, can solve the problems of poor heat transfer performance and achieve improved heat transfer capacity and high heat transfer efficiency. Efficiency improvement, eddy current and backflow reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following will describe the technical solutions in the embodiments of the present invention in conjunction with the accompanying drawings in the embodiments of the present invention. It should be pointed out that the embodiments described below are all exemplary embodiments, not all embodiments, and are intended to clearly illustrate Technical characteristics and advantages of the present invention.

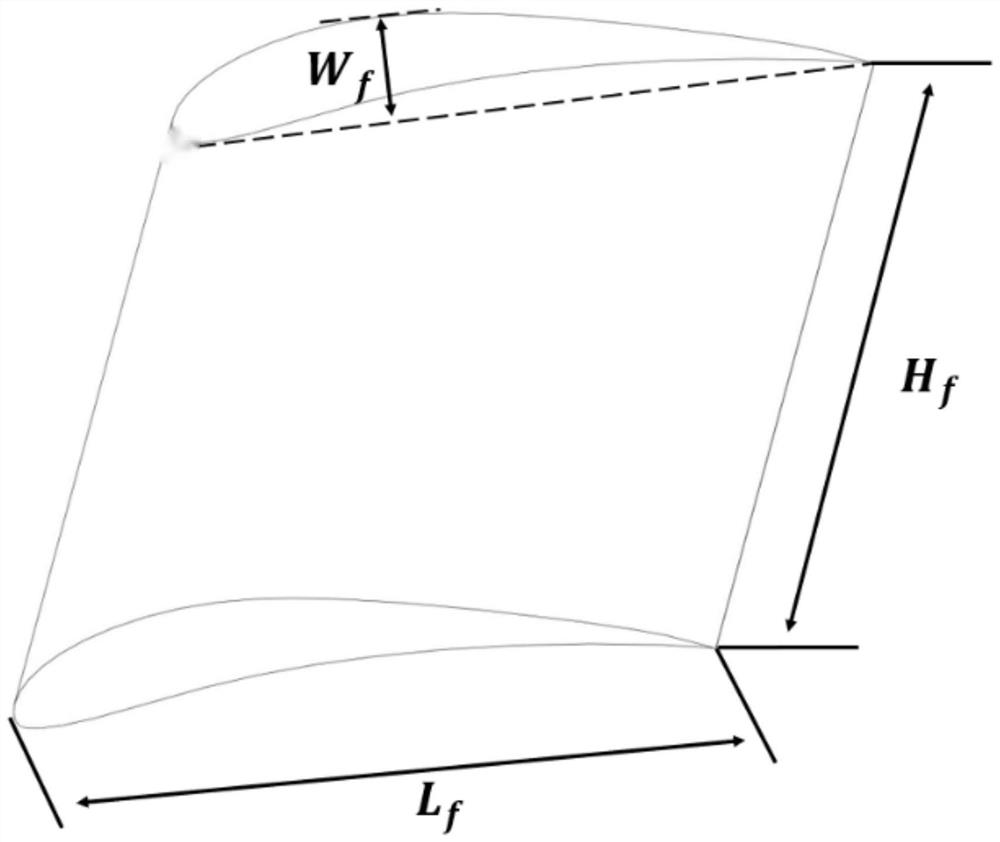

[0025] In the appendix of the embodiment of the present invention figure 1 In the description of , it should be understood that the term "transverse" refers to the direction of the coordinate axis X, "longitudinal" refers to the direction of the coordinate axis Z, and "transverse spacing" refers to the distance between the front edge of the unit body 1 and the unit body 3 in the direction of the coordinate axis X, "Longitudinal spacing" refers to the distance between the front edges of the unit body 1 and the unit body 2 in the direction of the coordinate axis Z, and "...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com