Pole piece processing device and lamination machine

A technology for processing devices and pole pieces, applied to measuring devices, non-aqueous electrolyte batteries, instruments, etc., can solve the problems of low efficiency of pole piece burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

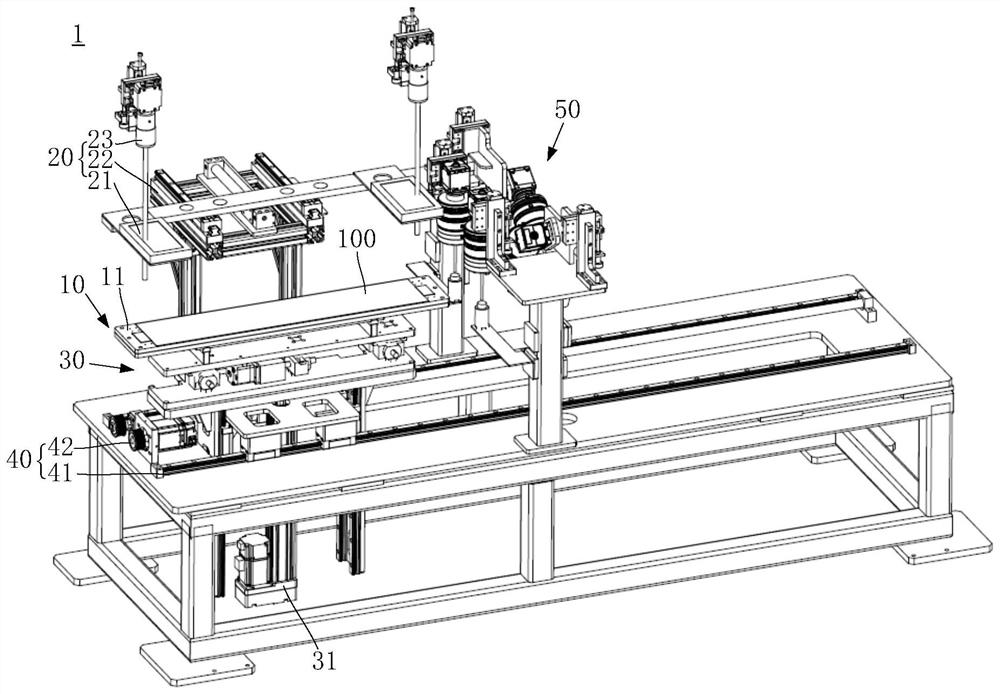

[0042] Such as figure 1 As shown, the present invention provides a pole piece processing device 1 for performing edge detection on cut pole pieces during the production process of laminated lithium battery cells.

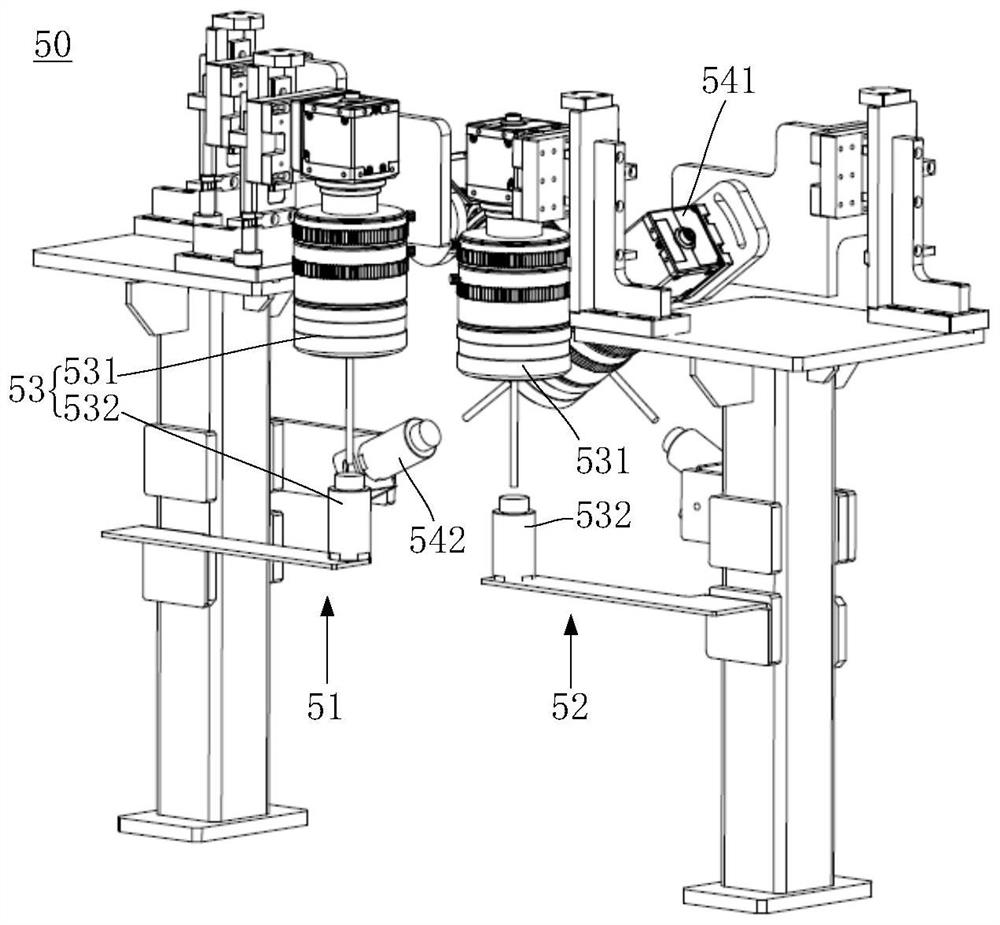

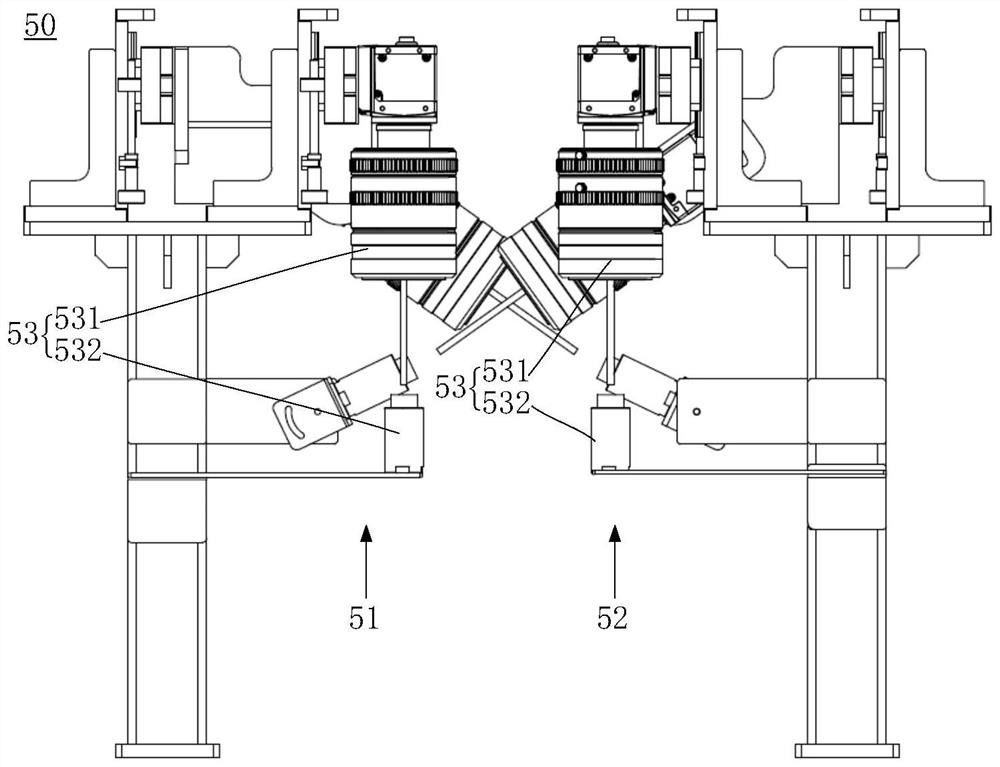

[0043] The pole piece processing device 1 mainly includes a pole piece carrying part 10 , a positioning mechanism 20 , a deviation correction mechanism 30 , a translation mechanism 40 and a detection mechanism 50 .

[0044] The pole piece carrying part 10 is configured to carry the cut pole piece 100 to be inspected. The pole piece bearing part 10 includes a bearing platform 11 , and the surface of the bearing platform 11 is also provided with adsorption holes for absorbing the pole piece 100 .

[0045] The positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com